19

ANTRIEBSTECHNIK

M

3~

PE

L1, L2, L3

3. EMC

Fundamentals

3.1 General

Frequency inverters / servo drives represent electrical equipment designed for use in

industrial and commercial units. In accordance with the EMC directive 89/336/EEC, it

is not obligatory to mark these devices as they represent components to be further

processed by the respective machine and unit manufacturer and are not operable

independently according to the EMC directive. The person installing / operating the

machine / unit is obliged to proove the protective measures demanded by the EMC

directive are complied with. The prescribed ratings can usually be complied with when

using the radio interference voltage filters specified by KEB, and when observing the

following measures and installation guidelines.

The KEB frequency inverter / servo drive is designed to be used in the second

environment as defined in EN 61800-3 (unit with its own supply transformer).

Take additional measures when using it in the first environment (residential and

commercial area connected to public low-voltage mains)!

; Install the cabinet or system correctly.

; To avoid coupled-in noise, separate

• mains / supply lines

• motor lines from inverters / servo actuator

• control and data lines (low-voltage level < 48V)

and leave a space of at least 15 cm between them when installing.

; In order to maintain low-resistance high frequency connections, earthing and

shielding, as well as other metallic connections (e.g. mounting plate, installed units)

must be in metal-to-metal contact with the mounting plate, over as large an area

as possible. Use earthing and equipotential lines with a section as large as possible

(min. 10mm

2

) or use thick earthing strips.

; Only use shielded cable with copper or tin-plated braid, since steel braid is not

suitable for high frequency ranges. The screen must always be installed on the

compensating rail and fastened with clips or guided through the wall of the housing

with metal screw connections. Do not elongate the screen end (pigtails) with

individual conductors!

; If external interference suppression filters are used, then these must be installed

as close as possible to (<30cm from) the interference source and in metal-to-metal

contact with the mouting plate, over as large an area as possible.

; Always equip inductive control elements (contactors, relays etc.) with suppressors

such as varistors, RC-elements or damping diodes.

; All connections must be kept as short as possible and as close as possible to the

earth, as free floating lines work as active and passive aerials.

; Keep connection cables straight (do not bundle). Install a non-assigned wire on

both sides of the protective conductor.

; The flow and return circuit must be twisted when the lines are not shielded, in order

to dampen common-mode noise.

; Further informations are found in the instruction manual part 2/3.

