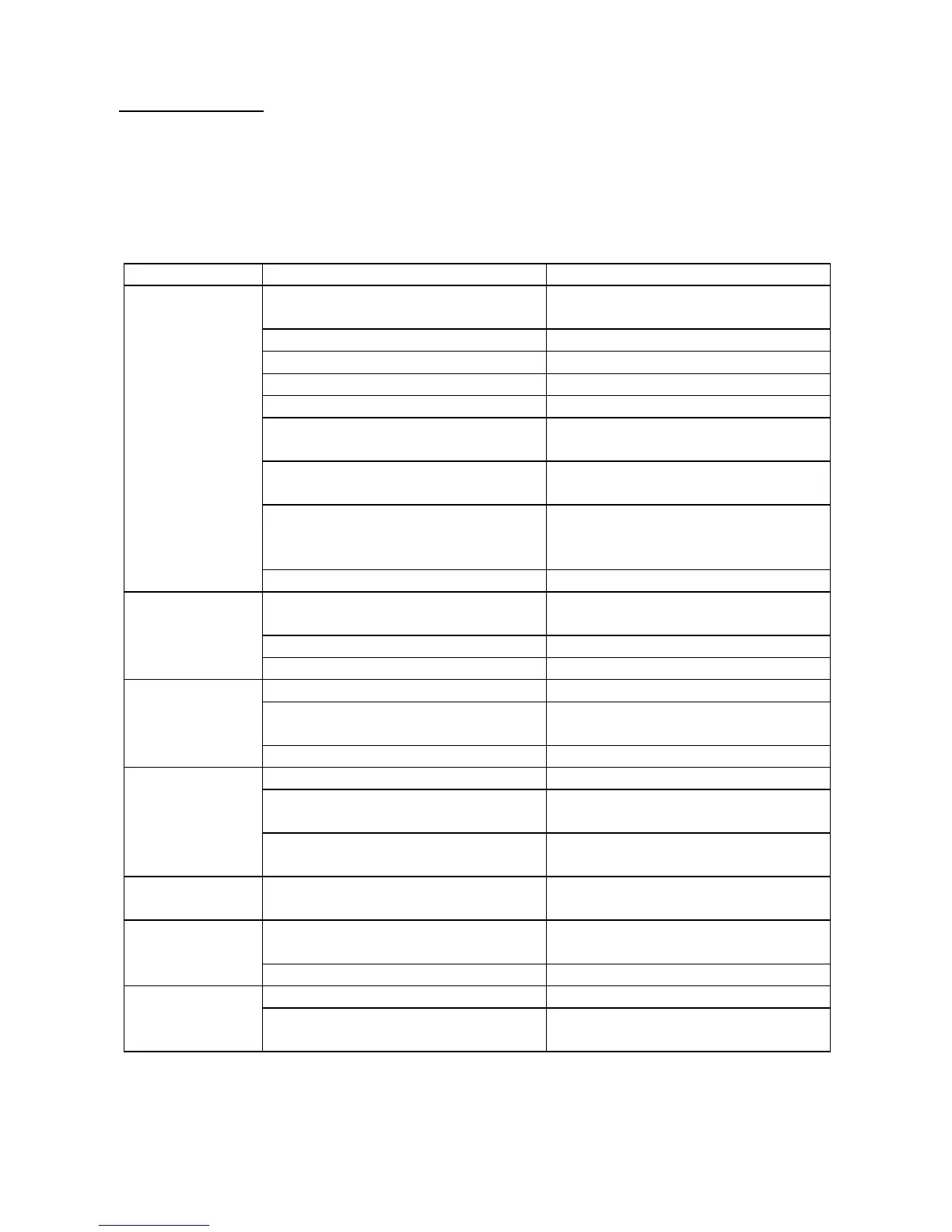

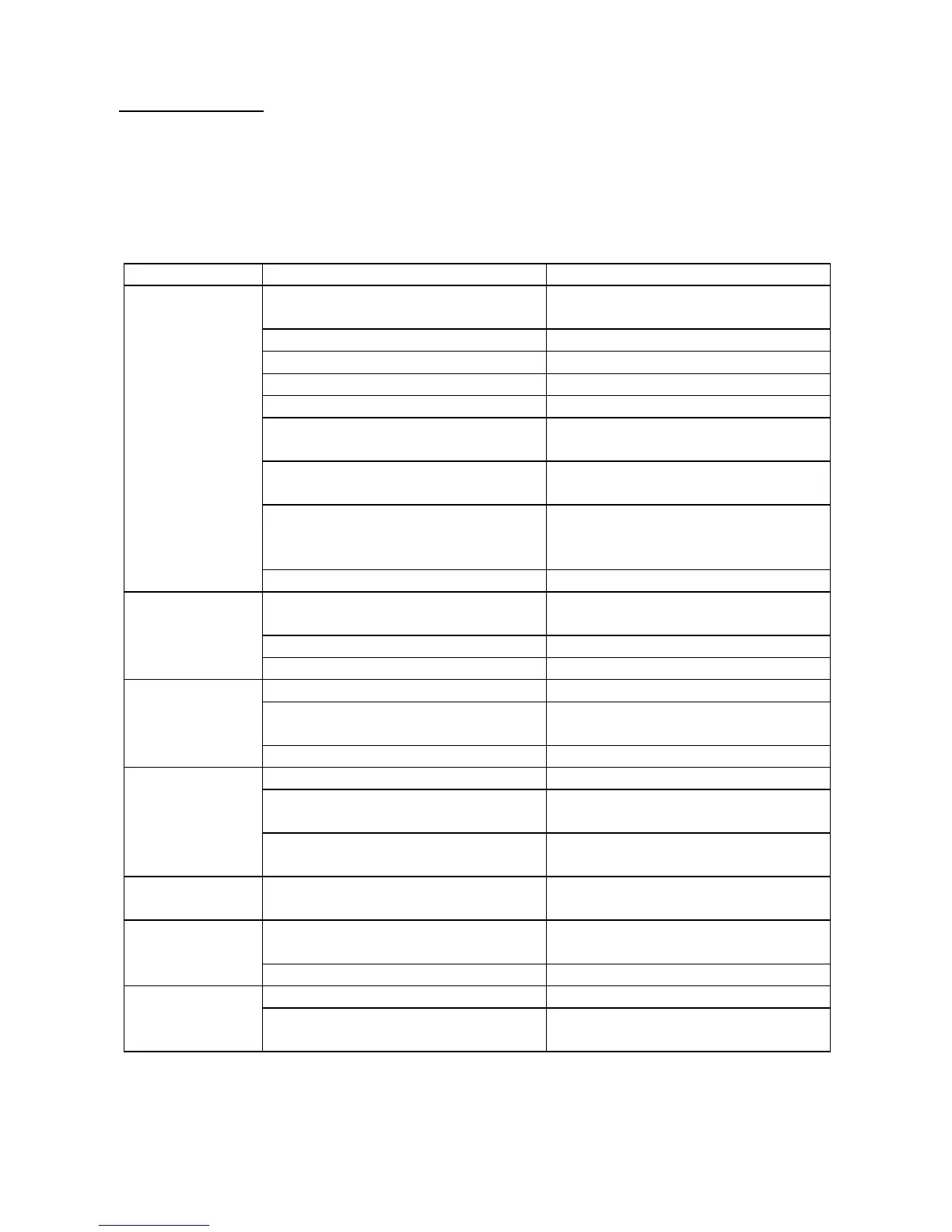

6. TROUBLESHOOTING.

6.1. Engine Troubleshooting - N.B. Where necessary all corrective actions should be carried out by

suitably qualified person/s.

6.2. If the starter rope becomes disconnected from the rope guide on handle, disconnect the spark plug

cap. Depress the blade control handle and pull the starter rope out from engine slowly and re-

engage in guide. Re connect spark plug cap.

Throttle lever not in the correct

position for the prevailing conditions.

Move throttle lever to correct

position.

Drain carburetor float bowl.

Air filter element is dirty.

Clean air filter element.

Tighten spark plug to 25- 30Nm.

Spark plug cap loose or disconnected

from plug.

Make sure spark plug cap is correctly

fitted onto spark plug.

Spark plug gap is incorrect.

Set gap between electrodes at

0.7 to 0.8mm.

Carburetor is flooded with fuel.

Remove air filter element and pull

starter rope continuously until

carburetor clears.

Contact the service dealer.

Engine difficult

to start or loses

power.

Dirt, water or stale fuel in tank.

Drain fuel and clean tank. Fill tank

with clean, fresh fuel.

Vent hole in fuel tank cap is plugged.

Clean or replace fuel tank cap.

Air filter element is dirty.

Clean air filter element.

Engine operates

erratically.

Fit new, correctly gapped plug.

Spark plug gap is incorrect.

Set gap between electrodes at

0.7 to 0.8mm.

Air filter element is dirty.

Clean air filter element.

Air filter element is dirty.

Clean air filter element.

Air slots in engine shroud are

blocked.

Remove debris from slots.

Cooling fins and air passages under

engine housing are blocked

Remove debris from cooling fins and

air passages.

Engine skips at

high speed.

Gap between electrodes of spark

plug is too close.

Set gap between electrodes at

0.7 to 0.8mm.

Cooling airflow is restricted.

Remove any debris from slots in

shroud, blower housing, air passages.

Mower vibrates

abnormally.

Cutting assembly is loose.

Blade/Cutting assembly is

unbalanced.

Loading...

Loading...