19

Troubleshooting

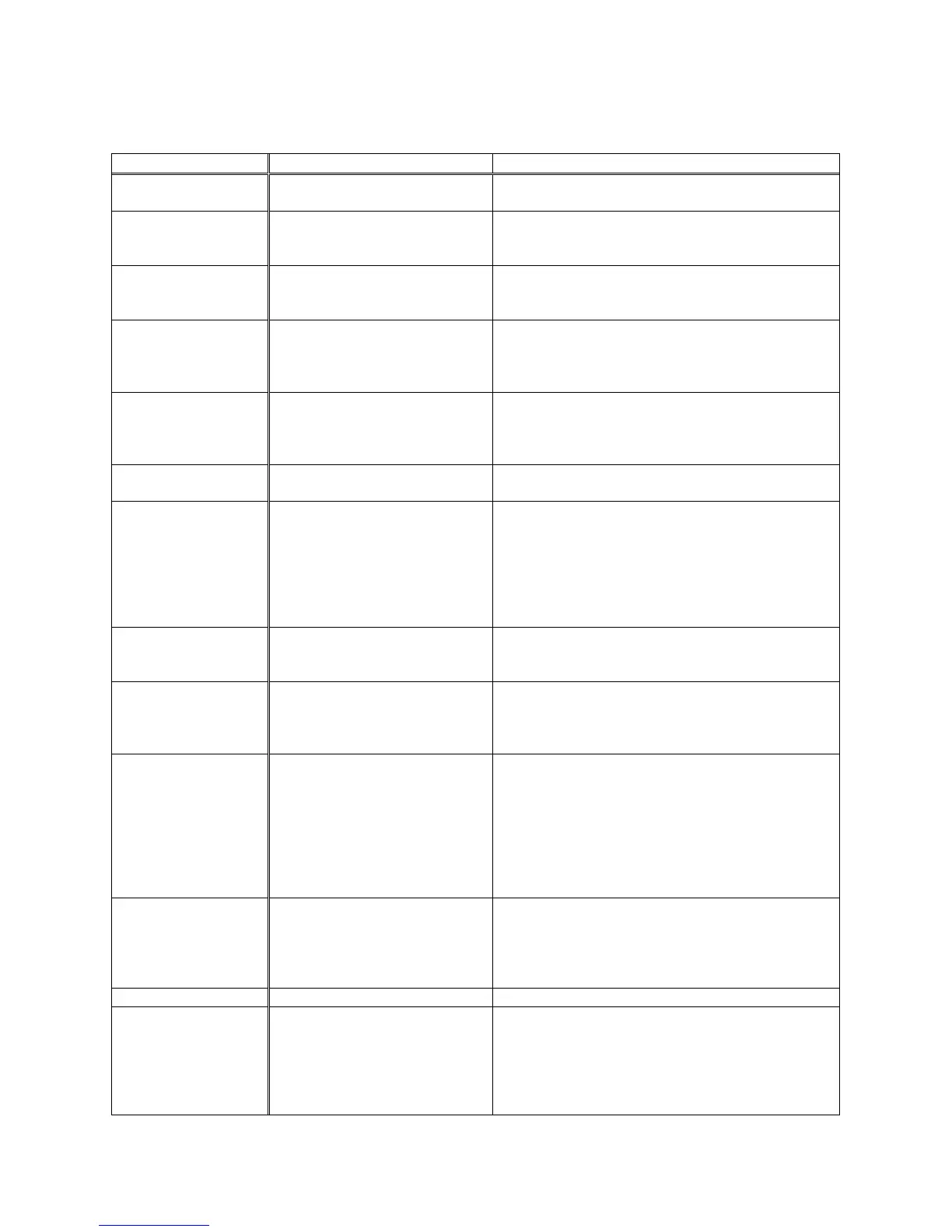

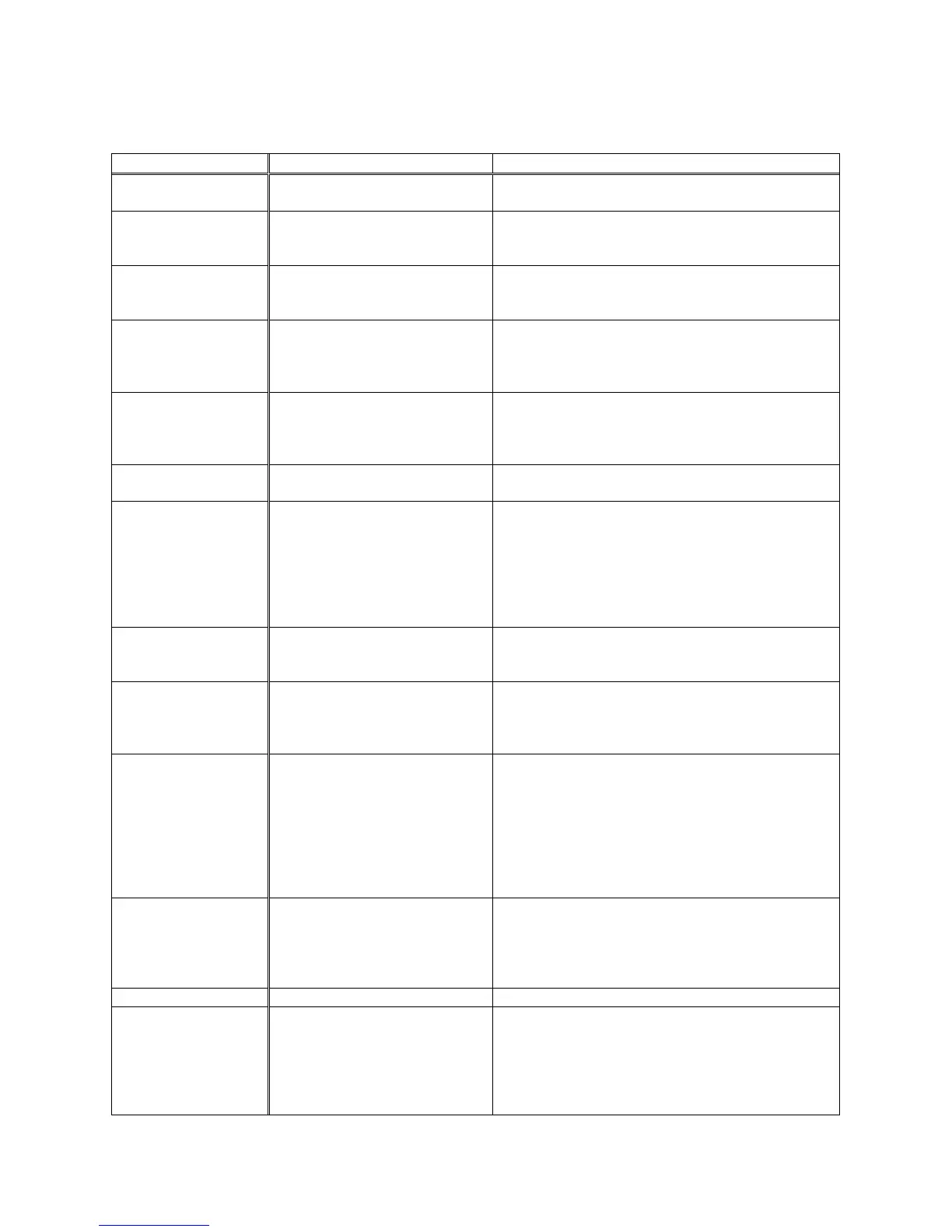

Problem Possible Cause Solution

Conve

or belt does

not move.

Shaft coupler is not attached.

ttach the shaft coupler.

Conve

or rollers run

intermittently.

Shaft couplin

is loose.

li

n the shaft flats of the

ear motor and the

drive roller and tighten the shaft-coupling

setscrews.

brasive strip comes

off drum.

Slack in abrasive strip on

drum.

Abrasive improperly wrapped.

Remove the slack in the strip.

Read the section on wrapping abrasive strips.

brasive strip is

loose.

Strip cau

ht on inside ed

e of

slot, or on inboard side of

drum.

Strip not cut properly.

Re-ad

ust the strip end in the slot and/or trim the

abrasive edge.

Re-cut and re-install the abrasive strip.

brasive loads up

prematurely.

Excessive depth of cut.

Excessive feed rate.

Inadequate dust collection.

Inadequate abrasive.

Reduce the depth of cut.

Use a slower feed rate.

Increase airflow at the dust ports.

Use an open-coat abrasive.

Line or

roove in

stock.

Inconsistent feed rate. Do not stop or chan

e the feed rate.

Wood burns.

brasive strip is overlapped.

Excessive depth of cut.

Excessive depth of cut for fine

grit.

Feed rate is too slow.

Abrasive is loaded.

Worn abrasives.

Re-wrap the abrasive strip.

Reduce the depth of cut.

Use a coarser grit or reduce the depth of cut.

Increase the feed rate.

Clean the abrasives.

Replace the abrasives.

