2

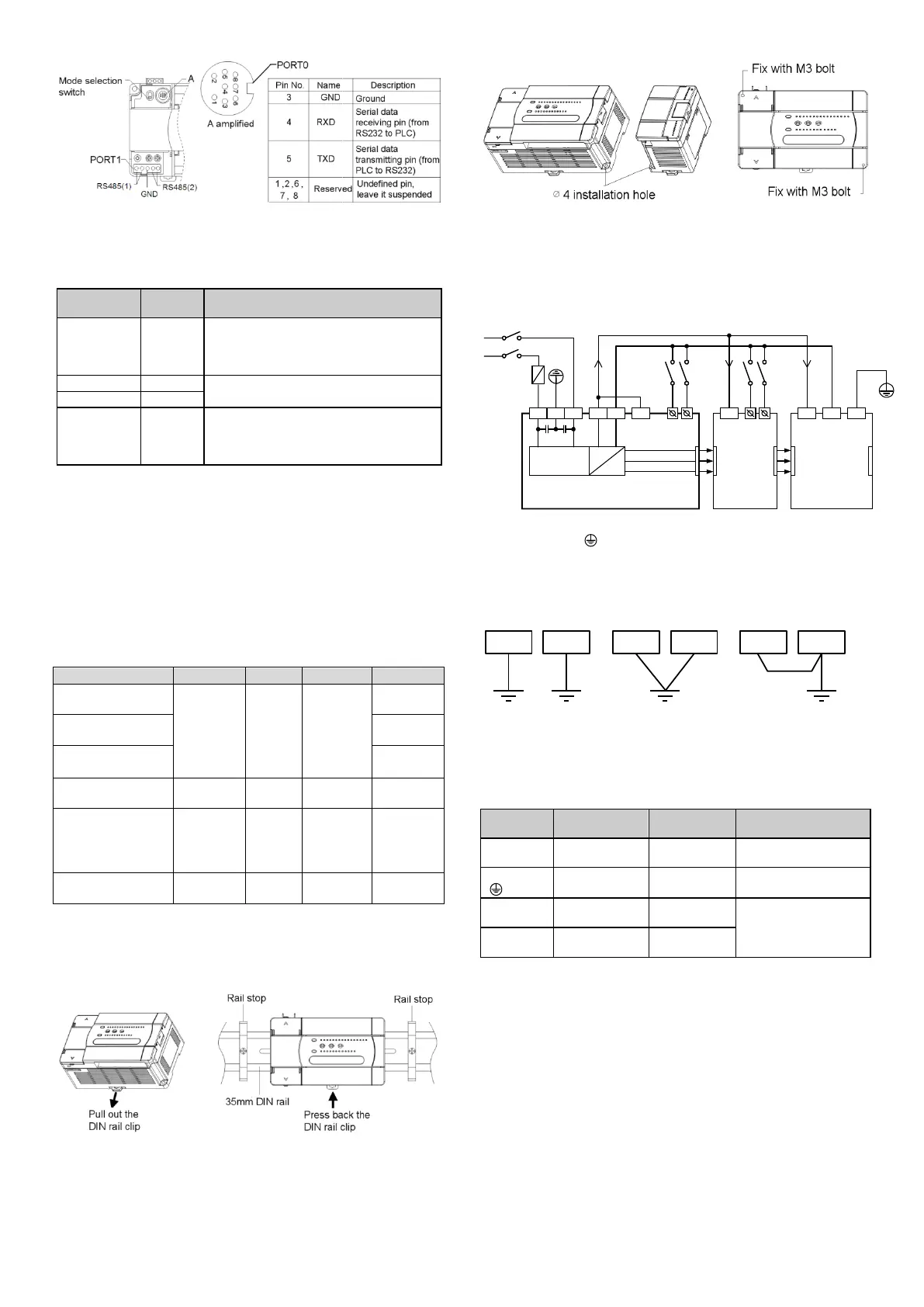

As a terminal dedicated to user programming, PORT0 can be

converted to programming protocol through the mode selection switch.

The relationship between PLC operation status and the protocol used

by PORT0 is shown in the following table.

Mode selection

switch position

Programming protocol, or Modbus protocol,

or free-port protocol, or N: N network

protocol, as determined by user program and

system configuration

Converted to programming protocol

If the system configuration of user program is

free-port protocol, it converts to programming

protocol automatically after stop; or system

protocol keeps unchanged

PORT1、PORT2 are ideal for connection with equipment that can

communicate (such as inverters). With Modbus protocol or RS485

terminal free protocol, it can control multiple devices through the

network. Its terminals are fixed with screws. You can use a shielded

twisted-pair as the signal cable to connect communication ports by

yourself.

5 Installation

PLC is applicable to Installation category II, Pollution degree 2.

