Maintenance

Hydraulic System

72 9831/3200-3 72

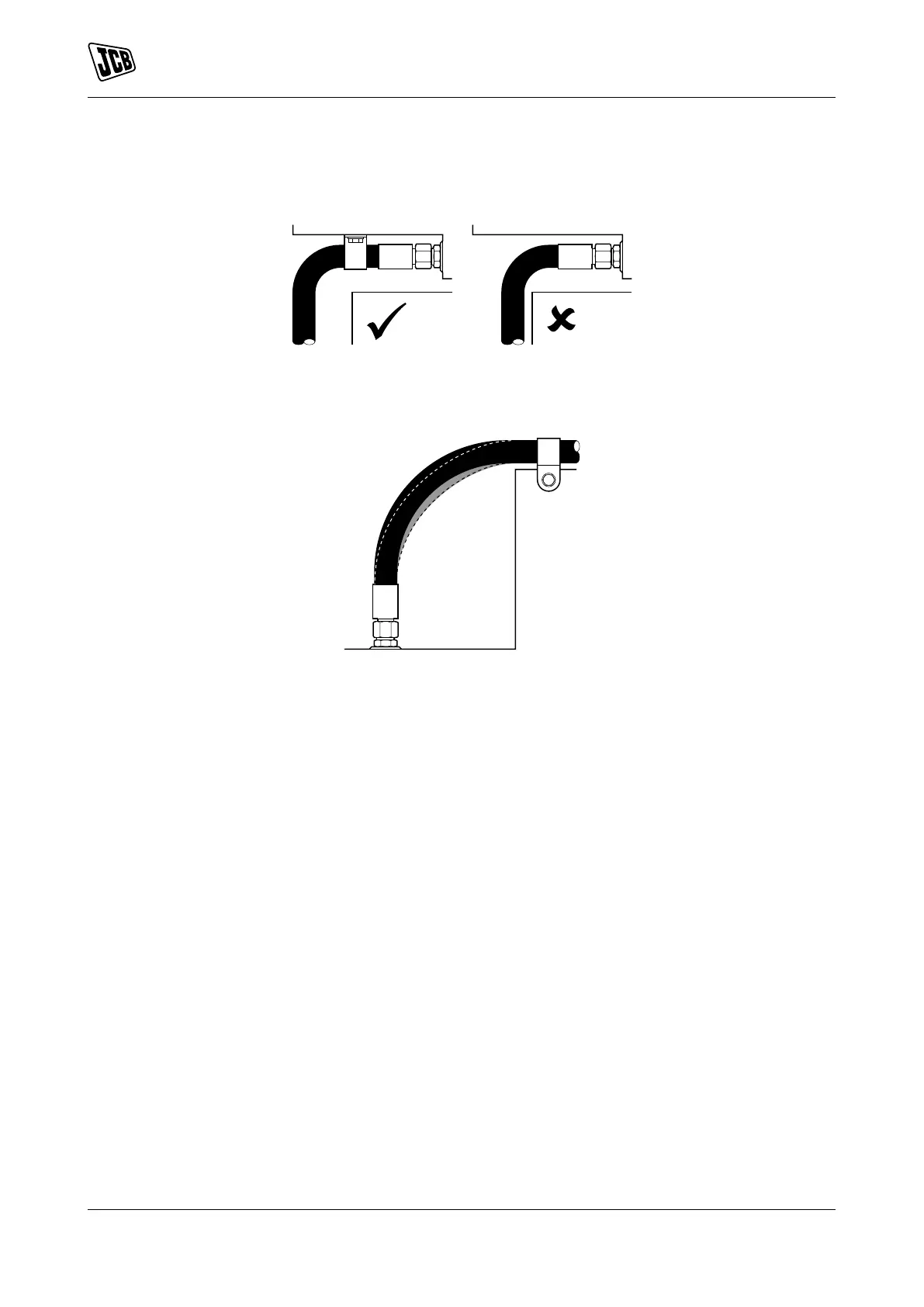

4.4. Use the hose clamps (where possible) to support long hose runs and keep the hoses away from

moving parts, etc.

