4 - INSTALLING THE PRODUCT

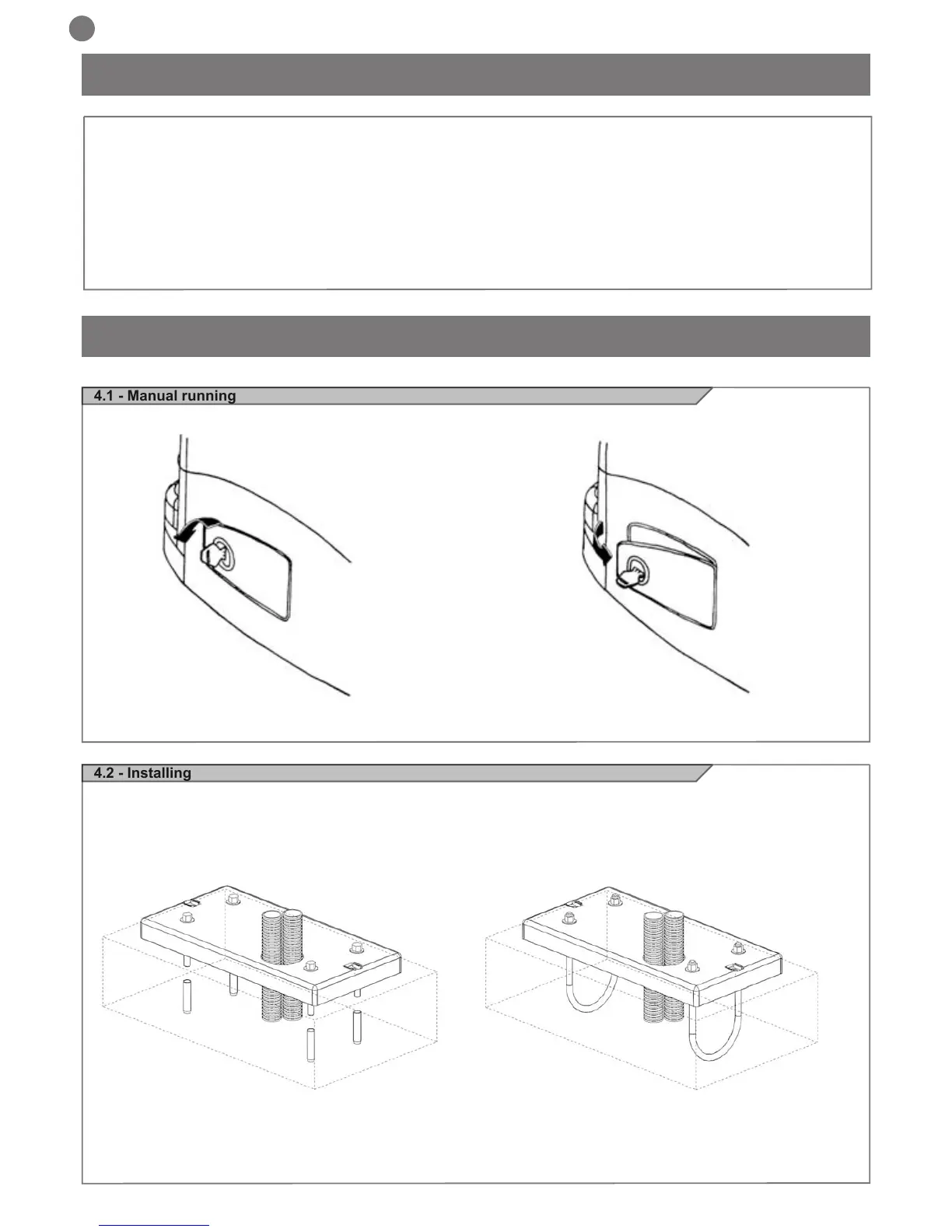

4.1 - Manual running

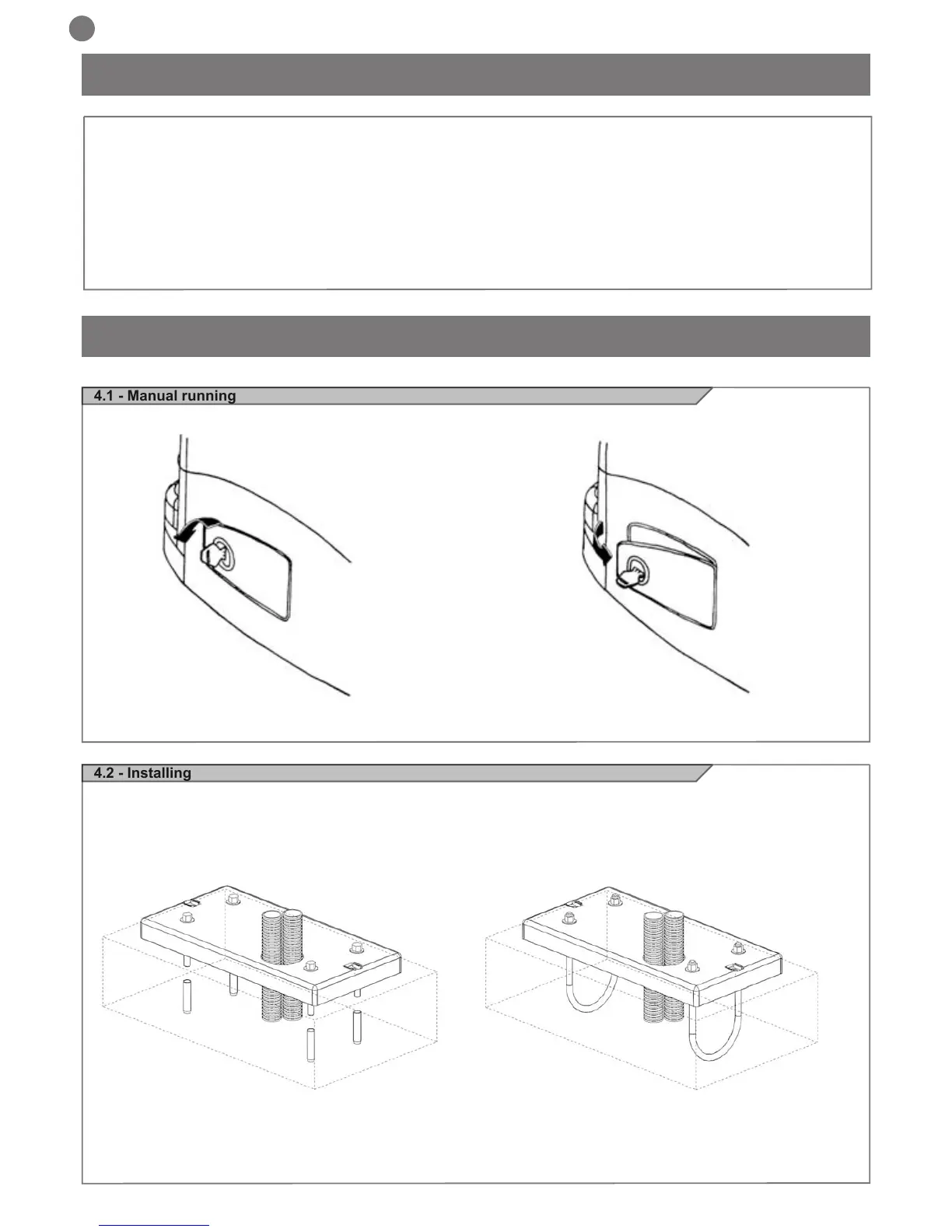

4.2 - Installing

3 - PRELIMINARY CHECKS

Before the installation starts, we suggest to carry out following

inspections and operations:

the gate framework must be strong and suitable;

the gate must not show too many sideways slide skids during the

running;

the system of wheels/lower rail and roller/upper runner must work

without too many frictions;

to avoid the gate derailment you must install the stop beats of the

sliding, whether at the opening or closing, and a second upper

roller/runner in full observance of the current law;

remove any manual lock in the beforehand gates;

take on the gate bottom the feed raceway of the feeding cables

(Ø25-50mm) and of external connection (photocell, ash-light, key

selector, etc...).

Insert the key and turn it 90° in anticlockwise direction.

Respecting the overall size, x to ground the base-plate through

4 sturdy screw-anchors (g.3) or drown it into the concrete (g.4).

N.B. The exact dimensions of the rack must be known to allow precise calculation of the counterplate position.

Pull the knob till it is perpendicular to the gearmotor.

Plan for one or more sheathing for the passage of the power lines.

Fig. 2

Fig. 3 Fig. 4

N.B. Take care to re-engage the gearmotor before starting it up. Engaging with the motor running may damage its internal components.

Loading...

Loading...