Page 9

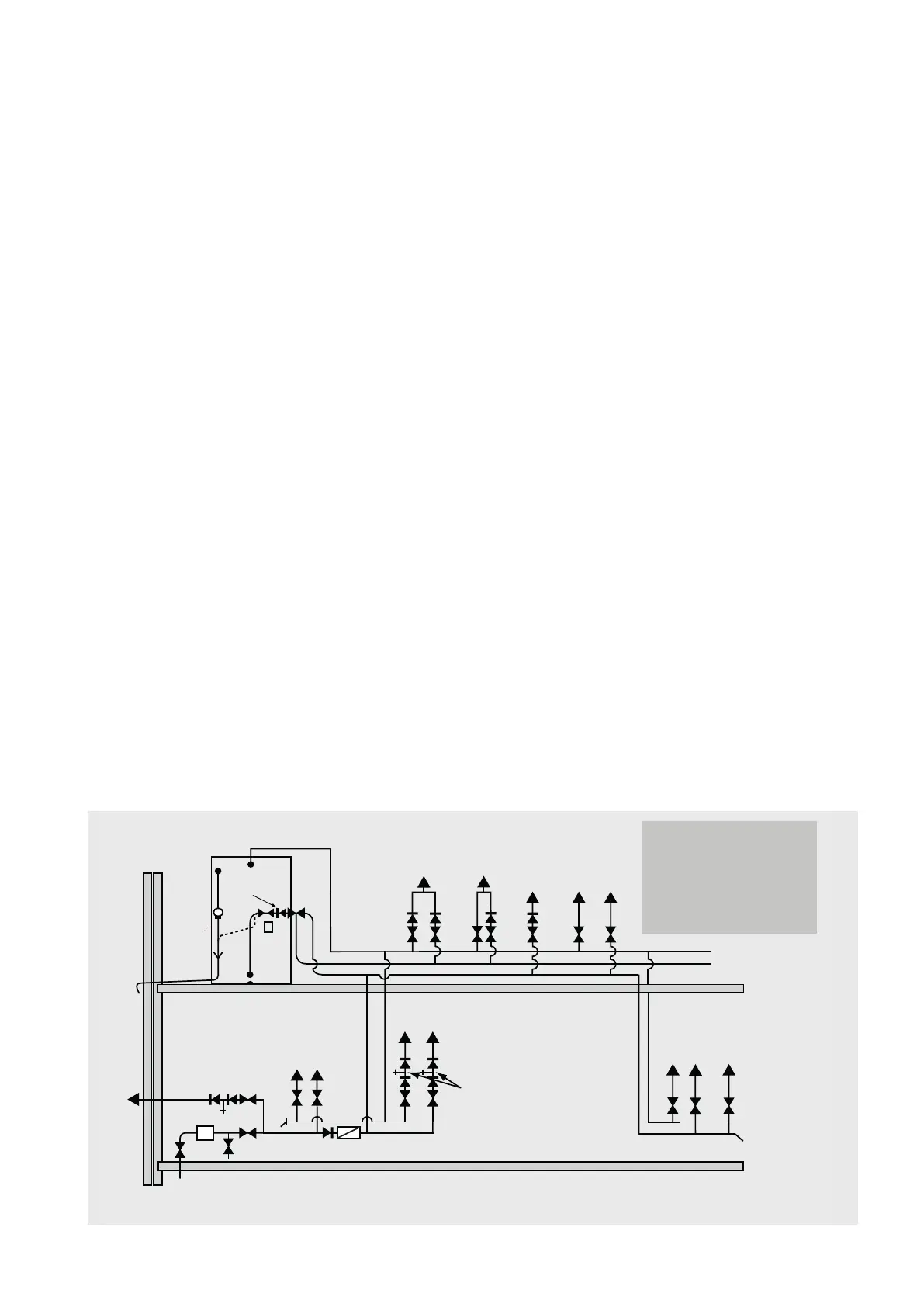

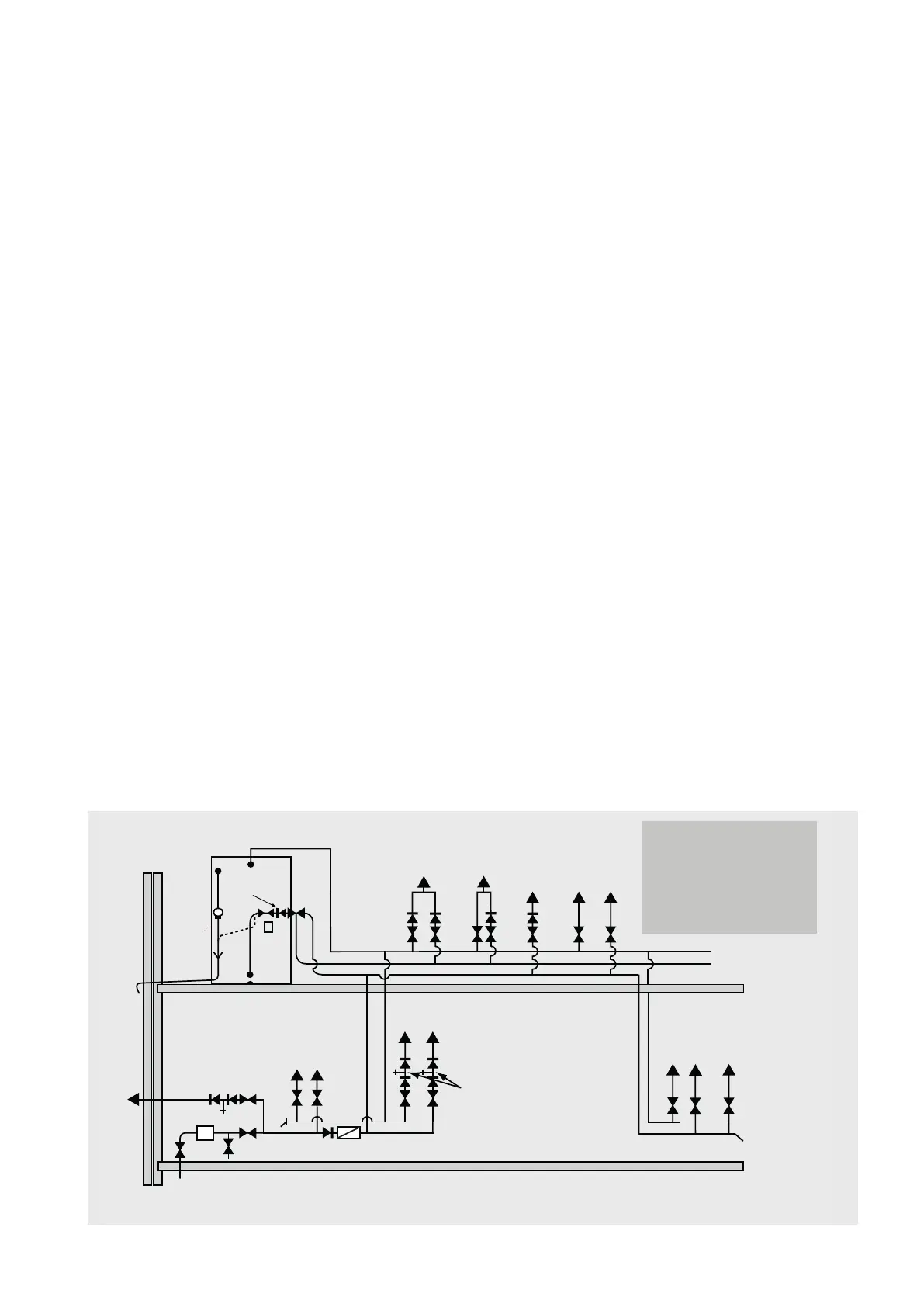

INCOMING COLD SUPPLY

M

DC

DC

DC

TO

EXTERNAL

TAP

SINK

WATER SOFTENER (IF NECESSARY)

WM or DWM

WHB

W.C.

DC

DC

SH

DHW

WHB

WC BATH

SCV

SCV

P&T

ERV/NRV

PRV

DCV

Note:

Cold supplies to single taps must be

taken from the mains cold water

system.

Cold supplies to mixer taps must be

taken from the balanced cold water

connection on the combination

valve.

General Restrictions

a. The highest hot or cold water draw o point should not exceed 10 metres above

the Pressure Reducing Valve.

b. An ascending spray type bidet or any other appliance with a Class 1 back-syphonage

risk requiring a type A air gap should not be used.

c. Ideal Pro should not be used where steam is the primary heating medium, or in a

situation where maintenance is likely to be neglected.

d. Unvented cylinders are not suitable for use with solid fuel boilers.

e. If the supply to the mixer ttings (other than a dual outlet type) is not taken from

the balanced supply the system will become over pressurized and cause the

pressure relief valve to discharge. Over time this could also cause the premature

failure of the appliance itself which will not be covered by the warranty.

f. In larger properties with a number of bathrooms/en-suites and long pipe runs

we would recommend that the balance cold supply is provided with its own

pressure reducing valve and is not taken from the balanced cold connection on

the combination valve. In this case it will also be necessary to t a small expansion

vessel on the balanced cold water system to accommodate the pressure rise caused

by the increase in temperature of the balanced cold water.

g. Check the performance requirements of the terminal ttings with regard to ow/

pressure are suitable.

h. In relation to potable water systems, expansion vessels shall be installed in a vertical

orientation and located so that the length of the connecting pipe work is kept to

a minimum.

Shower Fittings

