– 21 –

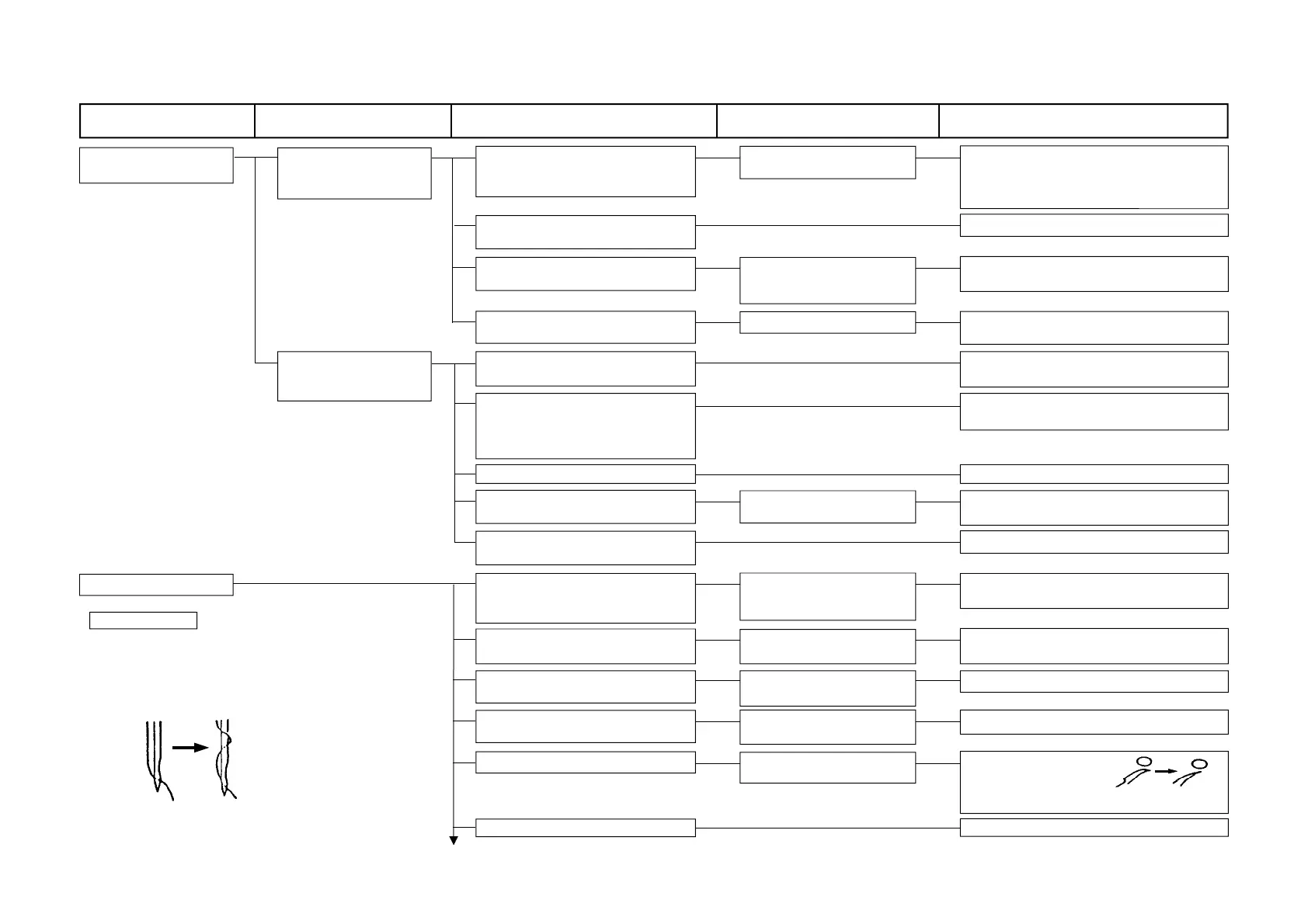

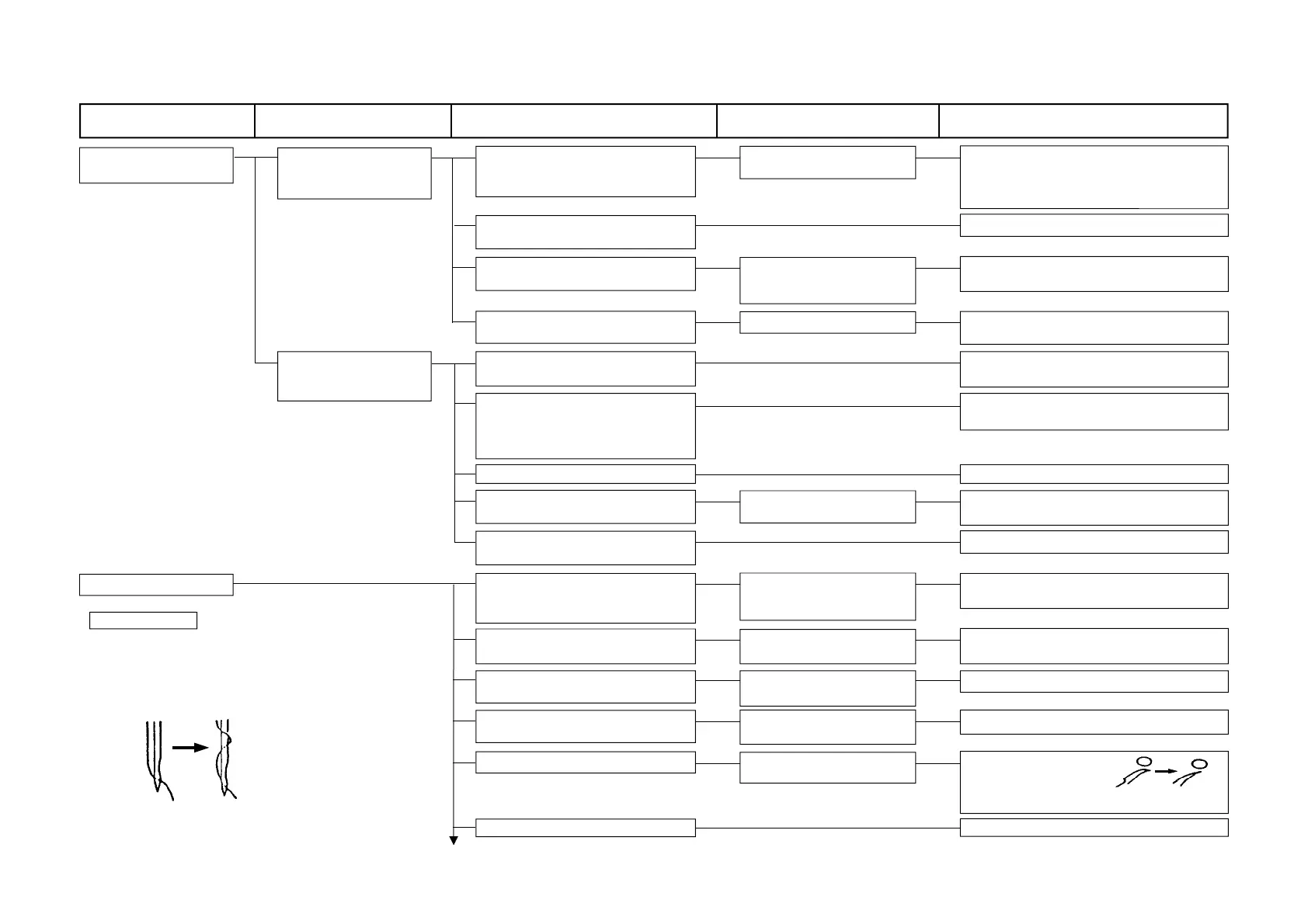

1. Needle Thread 1-1) Needle thread splits 1-A) Scratches in needle path, needle A-1) Check the scratches in For the scratches on the hook blade point, polish

Breakage finely or breaks tip, hook blade point, or throat plate each section. the hook blade point with fine sandpaper. For the

during sewing. bobbin case resting groove section. groove section on the throat plate, finish it off,

using a buff.

1-B) Needle thread tension is Adjust the needle thread tension properly.

excessive.

1-C) Needle comes in contact with C-1) Check for the clearance Refer to 3.-(2) Timing between the Needle and

the blade point of the hook. between the needle and the Hook.

the hook.

1-D) Oil level in the hook is insu- D-1) Check the oil level. Replenish oil properly. Refer to 3.-(12) Lubri-

fficient. cation.

1-2)

2 to 3 cm of the needle

2-A) Needle thread tension is Adjust the needle thread tension properly (in many

thread is left on the insufficient. cases, it is caused by synthetic thread).

rear of the material.

2-B) Tension of the thread take-up Re-adjust the thread take-up spring tension

spring is too high or stroke of and stroke.

the thread take-up spring is too

small.

2-C) Feed timing is improper. Refer to 3.-(5) Timing of the Cloth Feed Action.

2-D)

Timing between the hook and the

D-1) Check for the specified Refer to 3.-(2) Timing between the Needle and

needle is too early or too late. dimensions. the Hook.

