102

END Lo END Hi=CR (0x0D), END Lo=LF (0x0A)

7.2.3.1 ASCII mode check (LRC Check)

Check code (LRC Check) is the value combined of address and data content result. For instance, the check

code of above 2.2.2 communication message is: 0x02+0x06+0x00+0x08+0x13+0x88=0xAB, then take the

compliment of 2=0x55. Below is a simple LRC calculation function for user reference (programed with C

language):

Static unsigned char

LRC(auchMsg,usDataLen)

unsigned char *auchMsg;

unsigned short usDataLen;

{

unsigned char uchLRC=0;

while(usDataLen--)

uchLRC+=*auchMsg++;

return((unsigned char)(~((char)uchLRC)));

}

7.3 Command code and communication data illustration

7.3.1 RTU mode

7.3.1.1 Command code:03H

03H(correspond to binary 0000 0011),read N words(Word)(the Max. continuous reading is 16 words)

Command code 03H means that if the master read data from the inverter, the reading number depends on

the “data number” in the command code. The Max. Continuous reading number is 16 and the parameter

address should be continuous. The byte length of every data is 2 (one word). The following command format

is illustrated by hex (a number with “H” means hex) and one hex occupies one byte.

The command code is used to read the working stage of the inverter.

For example, read continuous 2 data content from0004H from the inverter with the address of 01H (read the

content of data address of 0004H and 0005H), the frame structure is as below:

