Maintenance Daily Weekly

Clean the external surfaces of the product with water. Refer to

To clean the product on

page 15

.

X

Clean the air filter. In dusty environments, clean the air filter more frequently. Refer to

To

clean and replace the air filter on page 16

.

X

Do a general inspection. Refer to

To do a general inspection on page 15

. X

Do a check of the engine oil level. X

Do a check of the drive belt. If it is necessary, adjust the tension of the drive belt. Refer to

To adjust the tension of the drive belt on page 15

.

X

Do a check of the machine stop button. Refer to

To do a check of the machine stop button

on page 7

.

X

Do a check of the blade guards. Refer to

To do a check of the blade guard on page 8

. X

Do a check of the muffler. X

Do a check of the cutting blade. Refer to

To clean the product on page 15

. X

Lubricate the grease nipples for the cutting depth adjustment. Refer to

To lubricate the

product on page 16

.

X

Do a check of the water flow. If the water flow is not sufficient, do a check of the water

supply holes in the blade guard. Remove unwanted material that causes a blockage to

the water supply holes.

X

To clean the product

WARNING: Use protective glasses.

When you clean the product, dirt and

harmful material can eject from the product.

CAUTION: A blocked air intake

decreases the performance of the product

and can cause the engine to become too

hot.

• Let the product become cool before you clean it.

• Do not clean electrical components with water.

• Use a weak cleaning agent. Put on protective gloves

to prevent skin irritation.

• Always clean all the equipment at the end of the

work day. Do not use a high-pressure washer to

clean the product.

• Remove blockage from all air openings.

• Clean all outlets, connections and cables with a dry

cloth.

• Remove unwanted material that causes a blockage

to the water supply holes in the blade guard.

• Clean around the fuel tank cap.

To do a general inspection

• Make sure that the nuts and screws on the product

are tightened.

• Make sure that the cables on the product are not in a

position where they can become damaged.

• Make sure that there are no fuel or oil leaks.

• Make sure that the seals for the fuel tank cap are not

damaged.

• Examine the fuel hose. Replace the fuel hose if it is

damaged or worn.

• Examine the water hoses for leakage. Do not

operate a product that has damaged water hoses.

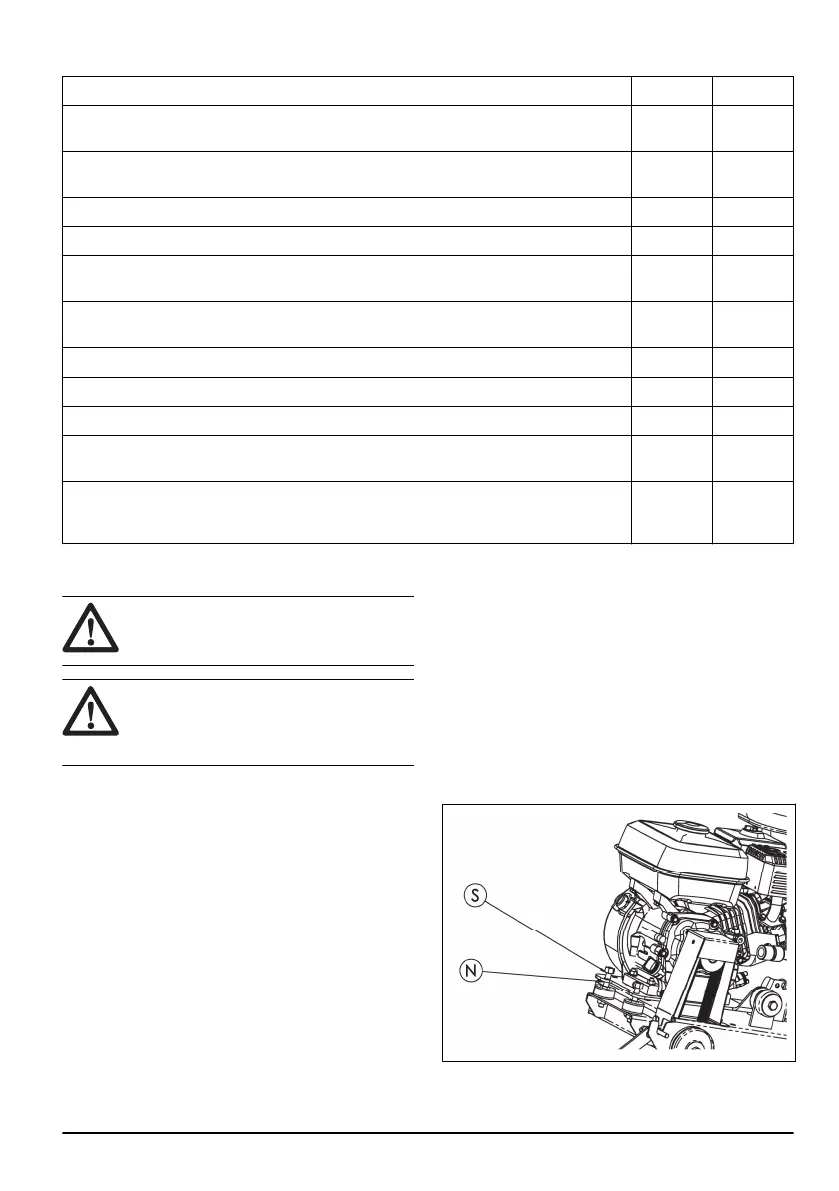

To adjust the tension of the drive belt

1. Loosen the 2 nuts (S) and remove the drive belt

cover.

2. Make sure that the drive belt is not damaged.

1919 - 002 - 23.01.2023 15

Loading...

Loading...