WIRING

NOTE: All wiring must conform to applicable local codes, ordinances, and

regulations.

1. Install module wiring in accordance with the job drawings and appropri-

ate wiring diagrams.

2. Set the address on the module per job drawings.

3. Secure module to electrical box (supplied by installer), as shown in

Figure 2.

IMPORTANT: When using the FCM-1-REL for Class B applications, remove

Jumper (J1) and discard. The Jumper is located on the back as shown in

Figure 1B.

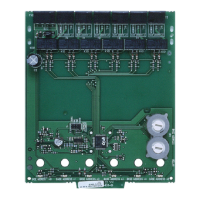

FIGURE 2. MODULE MOUNTING:

C1060-00

NO-460-002 1 I56-2992-004

FCM-1-REL Releasing Control Module

BEFORE INSTALLING

This information is included as a quick reference installation guide. Refer to

the control panel installation manual for detailed system information. If the

modules will be installed in an existing operational system, inform the opera-

tor and local authority that the system will be temporarily out of service. Dis-

connect power to the control panel before installing the modules.

NOTICE: This manual should be left with the owner/user of this equipment.

GENERAL DESCRIPTION

FCM-1-REL Releasing Control Modules are intended for use in intelligent, two-

wire systems, where the individual address of each module is selected using

the built-in rotary switches. This module is used to switch an external power

supply, which can be a DC power supply to a solenoid. It also supervises the

wiring to the connected load and reports the status to the panel as NORMAL,

OPEN, or SHORT CIRCUIT. The FCM-1-REL has two pairs of output termination

points available for fault-tolerant wiring and a panel-controlled LED indicator.

COMPATIBILITY REQUIREMENTS

To ensure proper operation, this module shall be connected to a compatible

Notifier system control panels only (list available from Notifier). In addition,

please refer to Notifier Device Compatibility document number 15378 for the

list of compatible solenoids.

MOUNTING

The FCM-1-REL mounts directly to 4-inch square electrical boxes (see Figure

2). The box must have a minimum depth of 2

1

/8 inches. Surface mounted elec-

trical boxes (SMB500) are available (for indoor dry applications only).

FIGURE 1A. CONTROLS AND FIGURE 1B. JUMPER LOCATION:

INDICATORS:

C1059-00 C0910-00

I56-2992-004

SPECIFICATIONS

SLC

Normal Operating Voltage: 15 to 32 VDC Nominal

Average Operating Current: 700µA (LED flashing)

Maximum Activation Current: 9.0 mA (red LED on)

External Supply

Normal Operating Voltage: 24 VDC Nominal

Maximum Line Loss: 2.3 VDC (total allowable loss from power supply to module and from module to solenoid)

Minimum Operating Voltage to Activate Solenoid: 18 VDC (at solenoid)

Standby Current: 6.4 mA

Activation Current: 10 mA

Maximum Activation Current: 2 A

Solenoid

Supervisory Loop Voltage: 3.3 V

Supervisory Loop Current (Normal): 30 mA

Maximum Activation Current: 2 A

Temperature Range: 14°F to 140°F (-10°C to 60°C)

Humidity: 10% to 95% RH Non-condensing

Dimensions: 4

1

/2˝ H × 4˝ W × 1

1

/4˝ D; (106 mm H × 108 mm W × 31 mm D)

Accessories: Wall cover plate (included); SMB500 Surface Mount Electrical Box (for indoor dry applications only)

12 Clintonville Road

Northford, CT 06472-1653

Phone: 203.484.7161

INSTALLATION AND MAINTENANCE INSTRUCTIONS

Loading...

Loading...