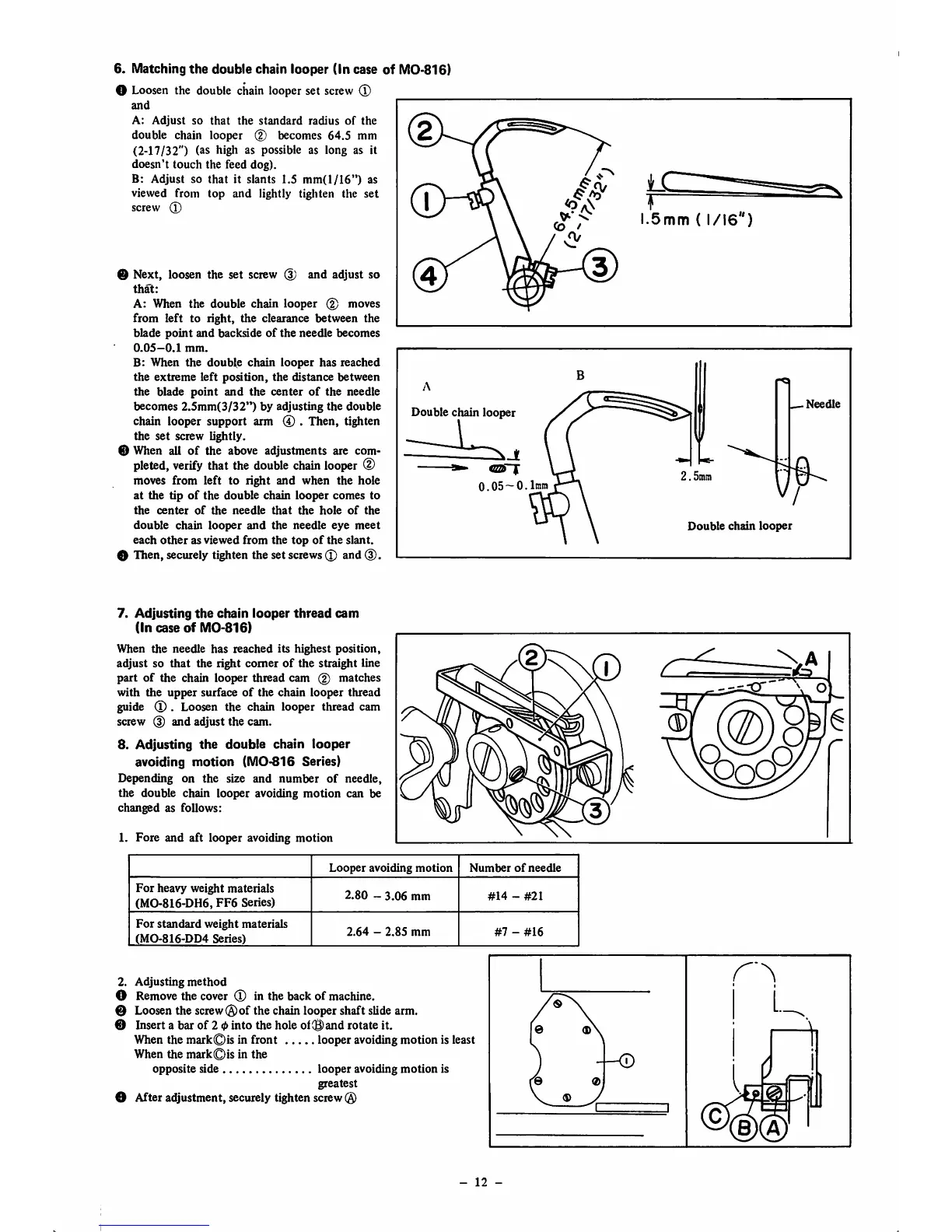

6. Matching

the

double

chain

looper

(In case of MO-816)

O Loosen the double chain looper set screw (l)

and

A:

Adjust

so

that

the

standard

radius

of

the

double

chain

looper

(2)

becomes

64.5

mm

(2-17/32")

(as high as possible as long as it

doesn't touch the feed dog).

B:

Adjust

so

that

it

slants

1.5

mm(l/16")

as

viewed from

top

and lightly tighten the

set

screw ®

Next,

loosen

the

set screw (3)

and

adjust

so

that:

A: When

the

double

chain

looper

(2) moves

from

left

to right, the clearance between the

blade

point

and

backside

of

the

needle becomes

0.05—0.1

mm.

B: When

the

double

chain

looper

has

reached

the

extreme

left

position,

the

distance

between

the blade

point

and

the

center

of

the needle

becomes

2.5mm(3/32")

by adjusting

the

double

chain looper support arm ® . Then, tighten

the

set

screw lightly.

When

all

of

the

above

adjustments

are

com

pleted,

verify

that the

double

chain

looper

®

moves from

left

to right and when the hole

at the tip

of

the double chain

looper

comes to

the

center

of

the

needle

that

the

hole

of

the

double

chain

looper

and

the

needle

eye

meet

each

other

as viewed

from

the

top

of

the

slant.

Then, securely tighten the set screws (D and (3).

