INTEGRAL BIT STORAGE TRAY

Conveniently located in the base of the Pillar Drill is a handy storage tray

for keeping your bits organised and close at hand. (Fig.19).

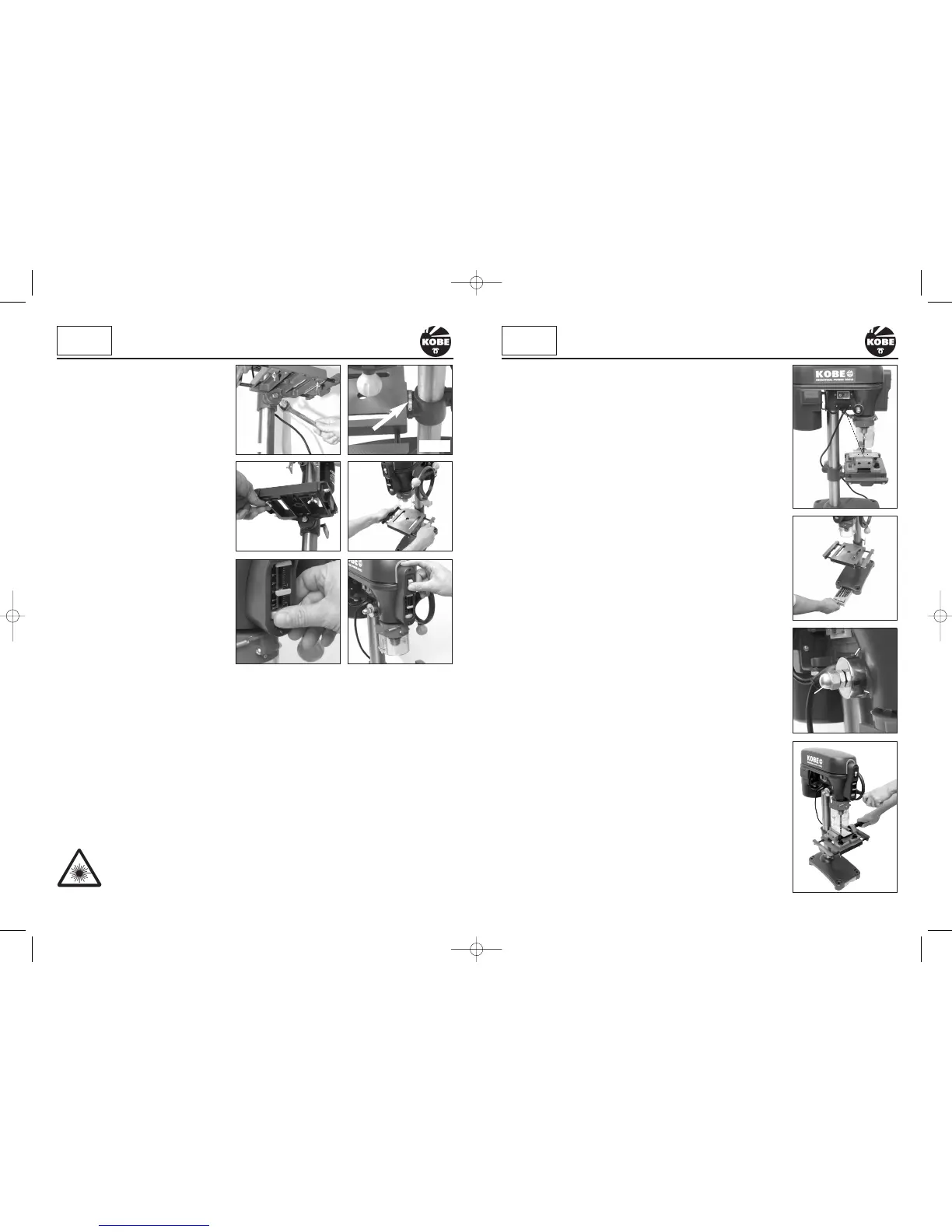

QUILL SPRING ADJUSTMENT

WARNING:

The quill spring is under extreme tension.

The quill spring is located in a chrome housing on the opposite side of the

feed shaft boss and returns the spindle to its uppermost position.

Adjustment is normally only required after many hours of use when it fails to

return the spindle to its uppermost position. With the spindle in its

uppermost position it can be seen that the chrome cover has a total of

three notches (Fig.20b) cut into the edge that align with the cast body of the

head stock. One of these notches is located over a cast peg (Fig. 20a) that

is part of the main casting.

WARNING: Before slackening the lock nuts ensure that the chrome

housing is held securely with a suitable grip or wrench. If not held

securely the quill spring will fully uncoil.

Carefully slacken the lock nuts (Fig.20c) only enough to allow the chrome

housing to be pulled out far enough to just clear the cast peg (Fig. 20a)

while holding the chrome cover with suitable grips. The spring is still under

tension and will try to uncoil as soon as it is released so be sure to resist

the torque. As soon as the chrome housing is able to clear the cast peg,

turn the chrome housing in an anti-clockwise direction until the next notch

locates onto the peg. While holding the chrome housing in this position

tighten the lock nuts. Do not over tighten otherwise you will damage the

chrome cover.

