– 1 –

BEFORE OPERATION

CAUTION :

Check the following so as to prevent maloperation of and damage to the machine.

• Before you put the machine into operation for the fi rst time after the set-up, clean it thoroughly .

Remove all dust gathering during transportation and oil it well.

• Confi rm that voltage has been correctly set.

Confi rm that the power plug has been properly connected to the power supply.

• Never use the machine in the state where the voltage type is different from the designated one.

• The direction of normal rotation of the machine is counterclockwise as observed from the pulley side.

Take care not to allow the machine to rotate in the reverse direction.

• When tilting the machine head, tilt it after removing knee lifter hook.

• Never operate the machine unless the machine head and the oil tank have been fi lled with oil.

• For a test run, remove the bobbin and the needle thread.

• For the fi rst month, decrease the sewing speed and run the sewing machine at a speed of 1,800 sti/min or less.

• Operate the handwheel after the machine has totally stopped.

1. INSTALLATION OF THE MACHINE

SPECIFICATIONS

1. Carry the sewing machine with two persons.

(Caution) Do not hold the handwheel.

2.

Do not put protruding articles such as the screwdriver and the

like at the location where the sewing machine is placed.

3. Mounting positions of the knee lifter and the oil pan

(Caution) The knee lifter should be mounted before the

motor is installed.

Stitch system 1-needle, top & bottom feed, lockstitch machine Needle

Schmetz 1738 Nm125 to Nm160 (standard: Nm130)

Application Medium- to heavy-weight materials (Schmetz 135×17 Nm90 to Nm160)

Sewing speed Max. 2,000 sti/min

Count of thread to be used

#40 to #8

Stitch length Max. 9 mm

Stitch adjustment method

By dial

Lift of presser foot By lifting lever 6 mm, By knee lifter 15 mm Lubrication method By an oiler

(The hook is automatically lubricated.)

Thread take-up Link type thread take-up Motor to be used AC servo motor

Needle bar stroke 37 mm Lubrication oil JUKI New defrix oil No.1

Noise - Equivalent continuous emission sound pressure level (L

pA

) at the workstation:

A-weighted value of 77.5 dB; (Includes K

pA

= 2.5 dB); according to ISO 10821- C.6.2 -ISO 11204 GR2 at 2,000 sti/min.

