– 13 –

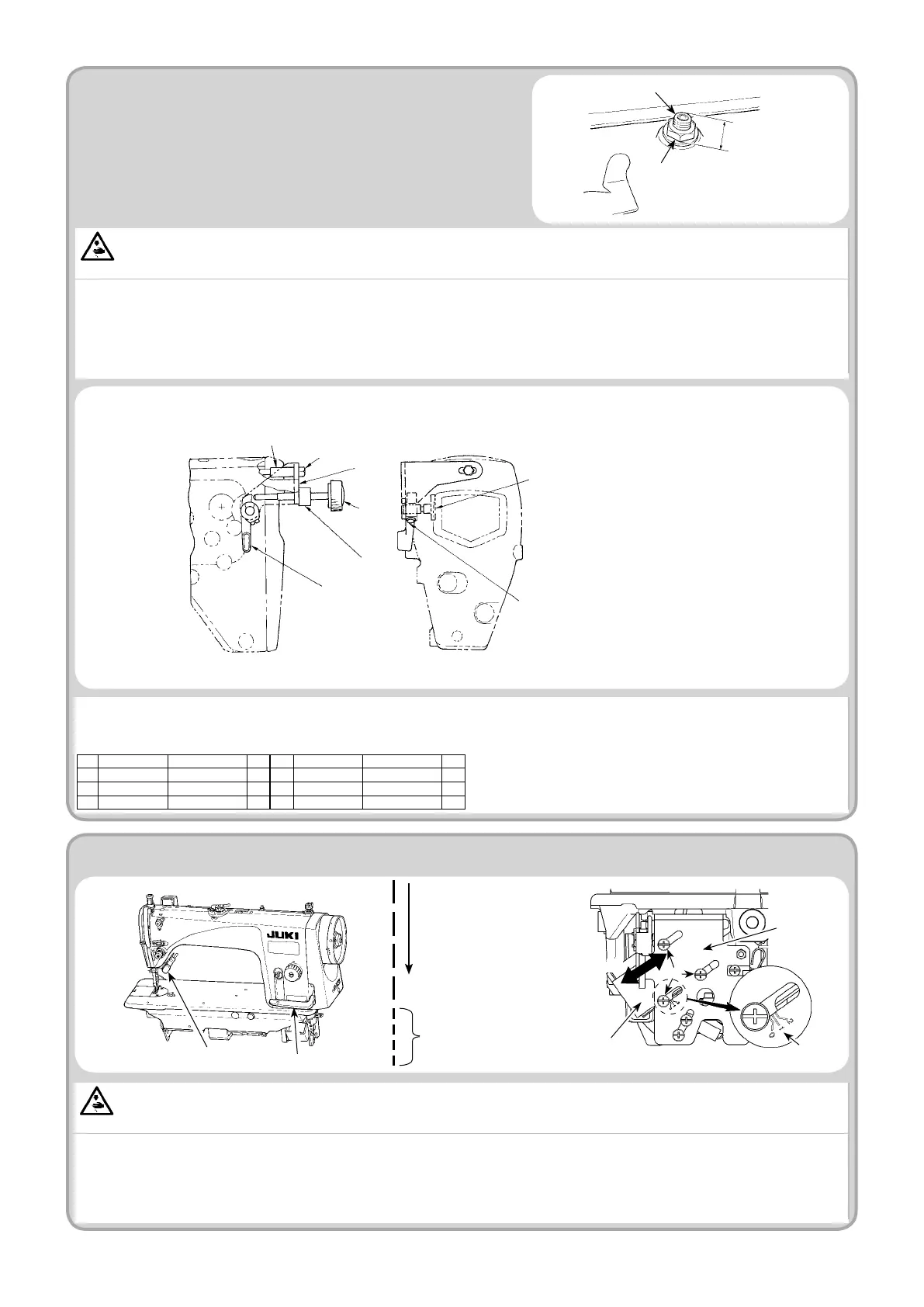

26. MICRO-LIFTING MECHANISM OF THE PRESSER FOOT

For DDL-9000B, the presser foot micro-lifting mechanism is provided as standard. When it is frequently used, however, it is convenient to use the micro-lifting

device (separately available) which can be adjusted without using tools.

Presser foot micro-lifter components

No. Part No. Description

Q’ty

No. Part No. Description

Q’ty

1 23611106 Hand lifter 1 4

D5119206K0K

Collar 2

2 23610504 Stopper base 1 5 23610702 Nut 1

3 23610652 Stopper screw 1 6

SL6053592TN

Setscrew 1

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the sewing machine.

When sewing velvet or the like which is uffy, slippage of material or damage of material is reduced by using screw

1

for presser foot micro-lifting. Lower the

presser foot and set the state that the feed dog is lower than the throat plate.

Gradually tighten screw

1

for presser foot micro-lifting in the state that nut

2

is loosened, nely adjust the position of the presser foot until it matches the

material, and x it with nut

2

.

(Caution) When the presser foot micro-lifting mechanism is not used, adjust the height of screw

1

so that it is higher by approximately 9 mm than

the sewing machine. If the sewing machine is operated in the state that the micro-lifting mechanism is working, sufcient feed force cannot be

obtained.