Double

chain

looper

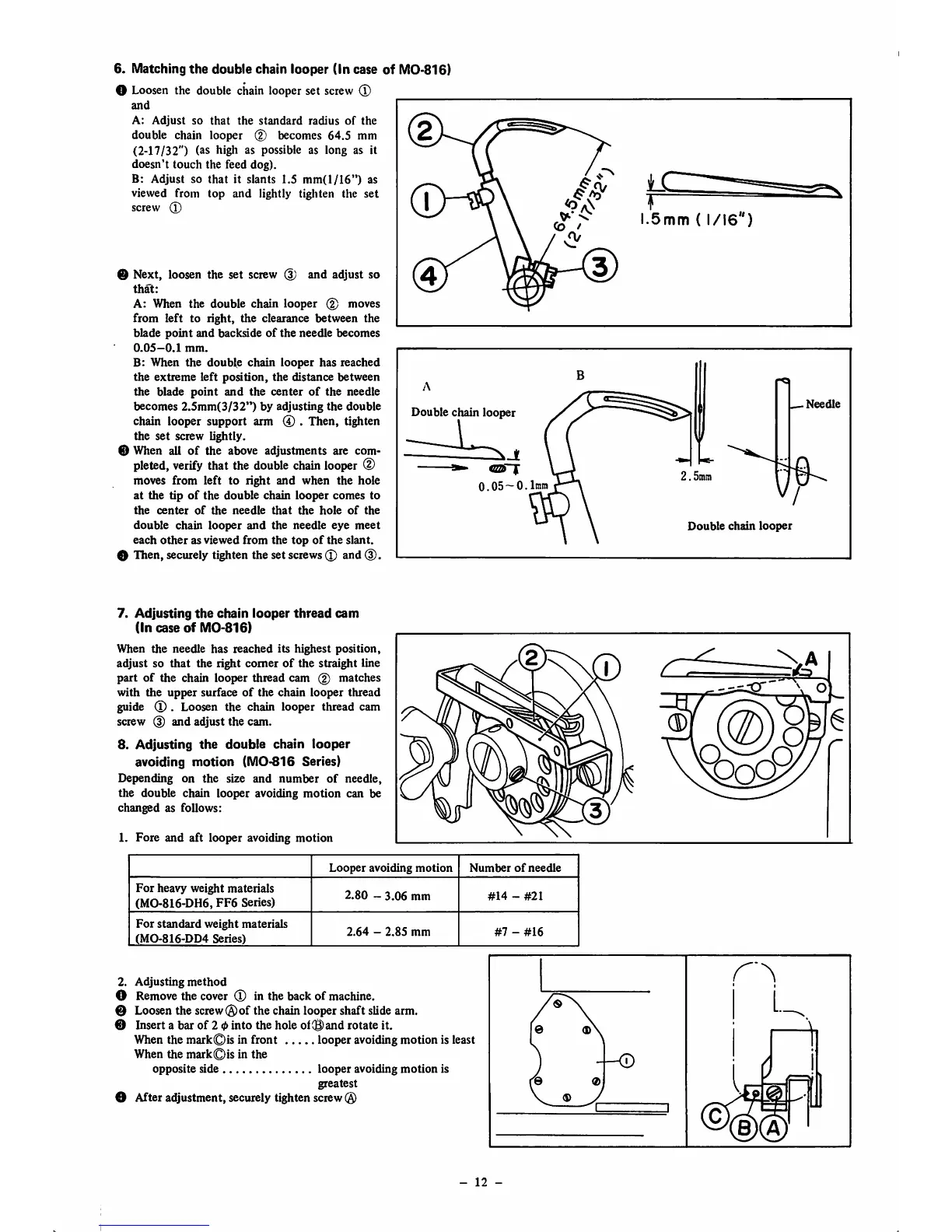

7.

Adjusting

the

chain

looper

thread

cam

(in

case

of

MO-816)

When

the

needle

has

reached

its

highest

position,

adjust so

that

the right

comer

of

the straight line

part

of

the chain looper thread cam (2) matches

with the

upper

surface

of

the chain looper thread

guide (D . Loosen the chain looper thread cam

screw (D and adjust the cam.

8.

Adjusting

the

double

chain

looper

avoiding motion (MO-816 Series)

Depending

on

the

size

and

number

of

needle,

the

double

chain

looper

avoiding

motion

can be

changed

as follows:

1.

Fore

and

aft looper avoiding

motion

0.05—0.1mm

Looper

avoiding

motion

Number

of

needle

For

heavy

weight

materials

(MO-816-DH6,

FF6

Series)

2.80

-

3.06

mm

#14

-

#21

For

standard

weight materials

(MO-816-DD4

Series)

2.64

-

2.85

mm

#7

-

#16

2.

Adjusting

method

O Remove the cover (D in the back of machine.

@ Loosen the screw®of the chain looper shaft slide arm.

0 Insert a bar of 2 0 into the hole oKBand rotate it.

Whenthe mark©is in front looper avoidingmotion is least

When the

mark©is

in the

opposite

side

looper

avoiding

motion

is

greatest

O After adjustment, securely tighten screw®

-

12

-

5mm

(

I/I6')

^Needle

2.5mm

Double

chain

looper

Loading...

Loading...