Aerated taps are recommended to prevent splashing. Any type of shower mixing valve

can be used as long as both the hot and cold supplies are mains fed. However, all mains

pressure systems are subject to dynamic changes particularly when other hot and cold

taps/showers are opened and closed, which will cause changes in the water temperature

at mixed water outlets such as showers. For this reason and because these are now no

more expensive than a manual shower we strongly recommend the use of thermostatic

showers with this appliance. These must be used in 3 storey properties where the

impact on pressure/temperature of opening another tap in the system is greater than

normal. The shower head provided must also be suitable for mains pressure supplies.

Pipe Layout

In all mains pressure installations it is important

to remember that the incoming cold supply

must be shared between all terminal ttings. It

is important that a 22mm supply is brought to

the appliance and a 22mm take-o is continued

at least to the bath. If there are two baths, 28mm

pipework should be considered. One metre of

smaller diameter pipework, or ow restrictors,

should be provided on the nal connection to

all outlets so as to balance the water available.

In any event the distribution pipework should

generally be in accordance with BS EN806-1 to 5.

Plastic Pipework

This appliance is suitable for use with plastic

pipework as long as the material is recommended

for the purpose by the manufacturer and is installed

fully in accordance with their recommendations.

Secondary Hot Water Circulation

All models 210 litres and above are tted with

a secondary return tapping as standard (see

tables 1 and 2 for details). If tted, an extra

expansion vessel may be necessary. A non-

return valve MUST be FITTED near the return

connection. No valve or terminal tting should

be installed between the non return valve and

the cylinder. (See schematic arrangement on

page 15.) All pipes kept hot by the secondary

circulation should be insulated.

INSTALLATION

INSTALLATION

Loading...

Loading...