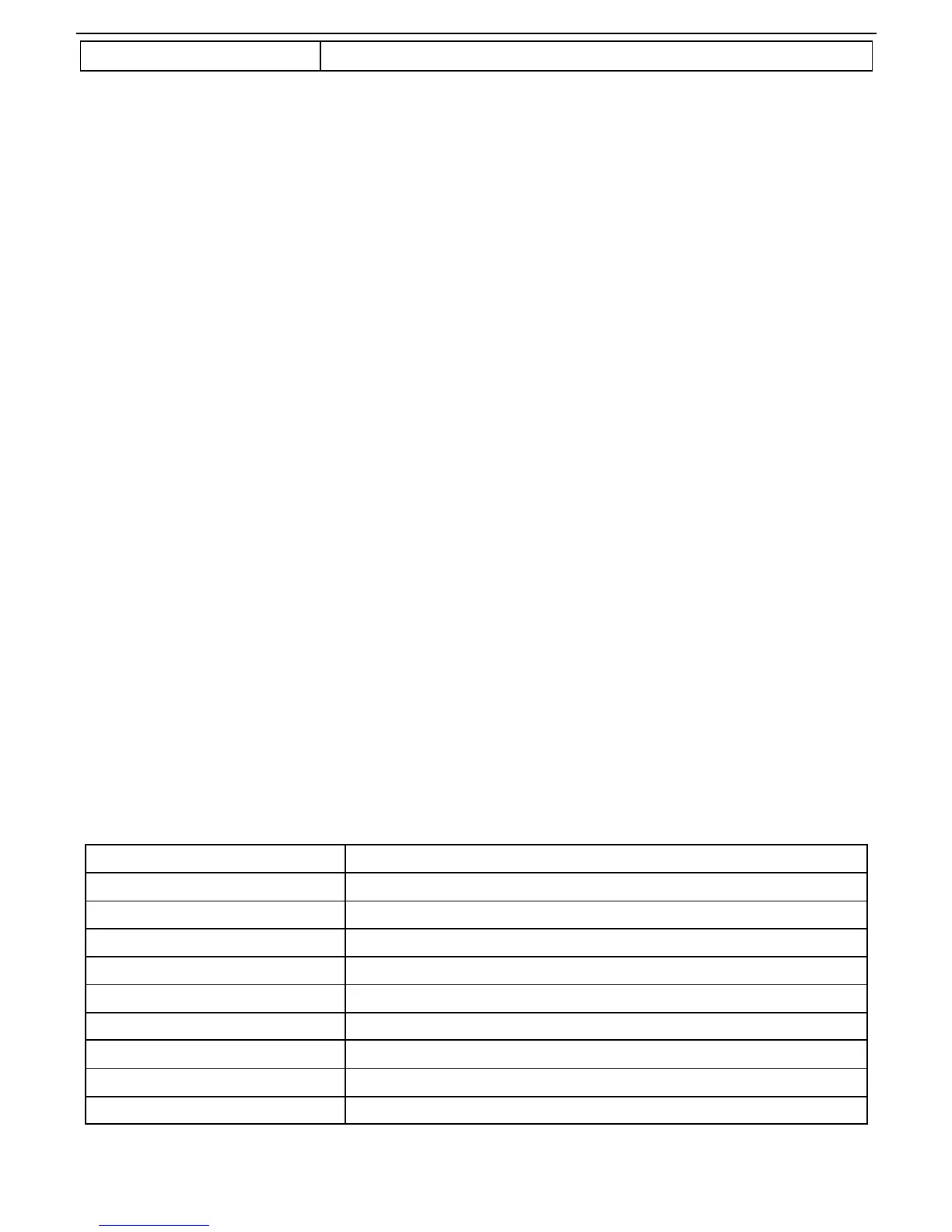

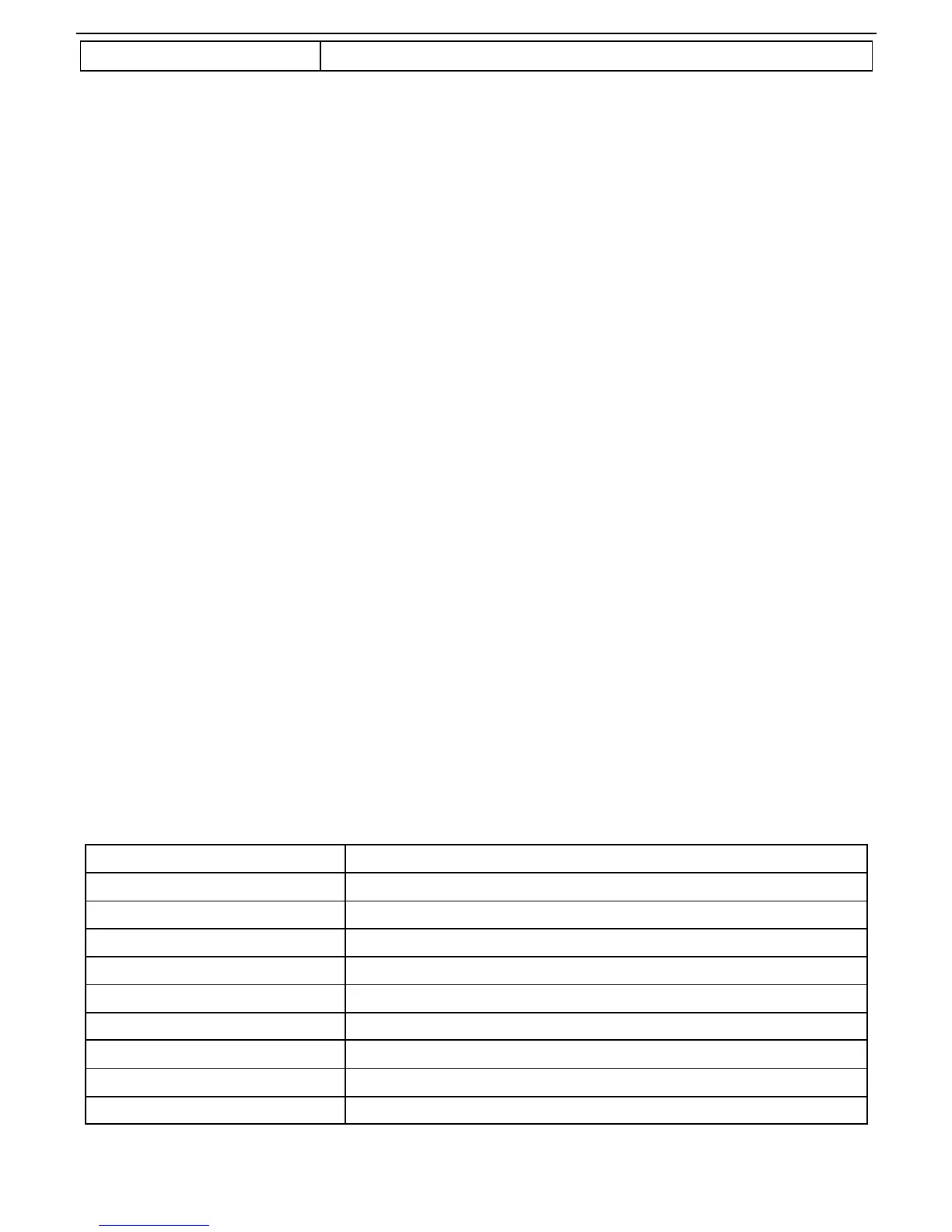

RTU master command message (from the master to the inverter)

START T1-T2-T3-T4

ADDR 01H

CMD 03H

High bit of the start address 00H

Low bit of the start address 04H

High bit of data number 00H

Low bit of data number 02H

CRC low bit 85H

CRC high bit CAH

END T1-T2-T3-T4

T1-T2-T3-T4 between START and END is to provide at least the time of 3.5 bytes as the leisure time and

Loading...

Loading...