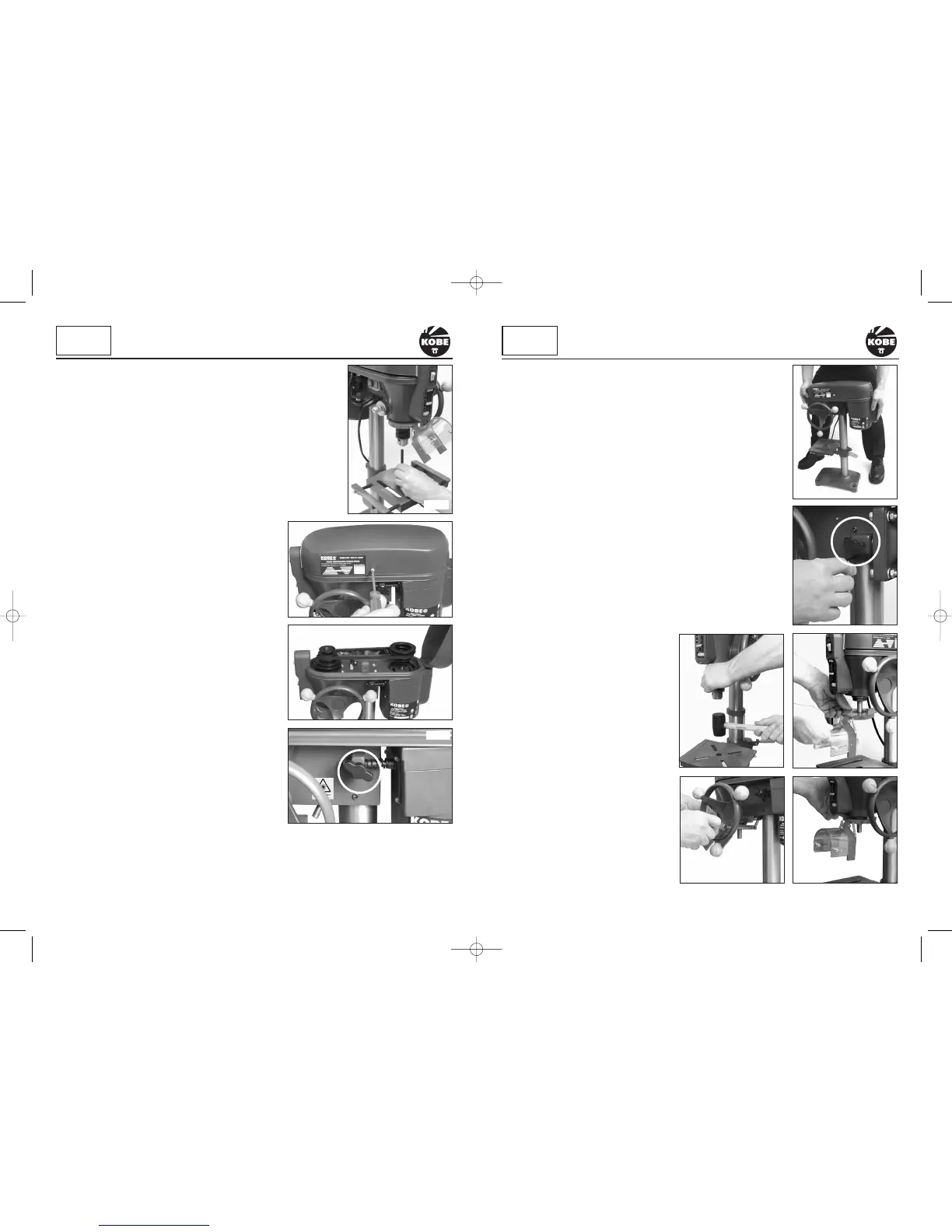

Fig.9

FITTING THE TABLE/SUPPORT ARM ASSEMBLY

Locate the table/support arm assembly (Fig.1) . Lower the table/

support arm assembly over the top of the column and line up with

the base plate. Tighten the support arm column clamp (Fig.5)

FITTING THE HEAD STOCK AND MOTOR ASSEMBLY

Locate the two grub screws in the side of the drill head stock and

motor assembly (Fig.7). Using a hexagonal key slacken the two grub

screws. Lift the drill head stock and motor assembly onto the

column. Make sure that it slides down and locates fully on the

column. Position the head stock and motor assembly, with the drill

head aligned over the table and base plate (Fig.6). Tighten the two

grub screws (Fig.7) to secure the head stock and motor assembly

into place. Retain the hexagon key for future adjustments.

FITTING THE CHUCK

The chuck has a taper fitting, simply place it onto the spindle adaptor

and tap with a soft rubber mallet (Fig.8). This is enough to secure in

it place and it should be tight enough. To make doubly sure, place a

piece of wood on the table and wind the manual feed handle to bring

the chuck down onto the wood pressing the chuck tighter onto the

spindle adaptor.

To remove, tap the chuck in a downward

motion with a soft mallet.

FITTING THE

TELESCOPIC GUARD

Position the clear plastic shield into the

red collar and secure in place with the two

small cross head screws. Place over the

chuck and locate onto the drill head collar

(Fig.9). Tighten the cross-head clamping

screw but don’t over tighten as this may

break the plastic body (Fig.10). Check that

the guard lifts easily and stays lifted to

change drills/cutting tools (Fig.11).