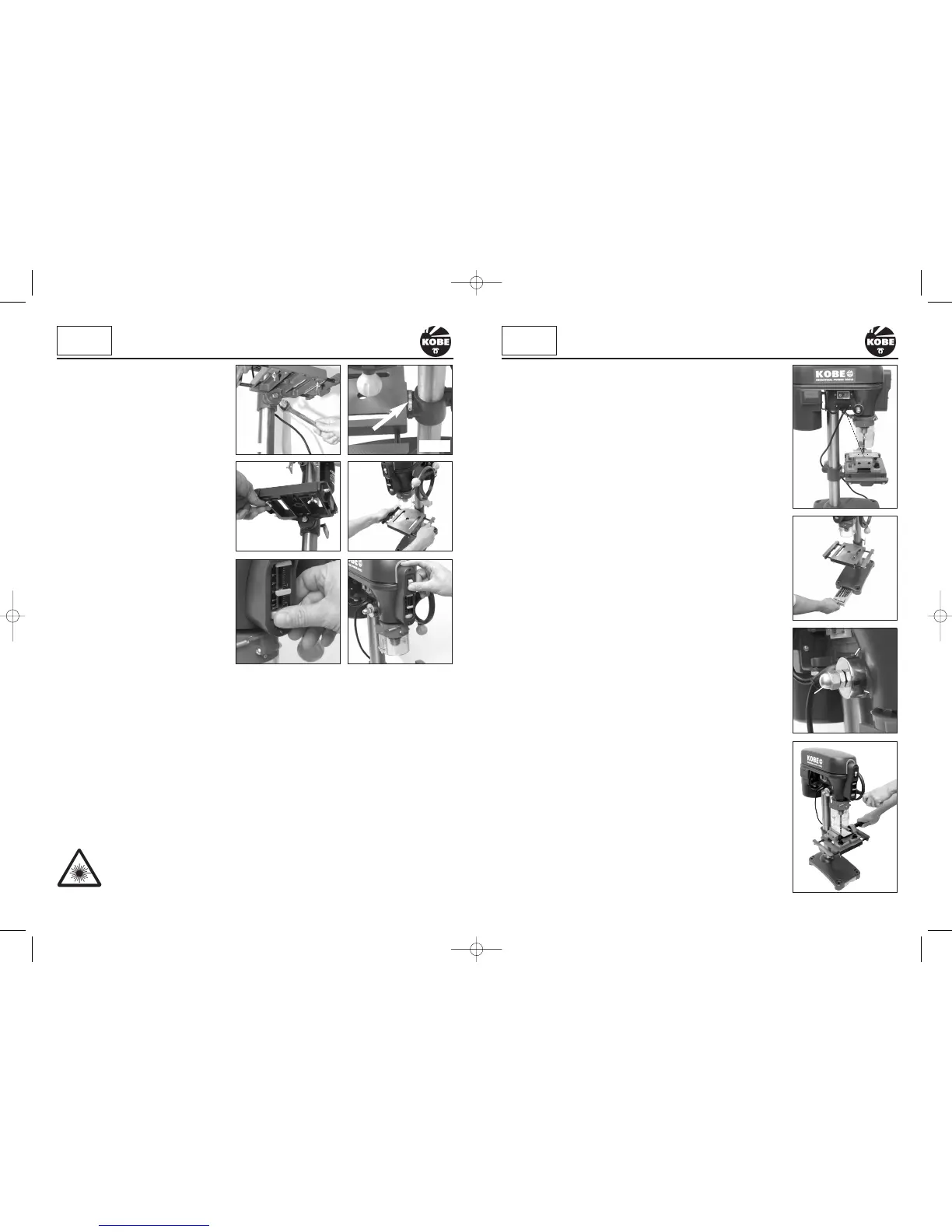

USING A MACHINE VICE

WARNING: The drill should never be used without the work piece being

securely held in a machine vice or clamped directly to the drill table.

The drill table is designed to accept a variety of machine vices which can be

fastened directly to the drill table; (Fig.21) gives an indication as to the type

of machine vice required.

Always secure the vice to the table with bolts, washers and nuts. If the drill

jams into the work piece, an unsecured machine vice will spin out of control

causing the drill to snap and possibly injure the operator.

ADJUSTING THE TABLE HEIGHT

To adjust the table height, slacken the

clamping lever at the rear of the table

support assembly (Fig. 5).

Slide the table up or down to desired

height. When the desired height has been

achieved, do not forget to re-secure the

clamping lever.

TILTING THE TABLE ± 45

°

Locate the securing bolt underneath the

table (Fig.12). With a suitable spanner or

wrench loosen the bolt. On the table

support assembly casting there is a

graduated 0 - 45° scale (Fig.13). Set the

table to the required angle and re-tighten

the bolt.

NOTE: The graduated scale is for guidance

only. We recommend the use of an

engineers protractor when setting any

angles

ADJUSTING THE TABLE WIDTH

Locate and loosen the wing nuts under the

table (Fig.14) and pull the side plates away from the main table (Fig.15). This will allow support for

larger machine vices and pieces of work (Fig.21). Once the side plates are in place don’t forget to

re-tighten the wing nuts.

SETTING THE DEPTH STOP

This facility is useful if a number of uniform depth holes are required in a work piece. The depth

stop is located on the front of the drilling head. To adjust, turn the thumb wheel (Fig.16) to the right

to increase the depth of travel of the drilling head or to the left to decrease the depth of travel.

LASER GUIDE

Located under the drilling head is a laser guide which is switched on using the on/off switch

located on the front of the drilling head above the depth stops (Fig.17). It provides target cross-

hairs (Fig.18) which once set on your first workpiece of a batch will facilitate the accurate

placement of subsequent pieces.

This Class 2 laser can potentially cause severe damage to eyes.

Never look directly into the laser beam or point the laser beam at people either

directly or indirectly through reflective surfaces.

8 9

Fig.14

Fig.16

Fig.15

Fig.20

Fig.19

KOBE

INDUSTRIAL

POWER TOOLS

SETTING UP & ADJUSTMENT

KOBE

INDUSTRIAL

POWER TOOLS

SETTING UP & ADJUSTMENT

Fig.12

Fig.13

Fig.17

Fig.18

20c

20a

20b

Fig.21

Loading...

Loading...