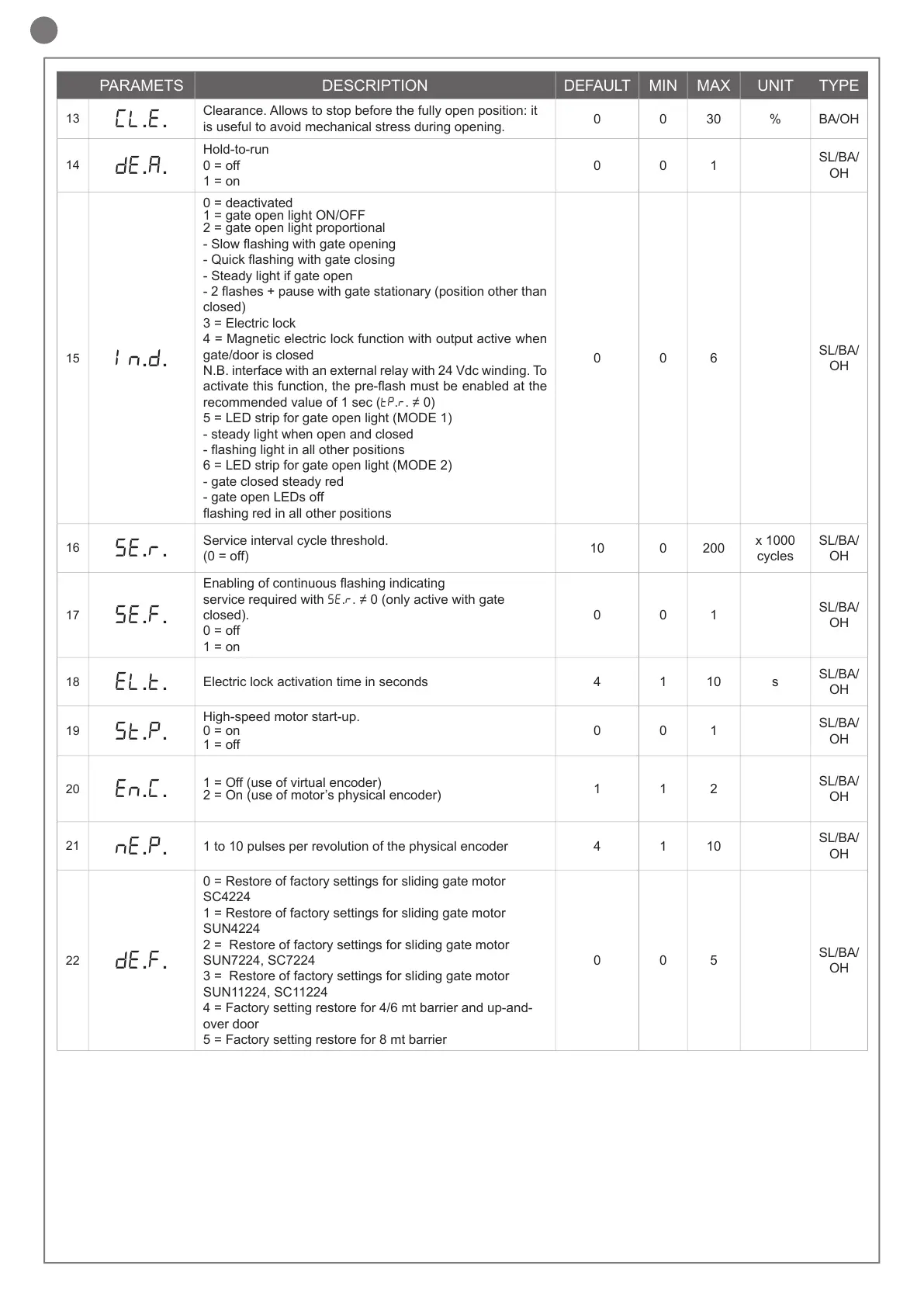

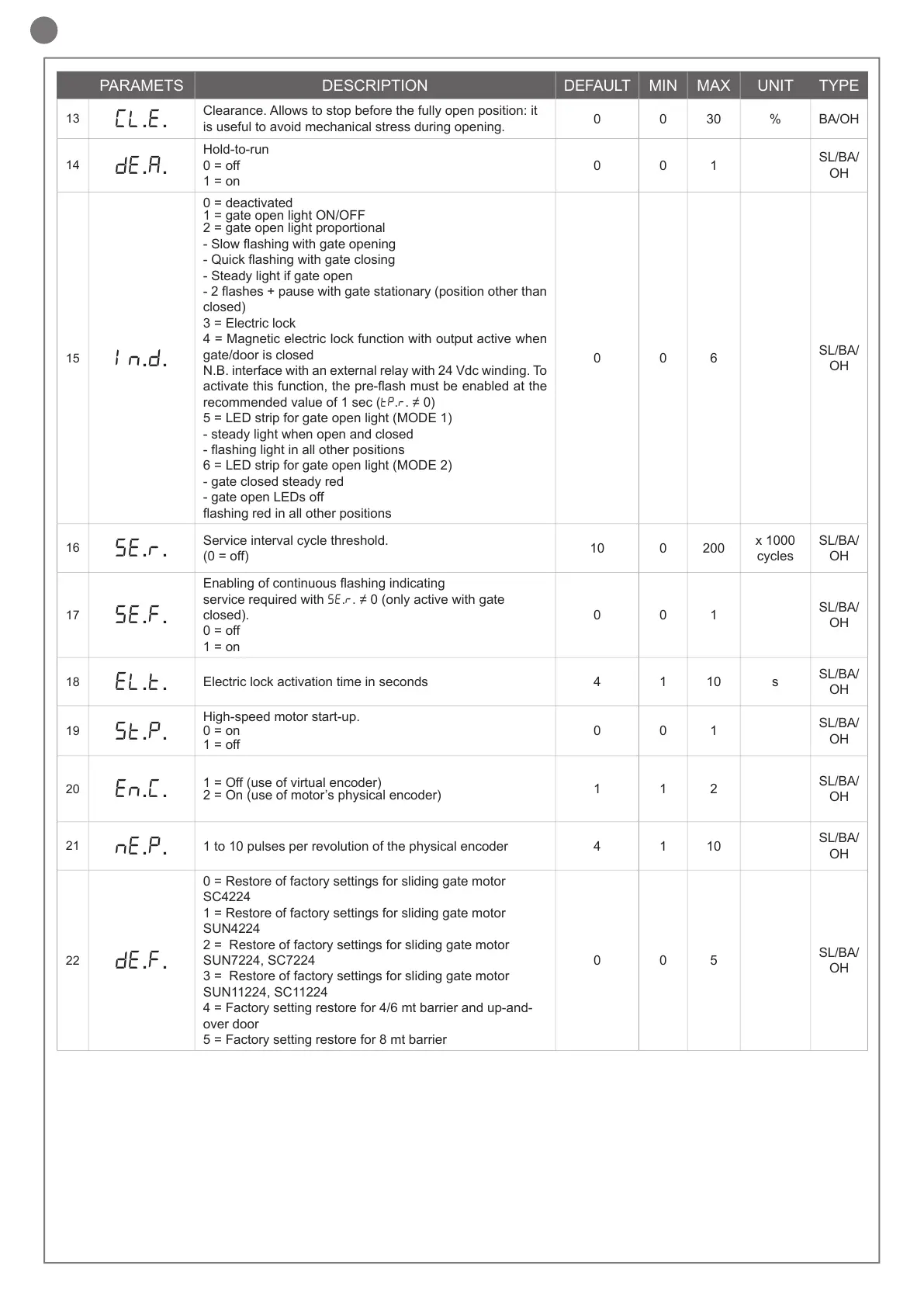

PARAMETS DESCRIPTION DEFAULT MIN MAX UNIT TYPE

13

CL.E.

Clearance. Allows to stop before the fully open position: it

is useful to avoid mechanical stress during opening.

0 0 30 % BA/OH

14

de.a.

Hold-to-run

0 = off

1 = on

0 0 1

SL/BA/

OH

15

IN.D.

0 = deactivated

1 = gate open light ON/OFF

2 = gate open light proportional

- Slow ashing with gate opening

- Quick ashing with gate closing

- Steady light if gate open

- 2 ashes + pause with gate stationary (position other than

closed)

3 = Electric lock

4 = Magnetic electric lock function with output active when

gate/door is closed

N.B. interface with an external relay with 24 Vdc winding. To

activate this function, the pre-ash must be enabled at the

recommended value of 1 sec (tP.r. ≠ 0)

5 = LED strip for gate open light (MODE 1)

- steady light when open and closed

- ashing light in all other positions

6 = LED strip for gate open light (MODE 2)

- gate closed steady red

- gate open LEDs off

ashing red in all other positions

0 0 6