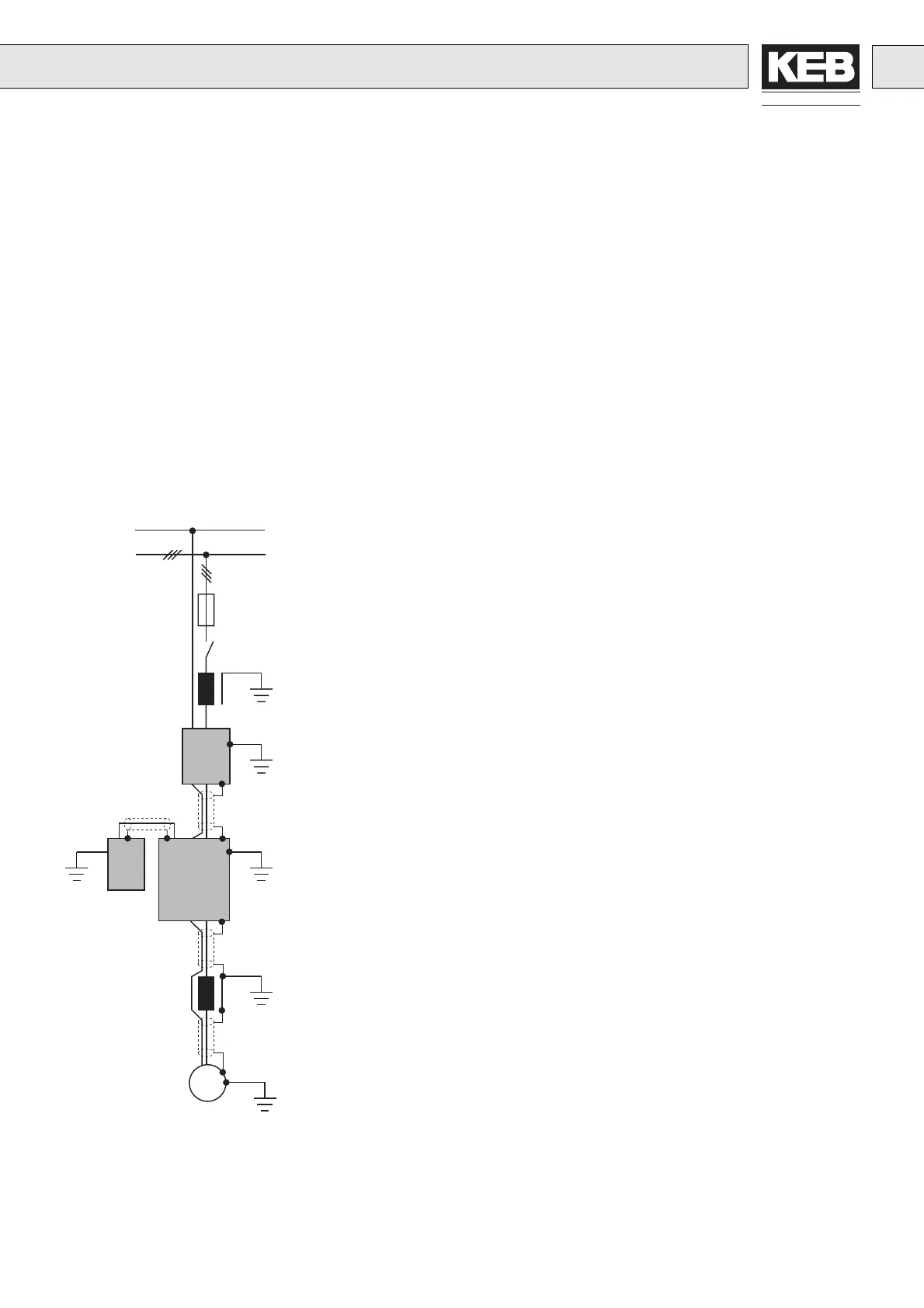

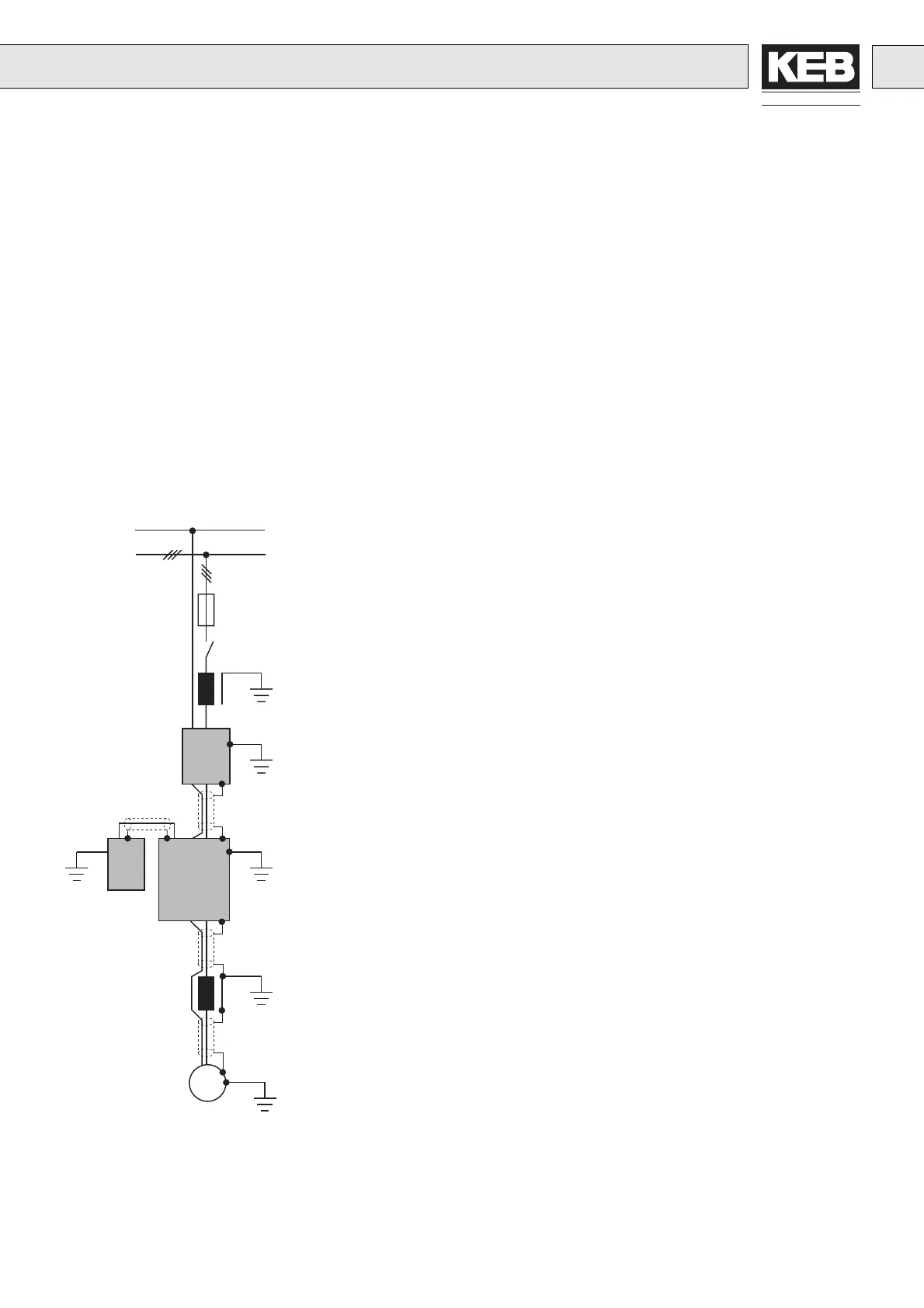

1. Mains Fuse

2. Main Protection

3. Line Reactor

4. Interference Suppression Filter

(if not already installed)

5. Inverter with Braking Resistor

6. Motor Choke or Output Filter

7. Motor

1

2

3

4

5

6

7

3.2 Installation

Loading...

Loading...