øA

øB

A

B

A

B

A

B

SM8040302TP

L

A

B

SM8040302TP

L

77

2422

14 14

36

LK1900AN S000

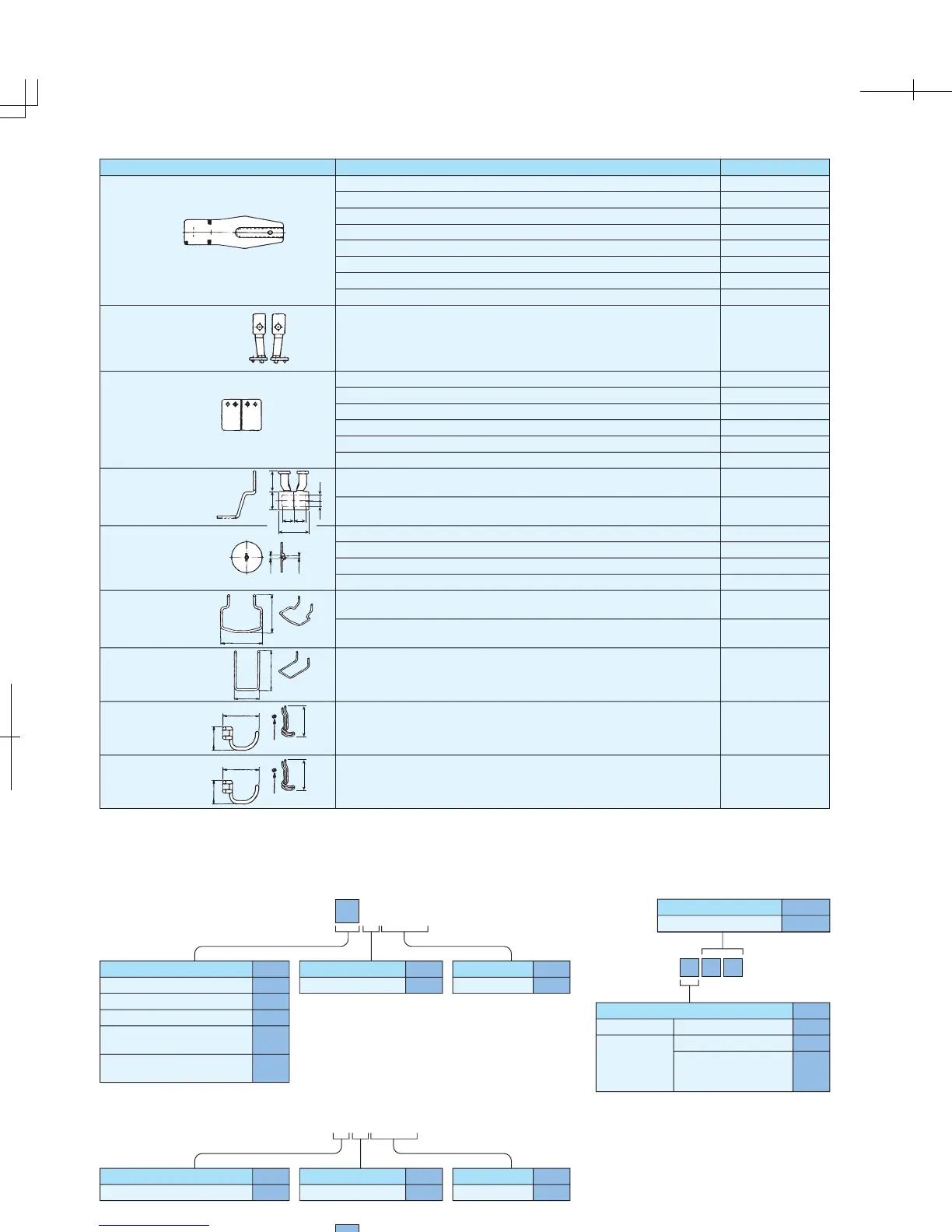

■ TABLE OF THE OPTIONAL PARTS

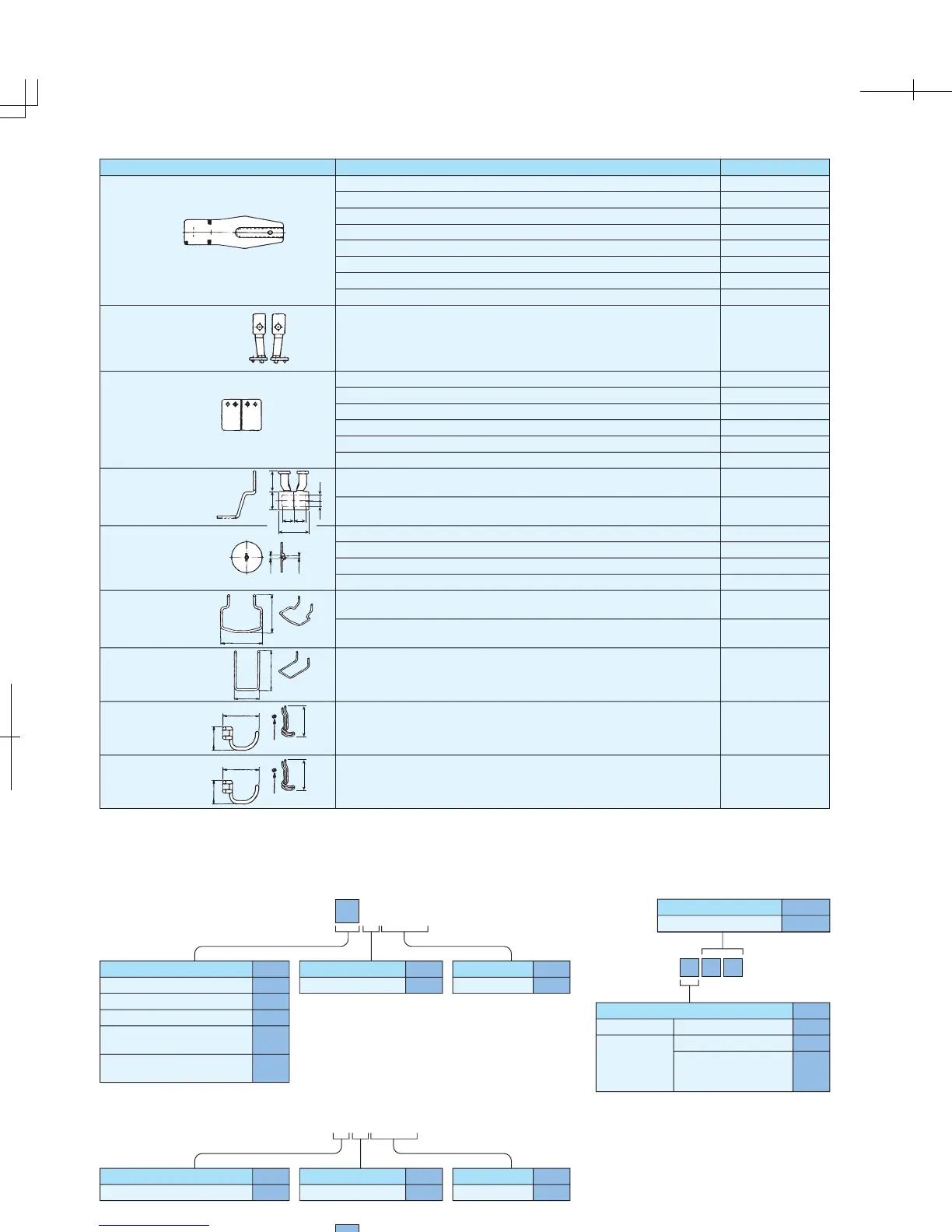

■ WHEN YOU PLACE ORDERS

●Bartacking

●Eyelet buttonhole bartacking

●Belt-loop attaching

MC598

[Machine head] [Control box]

The LK-1900AN model comes in five different type models, such as S type (standard), H type (for heavy-weight

materials), F type (for foundation), M type (for knits and knitted materials) and W type (with a large shuttle hook

for heavy-weight materials), to offer a choice according to any application.

The needle's penetrating force into the material has been increased. This provides an improved responsiveness to heavy-

weight materials for the H type machine.

