−2 −

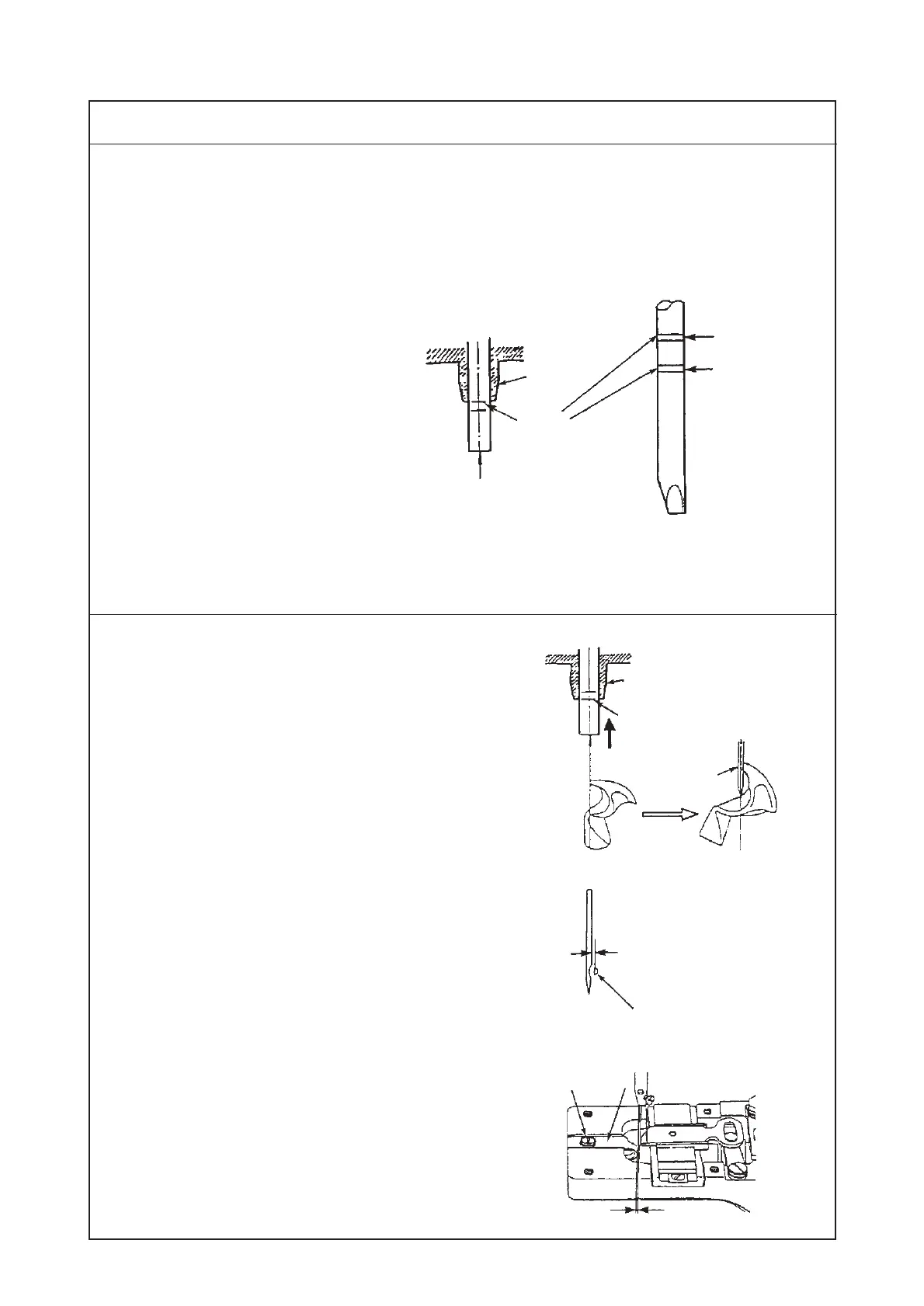

(1) Height of the needle bar

The upper engraved line should be aligned with the bottom of lower bushing 3 when the needle bar is

at its lowest position.