10

KOBE

INDUSTRIAL

POWER TOOLS

ASSEMBLY continued

7

Fig.6

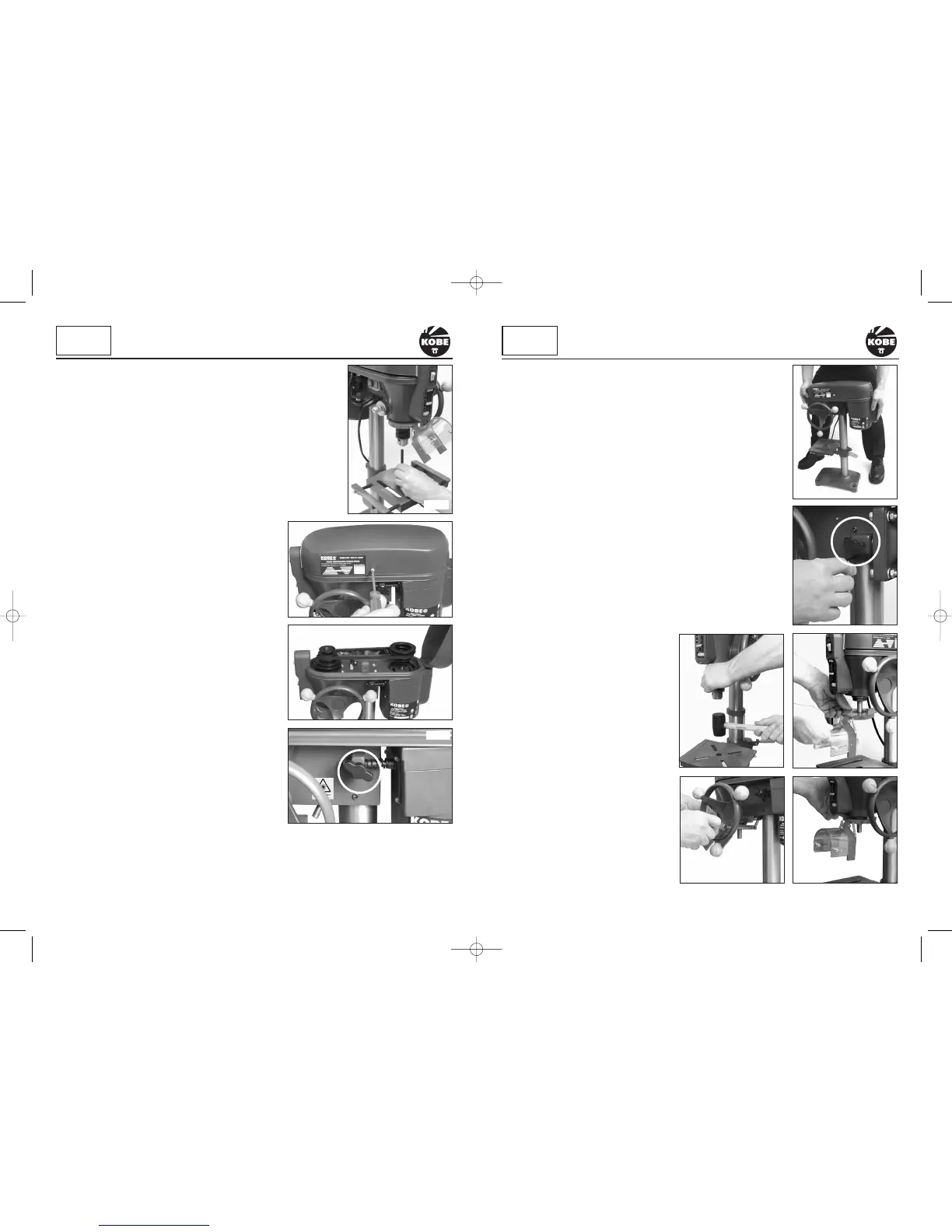

USING THE 3 JAW CHUCK

Select the drill bit required, open the jaws and insert the drill shank centrally

into the chuck (Fig. 22). Rotate the chuck by hand until the jaws grip the drill

bit. The chuck has three holes around the chuck body. Using the chuck key,

exert an even torque to tighten, moving from one hole to the next until all

three holes have been covered. Do not over tighten otherwise you will have

difficulty removing the drill bit.

CHANGING THE SPINDLE SPEED

Unscrew the cross head screw securing the pulley guard casing

(Fig.23). Lift open the casing to reveal the pulley system (Fig.24).

Determine the spindle speed required using (Fig.29) which shows

drill sizes against material types. Identify the pulley

arrangement that gives the nearest spindle speed to

that required by referring to the drill pulley

configurations (Fig. 28).

Slacken the wing nut located on the right side of the

drill head casting (Fig.25).

This will release the tension on the drive belt. The

motor, situated at the rear of the machine can now slide

on the slide bar. Push it towards the front to enable belts

to be removed and re-positioned to achieve your required

speed setting.

To move the drive belts to the desired pulley

arrangement. Push the belt on the largest drive spindle

pulley towards the next smallest pulley and at the

same time rotate the drive spindle by hand until the

drive belt locates onto the next smallest pulley (be

careful not to trap your fingers between the belt and

pulley). Repeat this procedure until the desired pulley

arrangement has been achieved.

BELT TENSION

When the desired pulley arrangement has been

achieved, tension the drive belt by inserting a large

screwdriver or small pry bar between the the drill head

casting and the motor mounting (Fig.26). Lever the

motor mount away from the casting and tighten the wing nut. To check that the correct tension

has been achieved, press your finger onto the centre of the drive belt (Fig.27). The drive belt

should move approximately 13mm. Once this has been achieved, re-tighten the wing nut to lock

the motor slide bar in position.

Fig.7

KOBE

INDUSTRIAL

POWER TOOLS

SETTING UP & ADJUSTMENT

Fig.8

Fig.11

Fig.10

Fig.23

Fig.24

Fig.22

Fig.25

KBE-271-2030K_Instructions.qxd 09/06/2009 09:20 Page 7

Loading...

Loading...