–

33

–

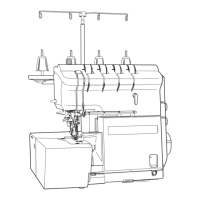

Adjustment Procedure

Results of Improper Adjustment

Checking items:

❶

Lower looper

❷

Upper looper

* Check that the clearance between the projecting part of the lower

looper

❶

and the blade point of the upper looper

❷

is 1 ± 0.5 mm

(A) when the upper looper goes up and the upper looper blade point

meets the lower looper.

* Check that the front-to-back clearance between the upper looper blade

point and the lower looper

❶

is 0.1 to 0.3 mm (B).

How to perform adjustment:

○

Loosen the setscrews (E) of the upper looper cam.

○

Rotate the upper looper cam (D) to make adjustment (A).

○

Retighten the setscrews (E).

○

Loosen the setscrew (C) of the upper looper

❷

.

○

Move the upper looper

❷

front back to make adjustment (B).

○

Retighten the setscrew (C).

If the clearance is larger than the

standard adjustment value, stitch

skipping can be caused.

If the clearance is smaller than the

standard adjustment value, the

relevant parts can come in contact

with each other, resulting in abnor-

mal noise and abrasion.

Loading...

Loading...