The W type has adopted a large shuttle hook, which reduces the frequency of bobbin-thread changing to enable

highly efficient sewing work.

The machine is provided as standard with an auto-lifter that uses a

stepping-motor system.

Many different models are prepared according to the type of materials.

Excellent workability and operability.

Application Code

Standard S

For heavy-weight materials H

For foundation F

For knits and knitted

materials

M

With large hook

for heavy-weight materials

W

Power supply Code

3-phase 200

~240V E

Single-phase

200~240V K

CE 200~240V

(not provided with

power switch)

N

Attachment Code

Not provided 000

Work clamp foot

Code

Standard S

LK1902AN S000

Application Code

Standard S

For heavy-weight materials H

Attachment Code

Not provided 000

Work clamp foot

Code

Standard S

LK1901ANSS000

Application Code

Standard S

Attachment Code

Not provided 000

Work clamp foot

Code

Standard S

The direct-drive head (with no belt), which is directly connected to a compact AC servomotor, achieves outstanding

responsiveness and improved stop accuracy. This head helps create a comfortable working environment with reduced

vibration and noise.

The arm section of the machine head is fitted with a hand pulley. This allows the operator to visually check the

needle entry points.

The sewing starting point can be corrected.

The sewing starting point can be shifted in the X/Y direction. This enables the correction of a sewing pattern in

accordance with the presser foot configuration.

It is also possible to change over the stroke of the auto-lifter from a one-step stroke to a double-step stroke, which offers

easier positioning of a material on the machine. For the double-step stroke, an intermediate stopping height can be

established on the operation panel.

The presser foot lift can be set to a maximum of 17mm by using the reverse-rotation needle-up function in combination

with the auto lifter mechanism.

Please note when placing orders, that the model name should be written as follows:

●To order, please contact your nearest JUKI distributor.

Operation panel Code

Standard panel SS

Part name Type Part No.

Feed plate blank Without knurl/with plating Sewing area 20

×40 14120109

With knurl/with plating Sewing area 20

×40 14120307

Without knurl/stainless steel

✽

Sewing area 20×40 14120505

Without knurl/with plating Sewing area 30×40 40021855

Without knurl/without plating Sewing area 30

×40 40021856

Without knurl/stainless steel

✽

Sewing area 30×40 40021857

With knurl/with plating Sewing area 30

×40 40021858

With knurl/without plating Sewing area 30

×40 40021859

Work clamp foot

face plate (asm.)

Face plate for presser blank 14121263

Presser blank With knurl/with plating (right) Sewing area 20

×40 14121701

With knurl/with plating (left) Sewing area 20

×40 14121800

With knurl/with plating (right) Sewing area 30

×40 40021851

With knurl/with plating (left) Sewing area 30×40 40021852

With knurl/without plating (right) Sewing area 30

×40 40021853

With knurl/without plating (left) Sewing area 30×40 40021854

Work clamp foot blank

With knurl/with plating (right) 40021869

With knurl/with plating (left) 40021870

Needle hole guide A=1.6 B=2.6 With relief slit Standard type B2426280000

A=1.6 B=2.0 Without relief slit F and M types D2426282C00

A=2.3 B=4.0 Without relief slit for heavy-weight material 14109607

A=2.7 B=3.7 Without relief slit for extra heavy-weight material D2426MMCK00

Finger guard (1)

A=56.5 B=64 13533104

A=59 B=74 For extra-large bartacking 13548300

Finger guard (2)

A=66.5 B=43 For lengthwise bartacking 13573407

Finger guard (3)

A=21.5 B=35.5 L=67 For lengthwise bartacking 14135305

Finger guard (4)

A=21.5 B=35.5 L=58.5 For specially ordered work clamp 14120000

t=1.2

✽Stainless steel t=0.5

t=3.2

S type (Bartacking pocket lip of suits) H type (Bartacking crotch of jeans)

F type (

Attaching the shoulder straps to brassier

) M type (

Bartacking shoulder of running shirt

)

✽ Presser foot for vertical bartacking is supplied with

the unit as an accessory.

Loading...

Loading...