Section 1 - General Information

Torque Settings

Hydraulic Connections

1-33 1-33

1-05-01 Issue 02

Procedure

Torque all of the O-Ring face seal fittings. Always make

sure that the correct torque is used to tighten the specific

fitting size. K

Table 12. ( T 1-34).

To prevent damage to the O-Ring during the assembly

procedure its important to use the double-spanner method

of tightening. K

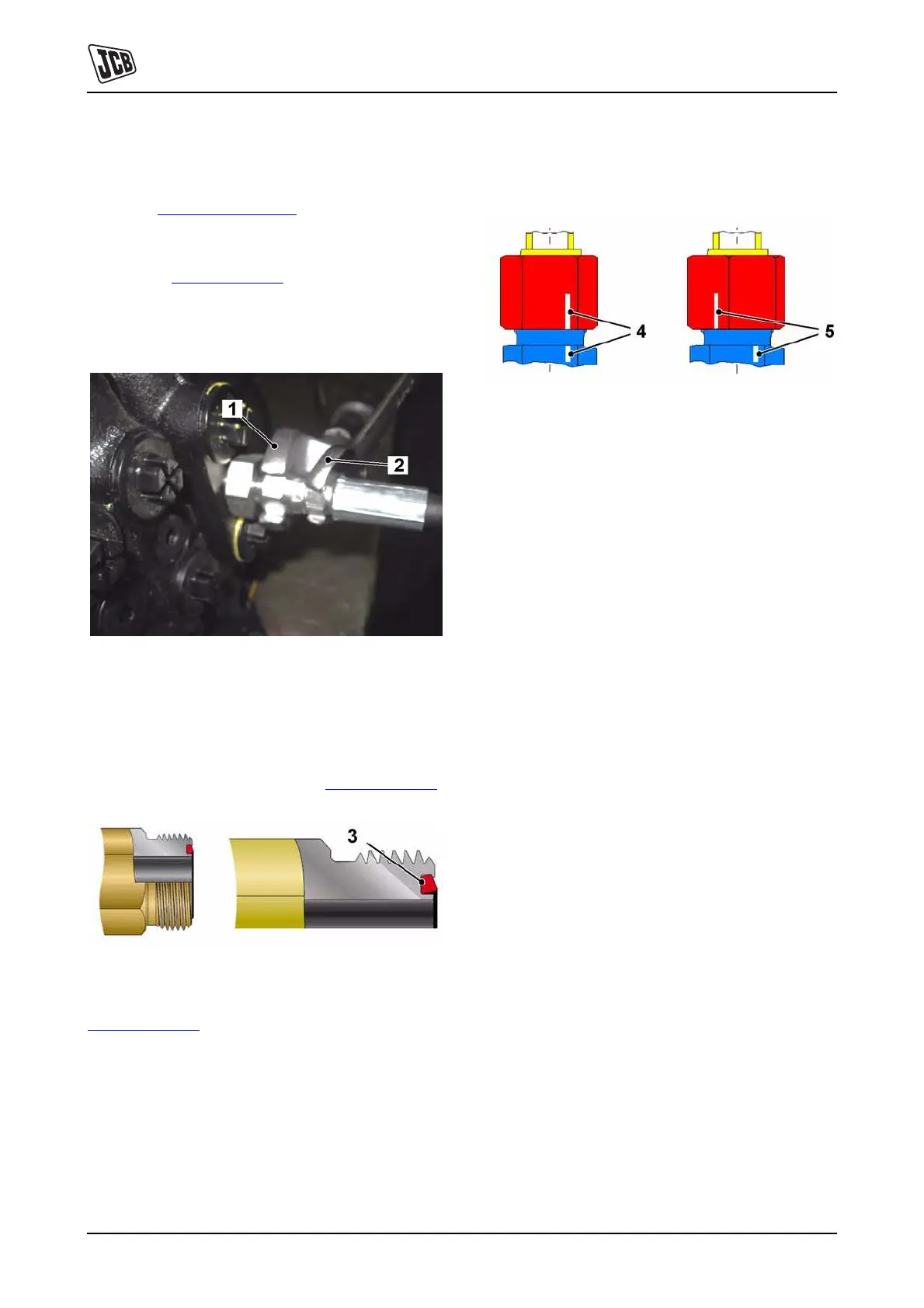

Fig 3. ( T 1-33).

– Torque spanner 1.

– Open ended/combination spanner.2.

T044470

Fig 3.