2-E) Needle generates heat, resu- Decrease the sewing speed, or use silicon oil.

ting in thread breakage.

2. Stitch Skipping 2-A) Clearance between the needle A-1) Check for the clearance Refer to 3.-(2) Timing between the Needle and

and the blade point of the hook between the needle and the Hook.

is too large.

the blade point of the hook.

2-B) Timing between the needle and B-1) Check for the specified Refer to 3.-(1) Height of Needle Bar and

the hook is too early or too late. dimensions.

3.-(2) Timing between the Needle and the Hook.

2-C) Presser foot fails to rest on throat C-1) Check for the presser Fasten the presser adjusting screw.

plate. (Pressure is too low) foot pressure.

2-D) Height of the needle bar is D-1) Check for the needle Refer to 3.-(1) Height of Needle Bar.

incorrect. bar lowest dead point.

2-E) Blade point of the hook is blunt. E-1) Check for the blade Repair the blade point of

point shape. the hook or replace the

hook with a new one.

2-F) Selected needle is incorrect. Select the needle which is one-rank thicker.

Problems Description Causes Check Treatment and Corrective Measures

7. Trouble in Sewing and Corrective Measures

Test Report

o In the case that needle thread breakage and stitch skip-

ping occurs frequently, in particular when synthetic thread

is used:

(TETLON #30 to TETLON # 40)

1. It will be improved if the thread is wound around the

needle.

oTo decrease the lifting amount of the presser foot will help

with needle breakage.

Needle

Blade point

of the hook

To the next page

Loading...

Loading...