Standard needle for MB-373 : TQ x 7

Standard needle for MB-377 : TQ x 1

2. STANDARD ADJUSTMENT

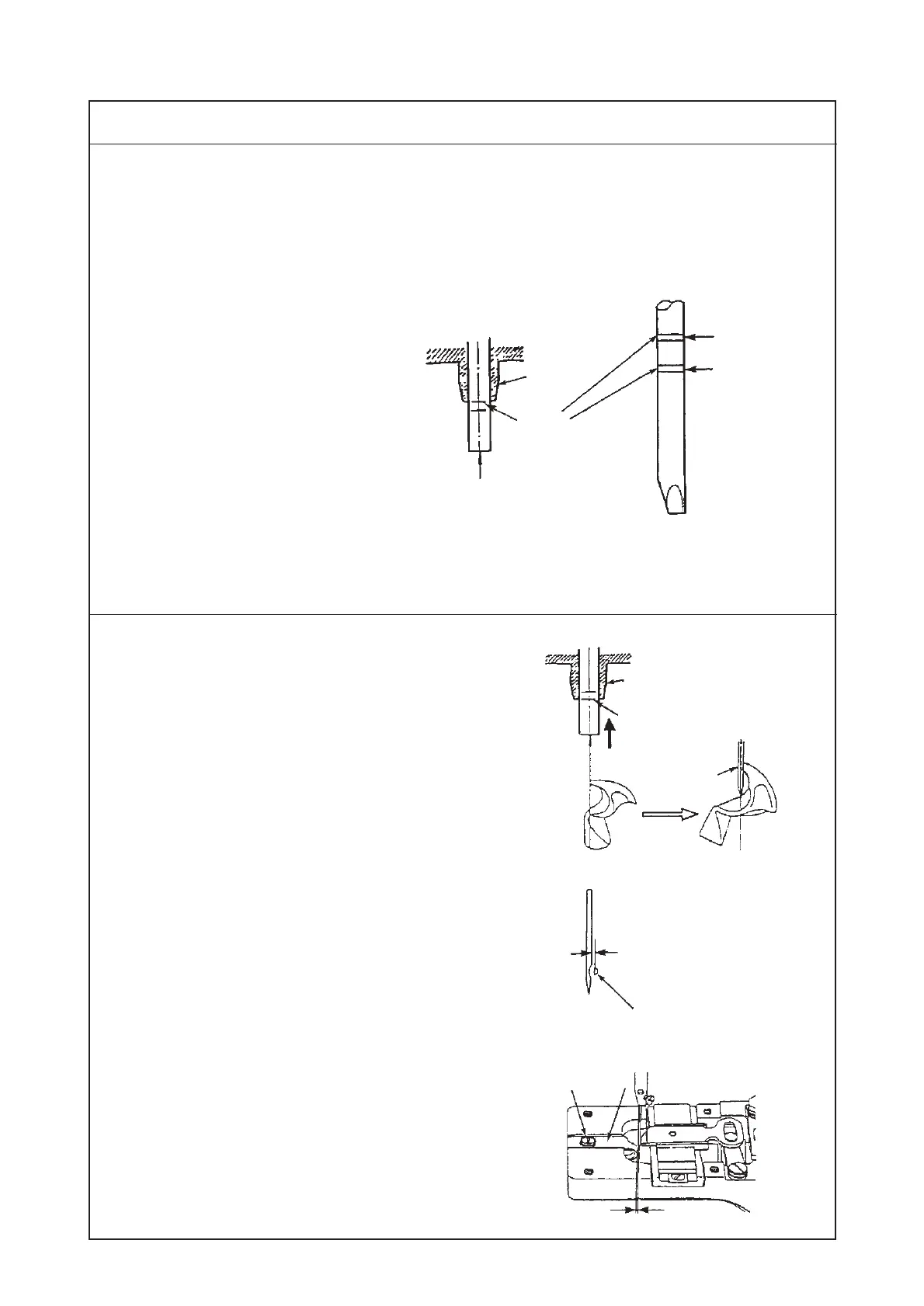

(2) Positioning the needle and the looper

1) Looper timing

When the needle bar is ascending from its lowest

position and the lower engraved line on the needle

bar is aligned with the bottom of the lower bushing,

the looper’s blade point should coincide with the

center of the needle. (When the needle bar is

ascending.)

2) Clearance between the needle and looper

The clearance is 0.01 to 0.1 mm when the looper’s

blade point coincides with the center of the needle.

3) Clearance between the needle guide and needle

The clearance between needle guide 6 and

needle is 0 to 0.1 mm when the needle bar is at its

lowest position.

Standard Adjustment

For TQ x 1

For TQ x 7

Engraved line

Height of the needle bar

Looper timing

Lower bushing

Engraved line

Clearance between needle and looper

0.01 to 0.1 mm

Looper’s blade point

Looper’s blade

point coincides

with center of

needle.

Clearance between needle and looper

0 to 0.1 mm

3

6

8

Loading...

Loading...