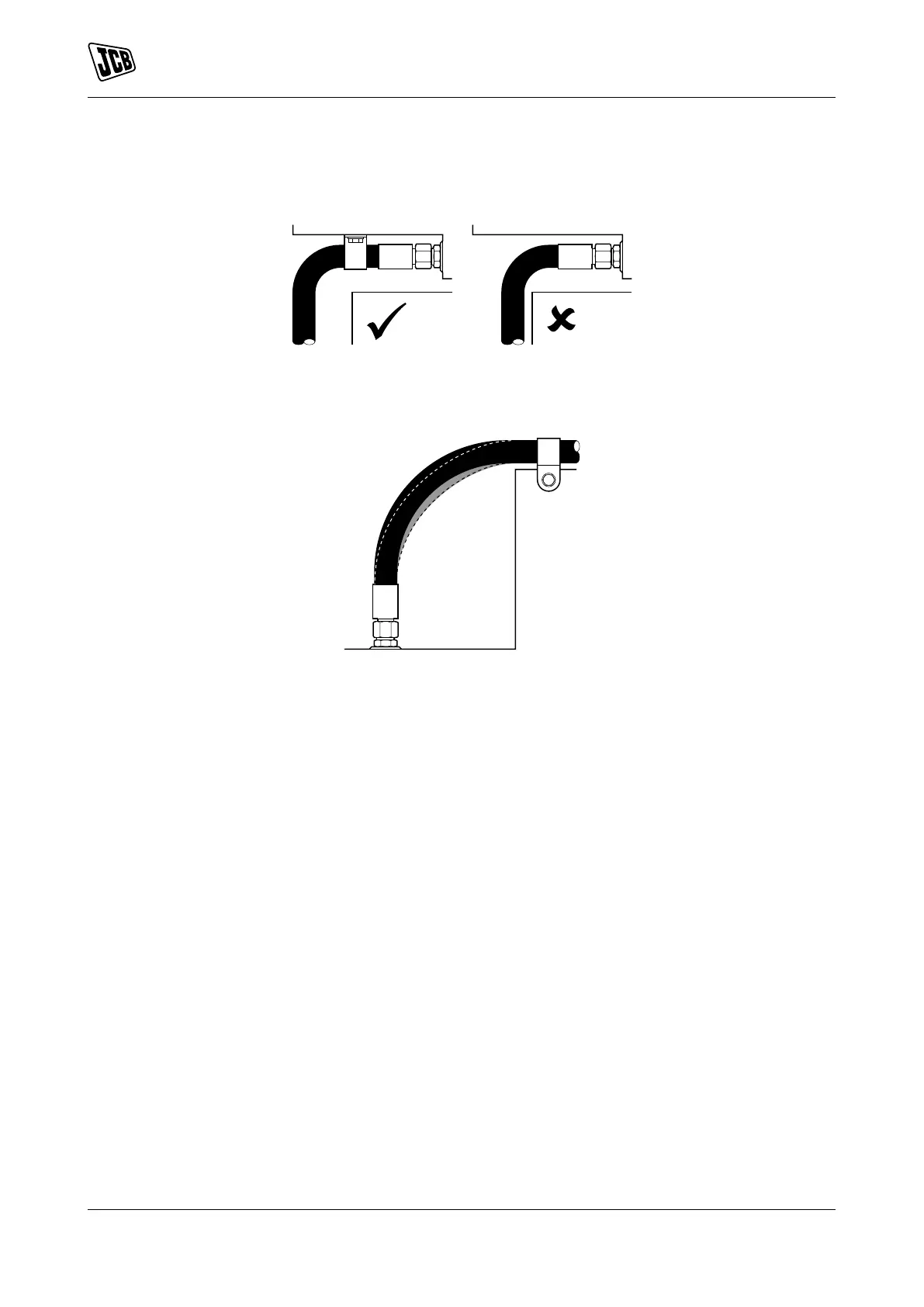

Figure 43.

4.5. To allow for length changes when the hose is pressurised, do not clamp at the bend. The curve absorbs

the change.

Figure 44.

5. Check for leaks:

5.1. Start the machine.

5.2. Operate the related controls to increase the pressure in the hydraulic system.

5.3. Stop the machine then remove the key.

5.4. Check for indications of leakage at the hose connections. Correct, as necessary.

Disconnecting the Hydraulic Hoses

1. Make the machine safe.

Refer to: Maintenance Positions (Page 58).

2. Vent the hydraulic system.

3. Disconnect the hoses.

4. Check the hoses and adaptors for damage.

5. If necessary, install the blanking caps.

6. Check for leaks:

6.1. Start the machine.

6.2. Operate the related controls to increase the pressure in the hydraulic system.

6.3. Stop the machine then remove the key.

6.4. Check for indications of leakage at the hose connections. Correct, as necessary.

Loading...

Loading...