01 - Machine

03 - Safety

27 - Maintenance Positions

01 - 14 9813/5150-2 01 - 14

27 - Maintenance Positions

Introduction .................................................... 01-14

Health and Safety .......................................... 01-19

Introduction

For: 225 [T3 GE0], 225 [T4F GE0], 225T [T3

GE0], 225T [T4F GE0], 260 [T3 GE0], 260

[T4F GE0], 260T [T3 GE0], 260T [T4F GE0],

280 [T3 GE0], 280 [T4F GE0], 300 [T3 GE0],

300 [T4F GE0], 300T [T3 GE0], 300T [T4F

GE0], 320T [T3 GE0], 320T [T4F GE0], 330

[T3 GE0], 330 [T4F GE0] .......... Page 01-14

For: 225T [T3 GE0], 225T [T4F GE0], 260

[T3 GE0], 260 [T4F GE0], 260T [T3 GE0],

260T [T4F GE0], 280 [T3 GE0], 280 [T4F

GE0], 300 [T3 GE0], 300 [T4F GE0], 300T

[T3 GE0], 300T [T4F GE0], 320T [T3 GE0],

320T [T4F GE0], 325T [T4F GE0], 330 [T3

GE0], 330 [T4F GE0] ................ Page 01-16

(For: 225 [T3 GE0], 225 [T4F GE0], 225T

[T3 GE0], 225T [T4F GE0], 260 [T3 GE0],

260 [T4F GE0], 260T [T3 GE0], 260T [T4F

GE0], 280 [T3 GE0], 280 [T4F GE0], 300

[T3 GE0], 300 [T4F GE0], 300T [T3 GE0],

300T [T4F GE0], 320T [T3 GE0], 320T

[T4F GE0], 330 [T3 GE0], 330 [T4F GE0])