Key Points

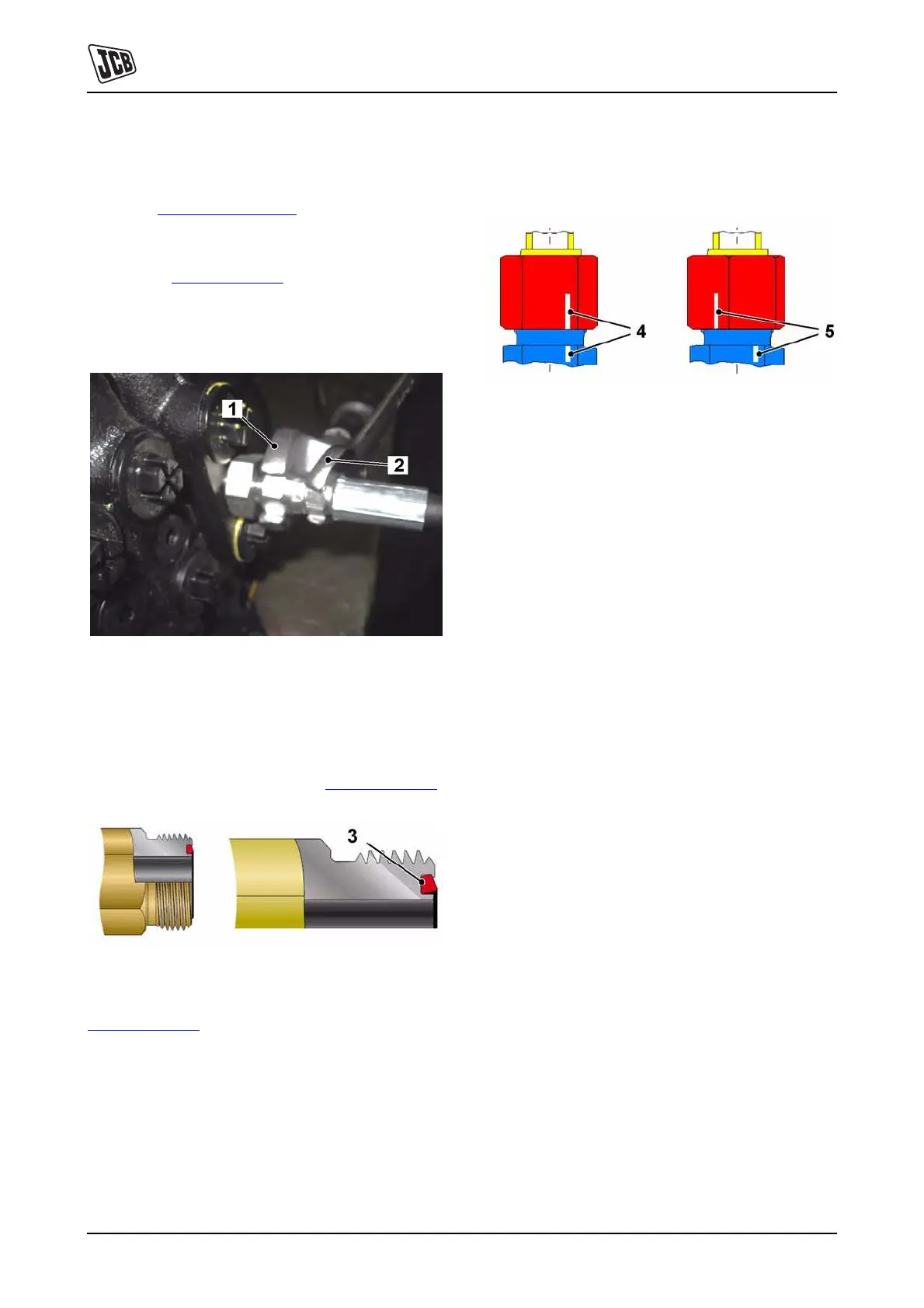

A rubber trapezoid O-Ring seal 3 is pre-installed in the

Captive O-Ring Groove (CORG). This groove is the half-

dovetail type and has very secure retention properties as

the seal is below the lip of the groove. K

Fig 4. ( T 1-33).

T044480

Fig 4.

Swivel-nut line marking, the broken-line method.

K

Fig 5. ( T 1-33).

– The swivel-nut is hand-tight 4.

– The swivel-nut is tightened to the correct torque

setting 5.

T044490

Fig 5.

Loading...

Loading...