SL/BA/

OH

16

se.r.

Service interval cycle threshold.

(0 = off)

10 0 200

x 1000

cycles

SL/BA/

OH

17

se.f.

Enabling of continuous ashing indicating

service required with se.r. ≠ 0 (only active with gate

closed).

0 = off

1 = on

0 0 1

SL/BA/

OH

18

EL.T.

Electric lock activation time in seconds 4 1 10 s

SL/BA/

OH

19

ST.P.

High-speed motor start-up.

0 = on

1 = off

0 0 1

SL/BA/

OH

20

EN.C.

1 = Off (use of virtual encoder)

2 = On (use of motor’s physical encoder)

1 1 2

SL/BA/

OH

21

NE.P.

1 to 10 pulses per revolution of the physical encoder 4 1 10

SL/BA/

OH

22

DE.F.

0 = Restore of factory settings for sliding gate motor

SC4224

1 = Restore of factory settings for sliding gate motor

SUN4224

2 = Restore of factory settings for sliding gate motor

SUN7224, SC7224

3 = Restore of factory settings for sliding gate motor

SUN11224, SC11224

4 = Factory setting restore for 4/6 mt barrier and up-and-

over door

5 = Factory setting restore for 8 mt barrier

0 0 5

SL/BA/

OH

and hold it down). A countdown should now appear: 49,48...,1 down

Loading...

Loading...