1-7

INSTALLATION

HC SERIES BOILERS HC 13-50, HC 23-84, HC 29-106, HC 33-124, HC 20-125, HC 33-160

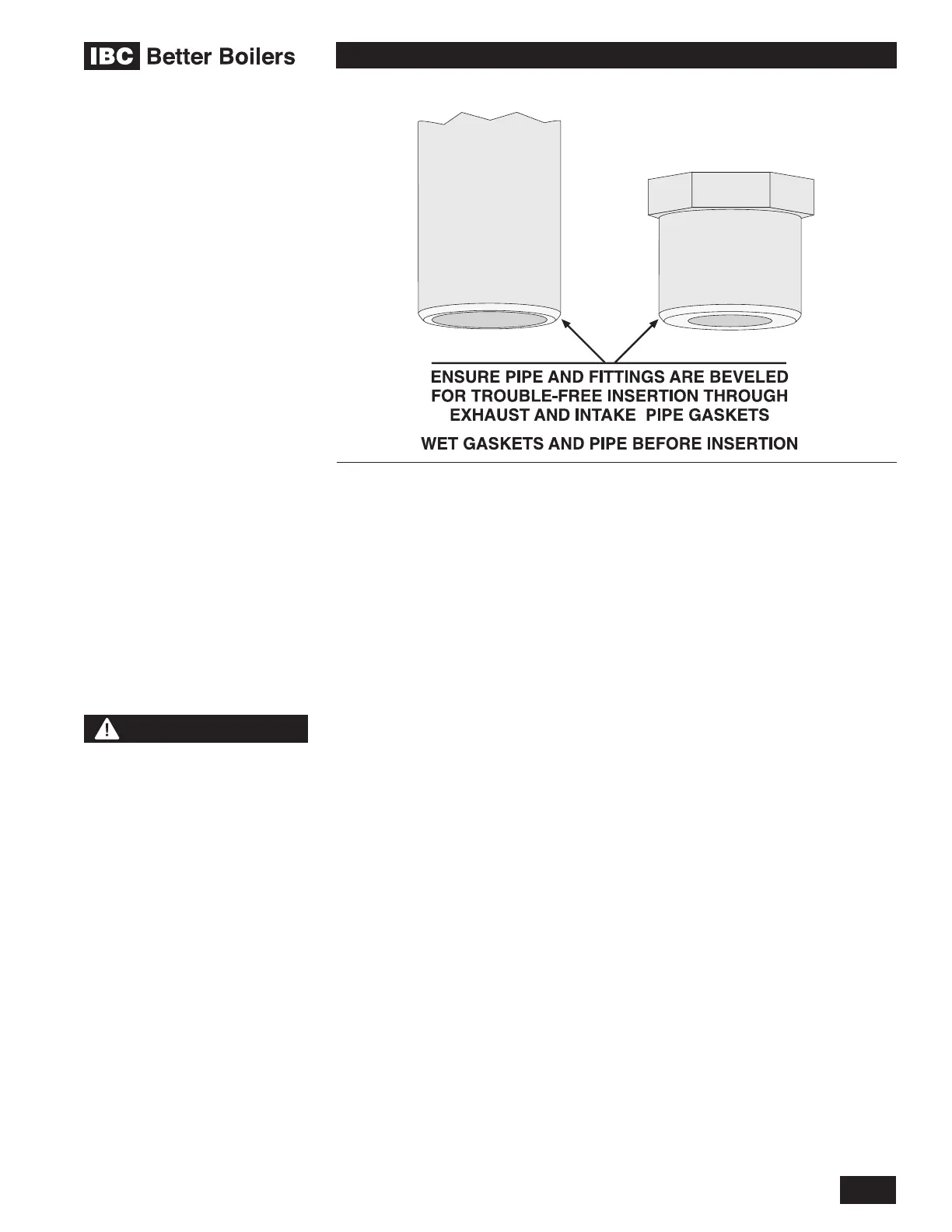

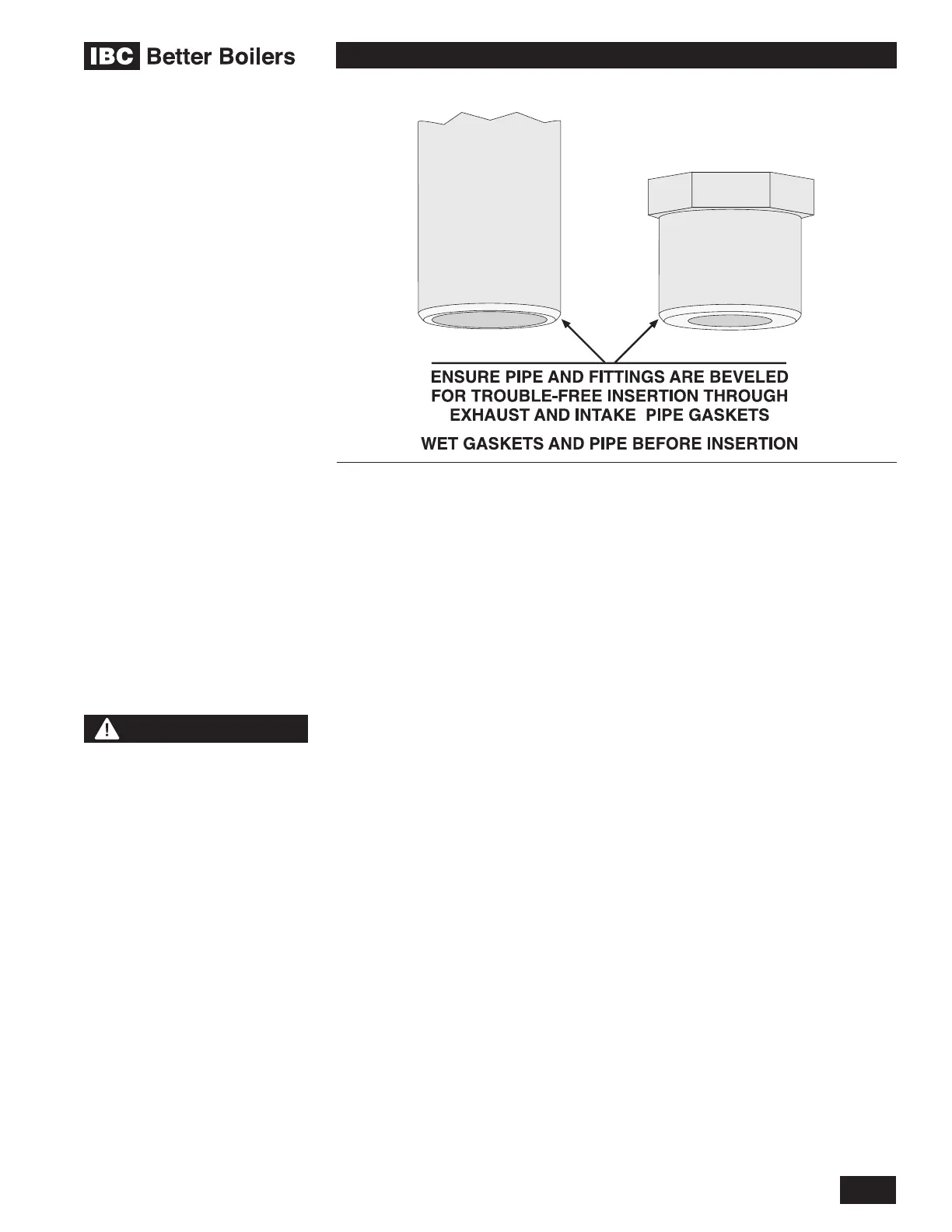

Exhaust piping is inserted directly into the 3" female stainless steel tting on the

top, left side of the boiler and run horizontally or vertically to the outdoors. Bird

screen of 1/4" stainless steel or plastic mesh eg. (IPEX System 636 drain grate

for CPVC systems) is useful to guard against foreign objects.

Follow all installation instructions supplied by the pipe and tting

manufacturer.

Ensure all venting components are clean of burrs/debris prior to assembly.

Care is to be taken to avoid ingestion into the fan of PVC/ABS debris left in the

combustion air piping.

All joints must be secured using appropriate solvent cement to bond the

respective pipe material (Canada: CPVC cement approved under ULC-S636,

in accordance with its manufacturer instructions; USA: PVC (ASTM D2564),

or PVC/ABS (D2235) - Use transition glue anywhere that PVC and CPVC are

joined. Follow the cement manufacturer’s instructions closely when joining

various components. For PPs, connections shall be secured using approved

retainer clips supplied by the respective PPs manufacturer.

All vent connections must be liquid and pressure tight. Prior to ring the boiler,

and before any of the venting run is concealed by the building construction, the

installer must test the exhaust joints under fan pressure with the vent blocked,

using a soap/water solution. Installer must ll condensate trap prior to test.

1.4.4 Venting Passage Through Ceiling and Floor

• Conrm material meets local codes including re stopping requirements.

• Some local jurisdictions require a minimum initial length of pipe be exposed or

accessible for inspection.

• Pipe clearances - no IBC requirements, but best practice allows a minimum

1/4" gap around the pipe to prevent binding and expansion noise; follow local

codes.

• All piping must be liquid and pressure tight.

BEST PRACTICES

To reduce the possibility of

expansion noise, allow a 1/4"

gap around the exhaust and

air intake piping.

Figure 4

Loading...

Loading...