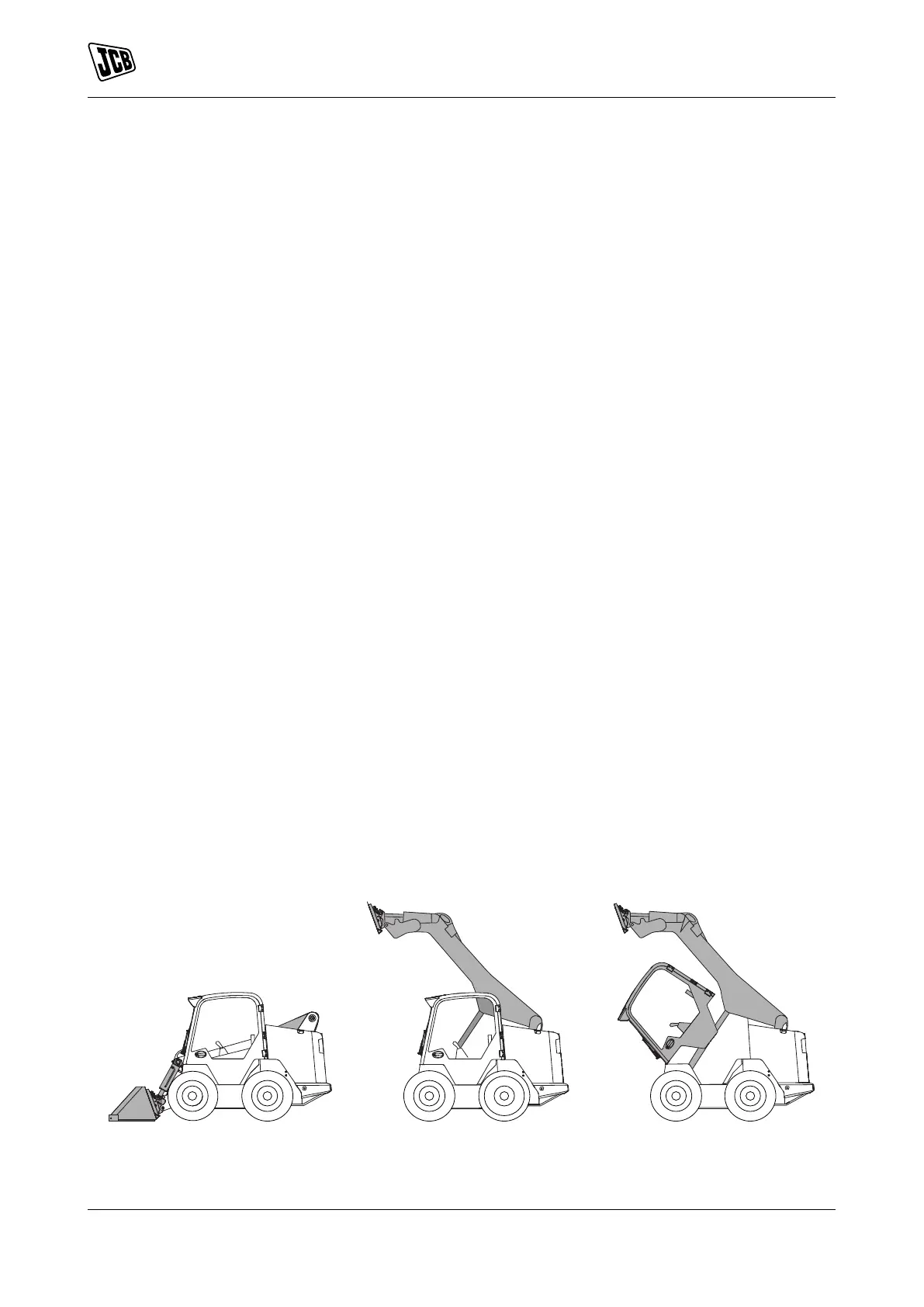

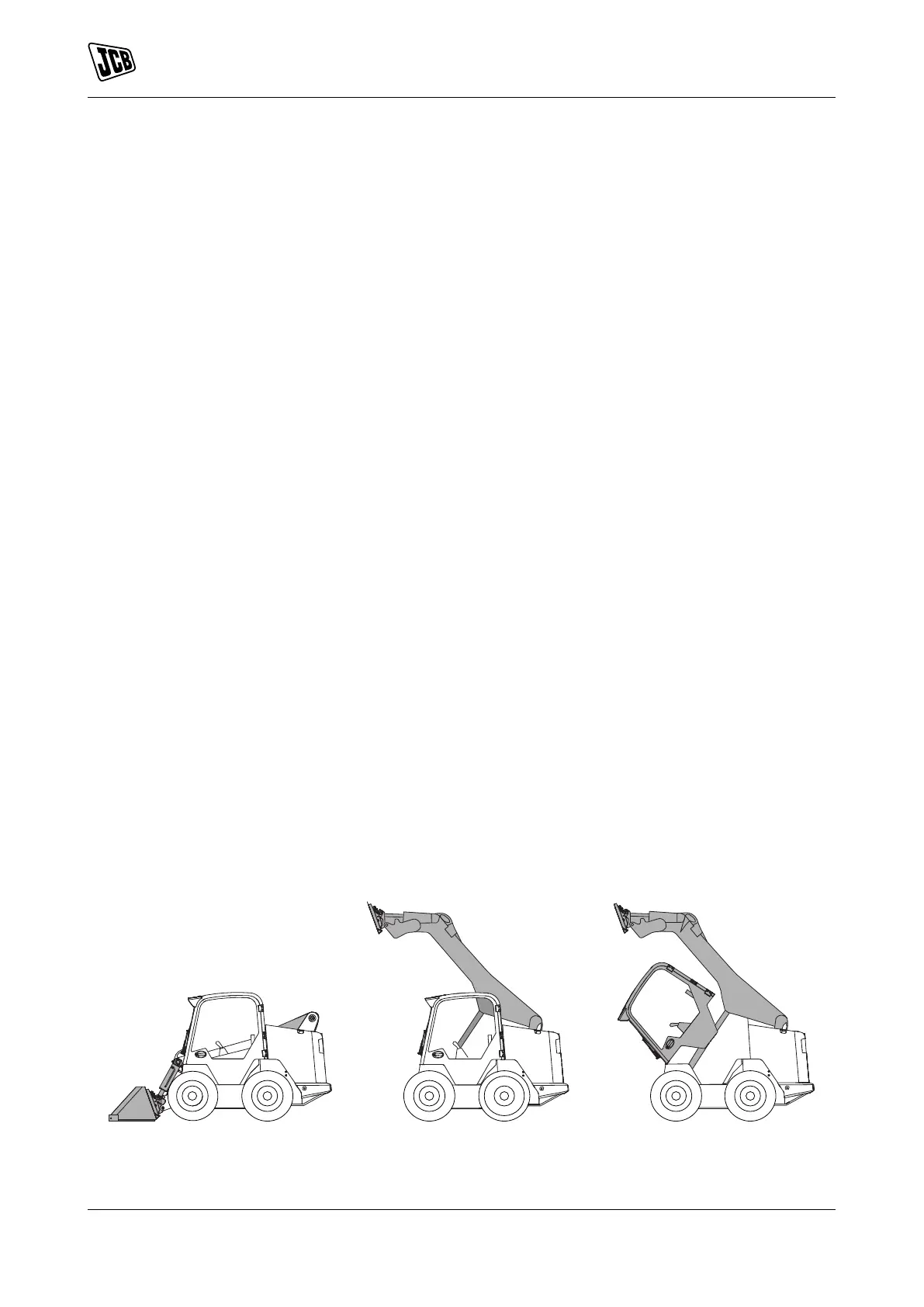

Make the machine safe before you start a

maintenance procedure. Refer to (PIL 01-03).

You can complete most of the maintenance

procedures with the lift arm lowered. Unless a

maintenance procedure instructs you differently, you

must lower the lift arm.

If you raise the lift arm to get access for maintenance,

you must install the maintenance strut on the lift arm.

If the cab is to be lifted to get access for

maintenance, you must raise the lift arm and install

the maintenance strut on the lift arm.

Release the hydraulic pressure. Refer to (PIL 30-00).

Figure 2.

A Lift arm lowered B Lift arm raised

C Lift arm and cab raised

Loading...

Loading...