Approx. 9 mm

1

2

22908552

Hand lifter cam (mounted on the machine head is used)

B1521555000

Hand lifter setscrew (mounted on the machine head is used)

Presser foot micro-lifter (asm.) [40056622] (Separately available)

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the sewing machine.

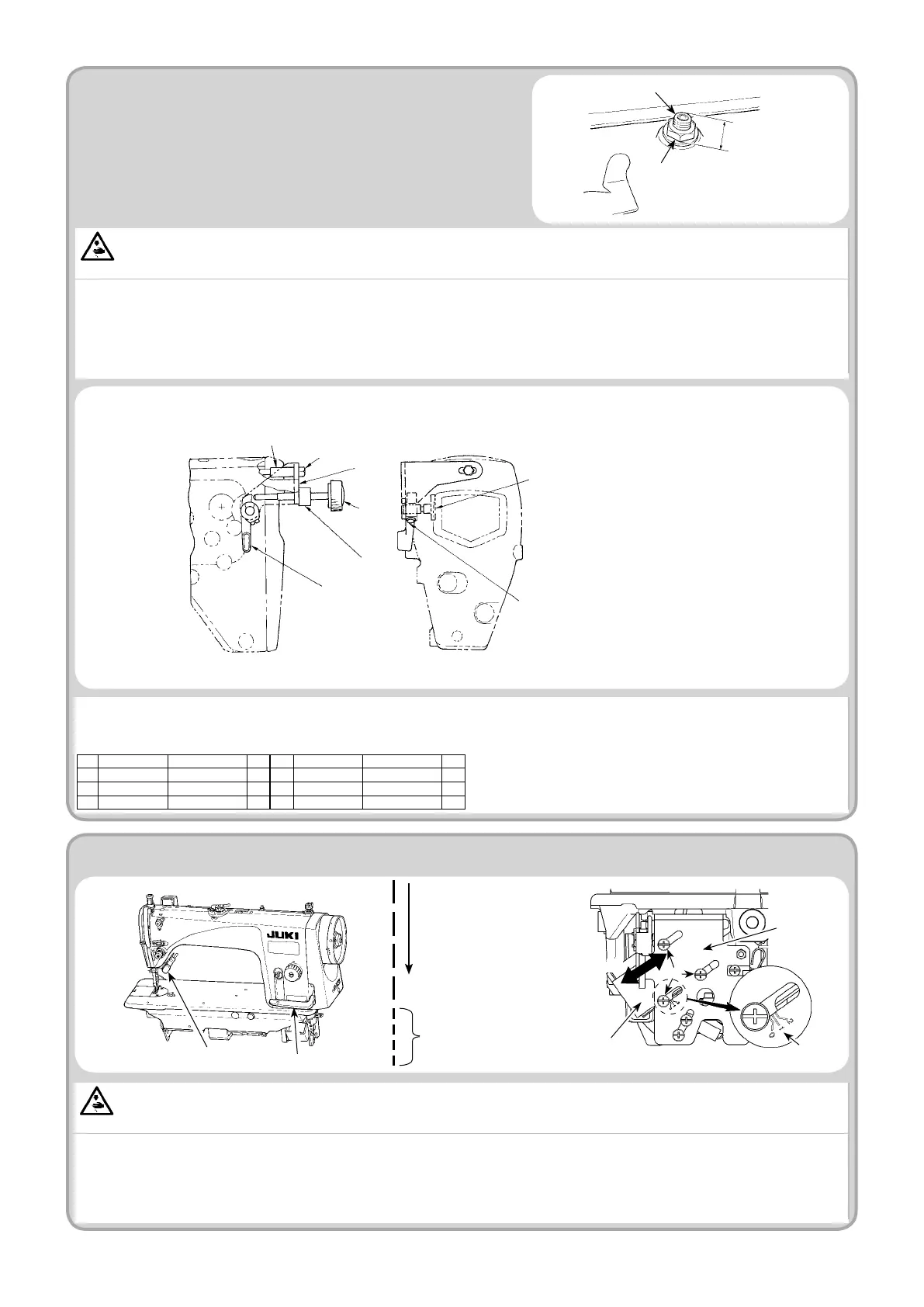

It is possible to change the stitch length of the normal feed pitch by operating switch

1

or reverse feed control lever

2

during sewing.

1)

Tilt the machine head, and loosen three xing screws

4

of the reverse feed solenoid

3

.

2) Slide reverse feed solenoid

3

in the direction of the arrow to adjust so that the center of screw

4

is aligned with engraved marker line

5

representing the

condensation stitch length. Then x the solenoid with setscrews

4

.

3)

To return the stitch length back to the initial setting (to reset), slide reverse feed solenoid

3

in the direction of arrow

A

until it comes in contact with the end

face of slit in bed strut B

6

. Then, x the solenoid at that position with setscrews

4

.

Sewing direction

Condensed stitch

27. SEWING CONDENSED STITCHES

1

2

6

3

4

A

5

1

5

3

2

6

4

Loading...

Loading...