3-4 powermax190c Service Manual

MAINTENANCE

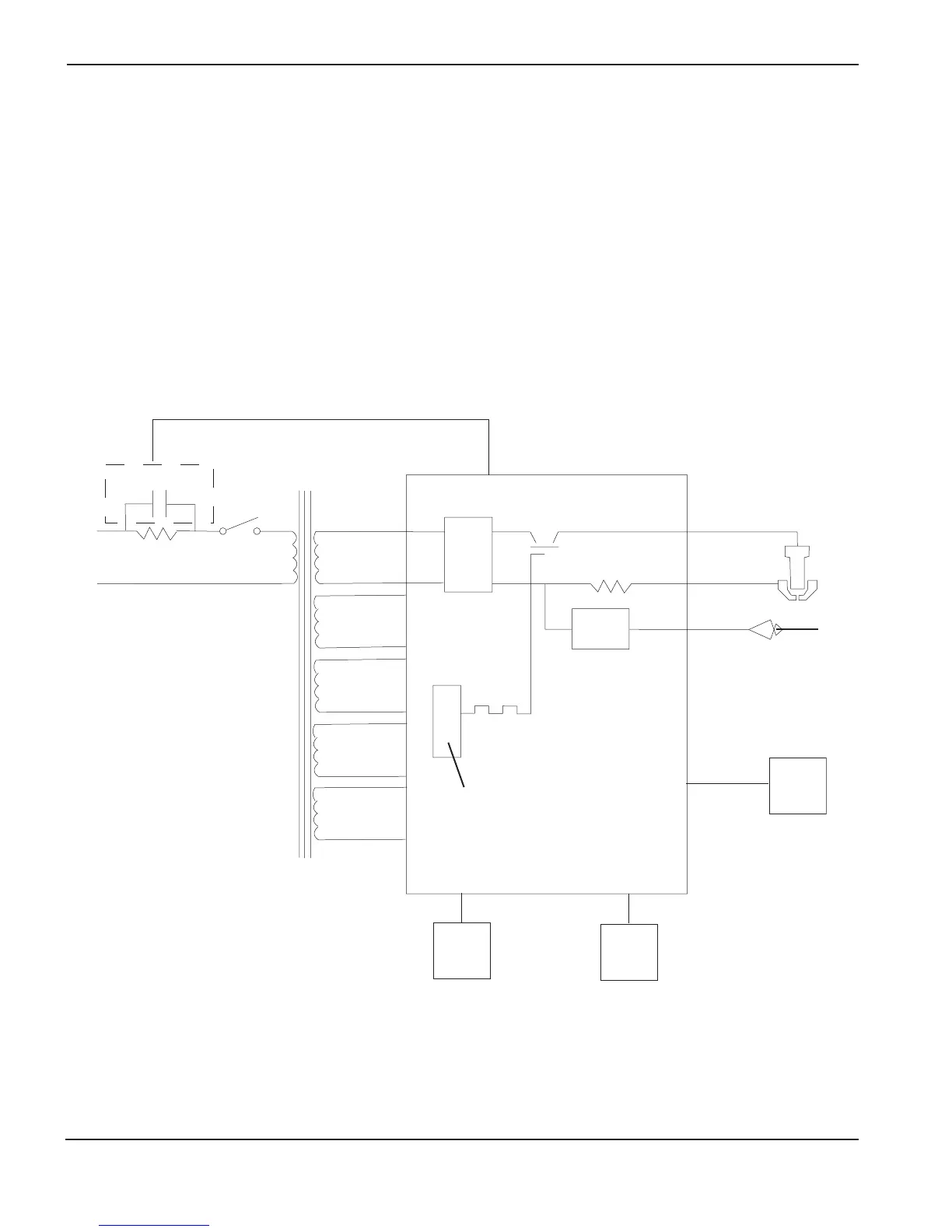

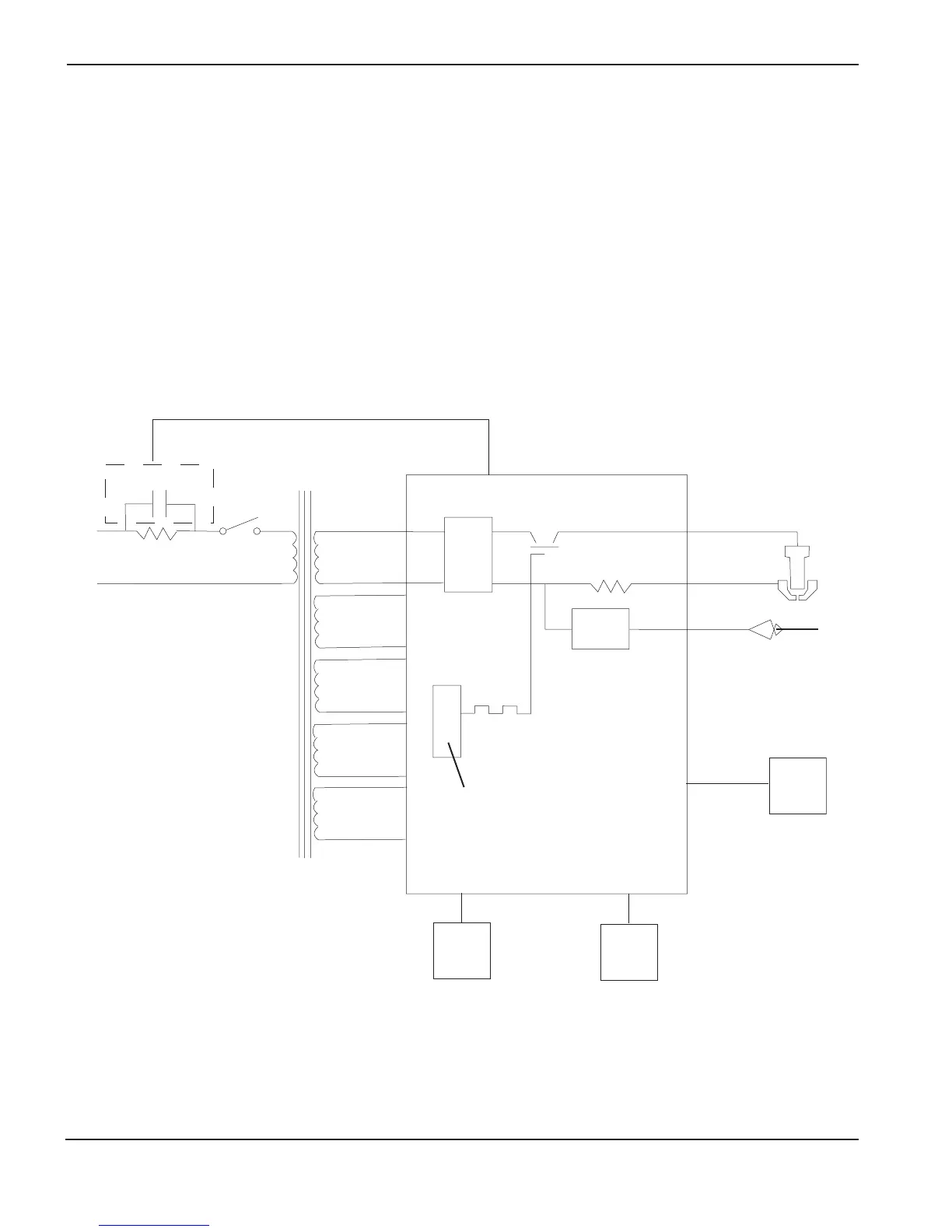

Theory of Operation

AC power enters the system through inrush resistor R1 into switch S1 then into the main transformer. The main

transformer T1 supplies voltage to the control circuitry and to the chopper module. The inrush contactor CR2 is

closed by the control circuitry on the power board PC1.

The chopper is incorporated into the power board PC1. The chopper consists of an isolated gate bipolar transistor

(IGBT). The IGBT is controlled by a pulse width modulated signal, set internally in the control circuitry on PC1.

The control circuitry regulates the output current, the air compressor, and the safety circuits. The output current is

set internally in the control circuitry to 12 amps. The air compressor operates during preflow, cutting, and post flow

modes. The compressor unit is set to output 40 psi (2.8 bar). The safety circuits consist of the cap sensor switch,

over voltage protection, and over temperature protection.

Work

Pilot Arc

Nozzle

Electrode

Cap

Sense

Over

Temp.

Air

Comp.

Current

Sense

Bridge

Pulse-width

modulator circuit

IGBT

T1

PC1

AC

in

S1R1

CR2

Powermax190c Block DIagram

Loading...

Loading...