5.1 Installation Dimensions

IVC1L-0806MAR

、

IVC1L-0806MAT

IVC1L-1208MAR

、

IVC1L-1208MAT

IVC1L-1410MAR

、

IVC1L-1410MAT

、

IVC1L-1614MAR

、

IVC1L-1614MAT

IVC1L-2416MAR

、

IVC1L-2416MAT

、

IVC1L-1614MAR1

、

IVC1L-1614MAT1

、

IVC1L-3624MAR

、

IVC1L-3624MAT

5.2 Installation Method

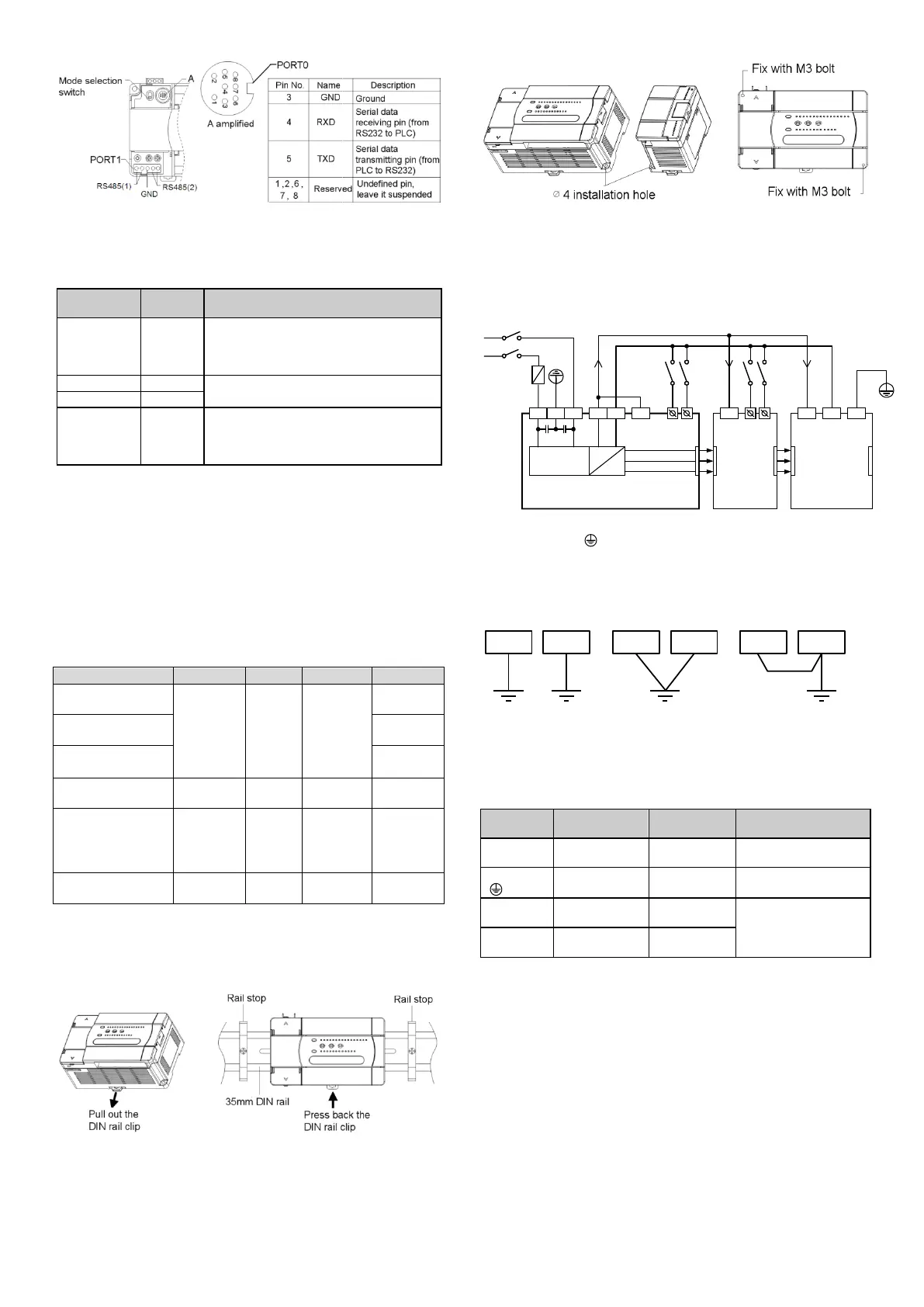

DIN rail mounting

Generally you can mount the PLC onto a 35mm-wide rail (DIN), as

shown in the following figure.

Screw fixing

Fixing the PLC with screws can stand greater shock than DIN rail

mounting. Use M3 screws through the mounting holes on PLC

enclosure to fix the PLC onto the backboard of the electric cabinet, as

shown in the following figure.

5.3 Cable Connection And Specification

Connecting power cable and grounding cable

The connection of AC power and auxiliary power is demonstrated in the

following figure.

We suggest you wire a protection circuit at the power supply input

terminal.See the figure below.

Connect the PLC terminal to the grounding electrode. To ensure

reliable grounding cable connection, which makes the equipment safer

and protects it from EMI.use AWG12~16 cable, and make the cable as

short as possible. Use independent grounding. Avoid sharing route with

the grounding cable of other equipment (particularly those with strong

EMI). See the following figure.

Cable specification

When wiring a PLC, use multi-strand copper wire and ready-made

insulated terminals to ensure the quality. The recommended model and

the cross-sectional area of the cable are shown in the following table.

Cable lug and

heat-shrink tube

H1.5/14 round insulated

lug, or tinned cable lug

H2.0/14 round insulated

lug, or tinned cable end

UT1-3 or OT1-3

solderless lug

Φ3 or Φ

4

heat shrinkable

tube

Fix the prepared cable head onto the PLC terminals with screws.

Fastening torque: 0.5~0.8Nm.

The recommended cable processing-method is shown in the following

figure.

PLC PLC

Other

equipment

Other

equipment

PLC

Other

equipment

Best Good

Bad

Loading...

Loading...