Oilpan

– 6 –

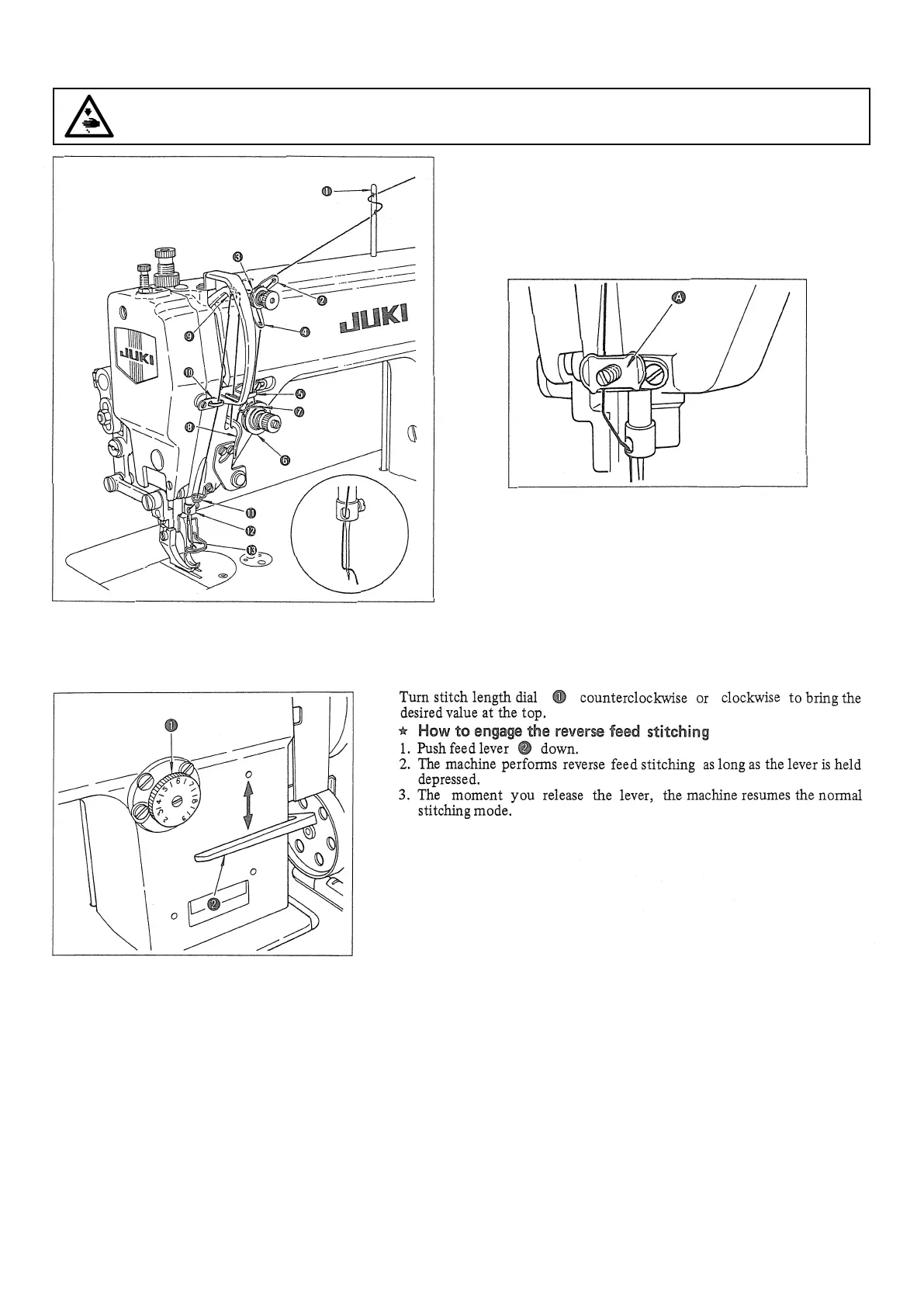

10. THREAD THE MACHINE HEAD

WARNING :

To avoid possible personal injury due to abrupt start of the machine, turn off the power to the machine and check to be sure that the

motor has totally stopped rotating in prior.

Thread the machine head in the order of

1

through to

!3

.

* If using a tetron thread or the like, the thread may come off the needle

eyelet after thread trimming. In this case, replace the take-up thread

guide which is currently used with take-up thread guide

A

supplied

with the machine. (Refer to the fi gure in the lower.)

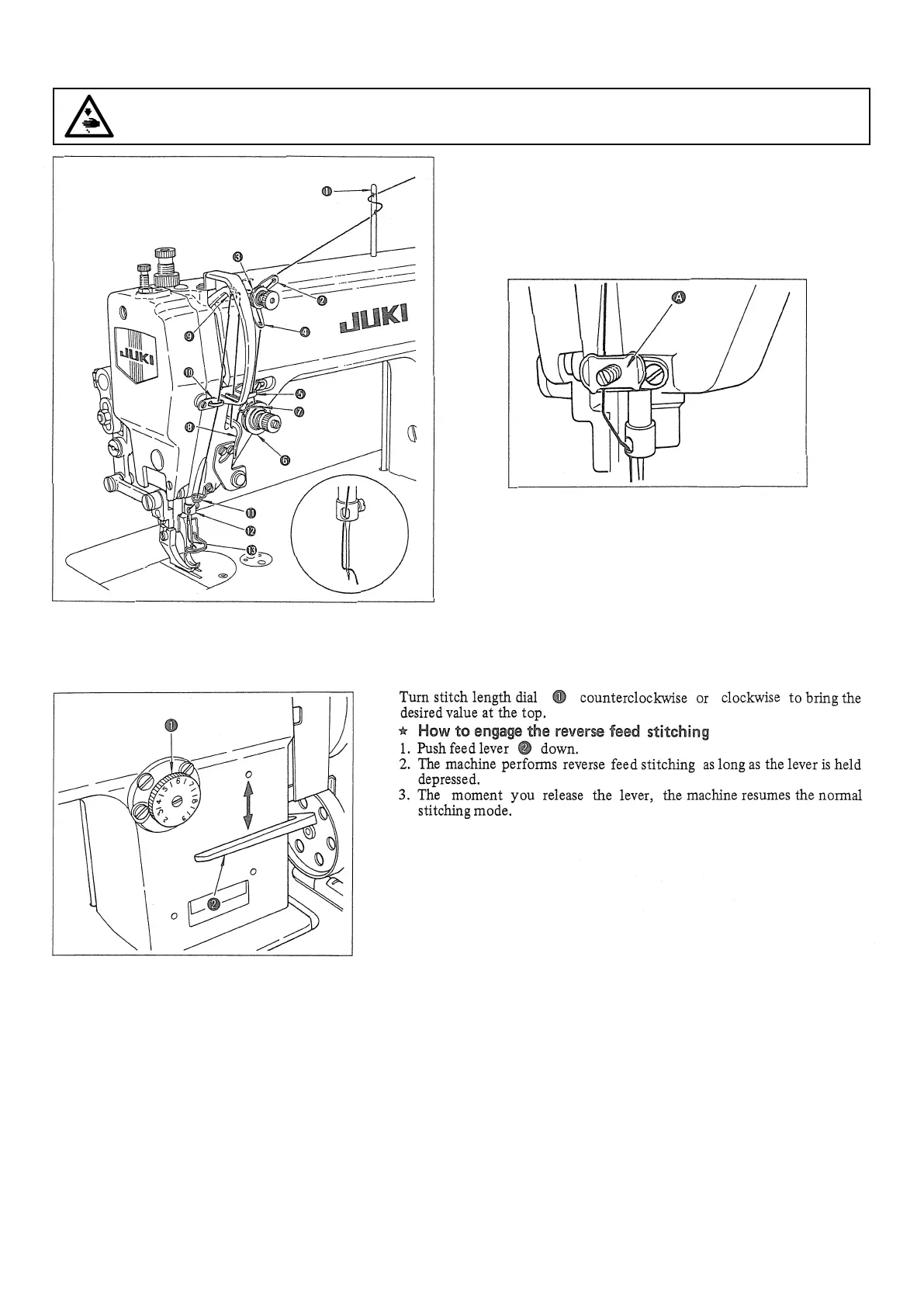

11. ADJUSTING THE STITCH LENGTH

Loading...

Loading...