8

In a steam boiler, the tank supply must be connected to the boiler well below the minimum water level. A strainer

and drain valve should be installed at the boiler for periodic draining of scale and sludge. Banging and steam

bound traps will occur if the boiler water supplied to the heat exchanger has steam or is slightly above the low

water cut off.

The water heater heat exchanger cannot be used with non-barrier radiant pipe systems. Use with closed loop

boiler systems only.

C. COLD WATER INLET

Use both thread tape and pipe dope to connect an NPT female x ¾” minimum pipe adapter.

Dielectric fittings must be used on water heater connections.

A shut off valve between the city water supply and tank inlet is recommended for ease of service.

Exercise caution when soldering water heater connections, as outlet and inlet dip tubes are plastic.

It may be recommended to use a back flow preventer – check local codes. If a back flow preventer or a no return

valve is used, a thermal expansion tank must be installed on the cold water supply between the tank and valve. If

the tank is replacing a tankless coil in the boiler, disconnect coil plumbing and use the cold inlet pipe and hot

water outlet pipes for the water heater.

NOTE: DO NOT PLUG OUTLET IN TANKLESS COIL.

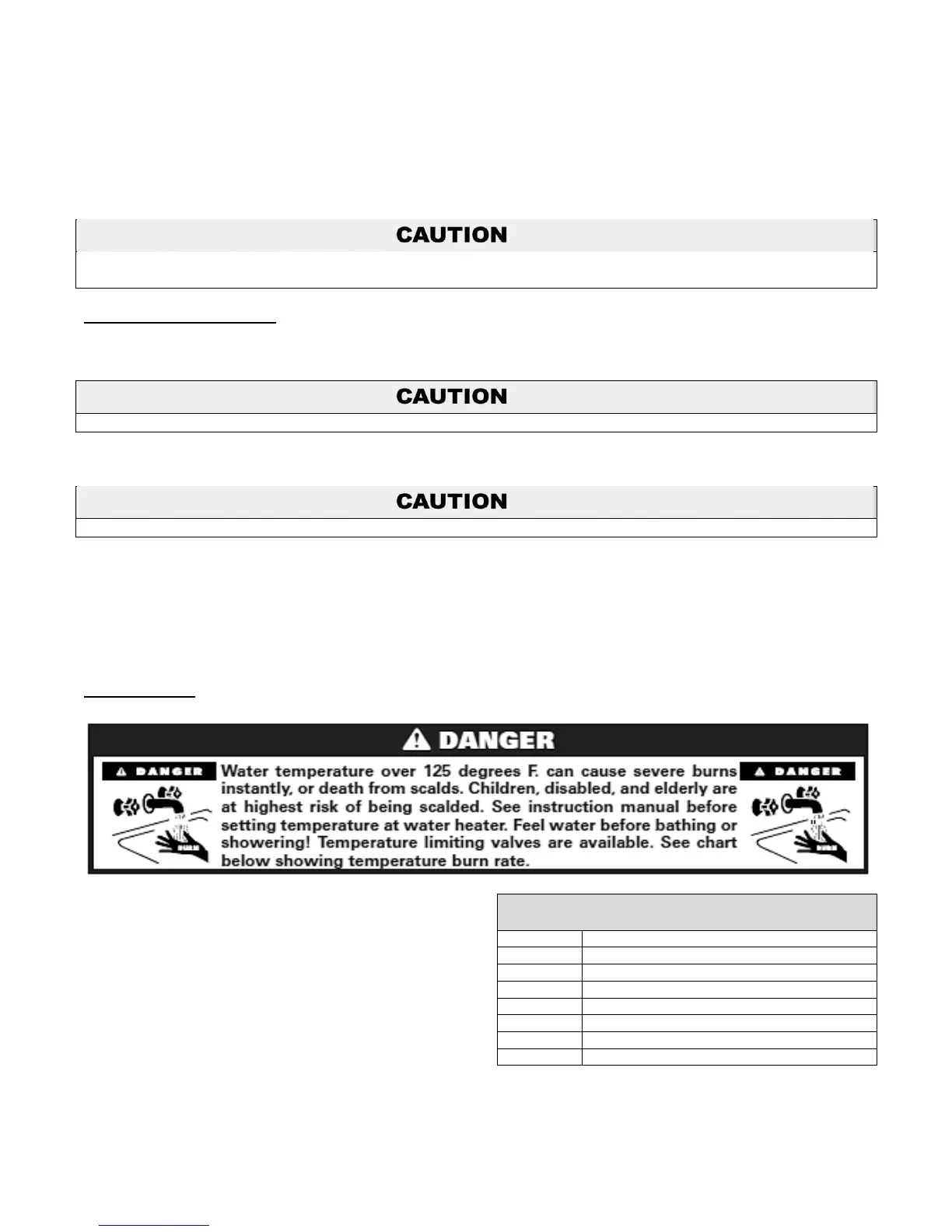

D. SCALDING

This heater can deliver scalding water. Be careful

whenever using hot water to avoid scalding injury. Certain

appliances, such as dishwashers and automatic clothes

washers may require increased water temperature. By

setting the thermostat on this heater to obtain the

increased water temperature required by these

appliances, you may create the potential for scald injury.

To protect against injury, you should install a mixing valve

in the water system. This valve will reduce point of

discharge temperature by mixing cold and hot water in

branch supply lines. Such valves are available from your local plumbing supplier.

APPROXIMATE TIME / TEMPERATURE

RELATIONSHIPS IN SCALDS

Loading...

Loading...