Board slips on

conveyor belt.

Tension rollers are too hi

h.

Excessive feed rate.

Dirty or worn conveyor belt.

Lower the tension rollers.

Reduce the feed rate.

Replace the conveyor belt.

Sander motor slows

or stalls

Improper conve

or belt

tension.

Excessive depth of cut.

Excessive feed rate.

d

ust the belt tension.

Reduce the depth of cut.

Reduce the feed rate.

Rippled sanded

surface

Non-uniformly

paced ripples.

Uniformly spaced

ripples.

Uneven feed rate.

Conveyor bed flexing or

vibration.

Conve

or belt slippin

, see above.

Board slips on conveyor, see above.

Power feed gear motor stalls, see above.

Reduce the depth of cut.

Reduce the feed rate.

Check for loose bolts, shaft-coupling setscrews

or out of balance drum.

Gou

in

of the

wood.

Inconsistent feed rate.

Stock slipping on conveyor.

Work piece not properly

supported.

Maintain constant feed rate

b

hand

.

Excessive depth of cut (PowerFeed) or

inadequate hold down pressure.

Add work supports for long work pieces.

Snipes Improper tension on rollers See tension roller ad

ustment.

Motor overload

protector trips or

shop wiring breaker

trips.

Excessive load on sandin

drum and motor.

Too many tools on circuit.

Excessive length or

inadequate size extension

cord.

llow motor to cool and reset overload button.

Have a certified electrician correct the shop-

wiring problem.

Use a shorter, heavier gauge extension cord.

Loading...

Loading...