TP-6591 10/13 25Section 3 Scheduled Maintenance

3.3 Lubrication System

3.3.1 Oil Specifications

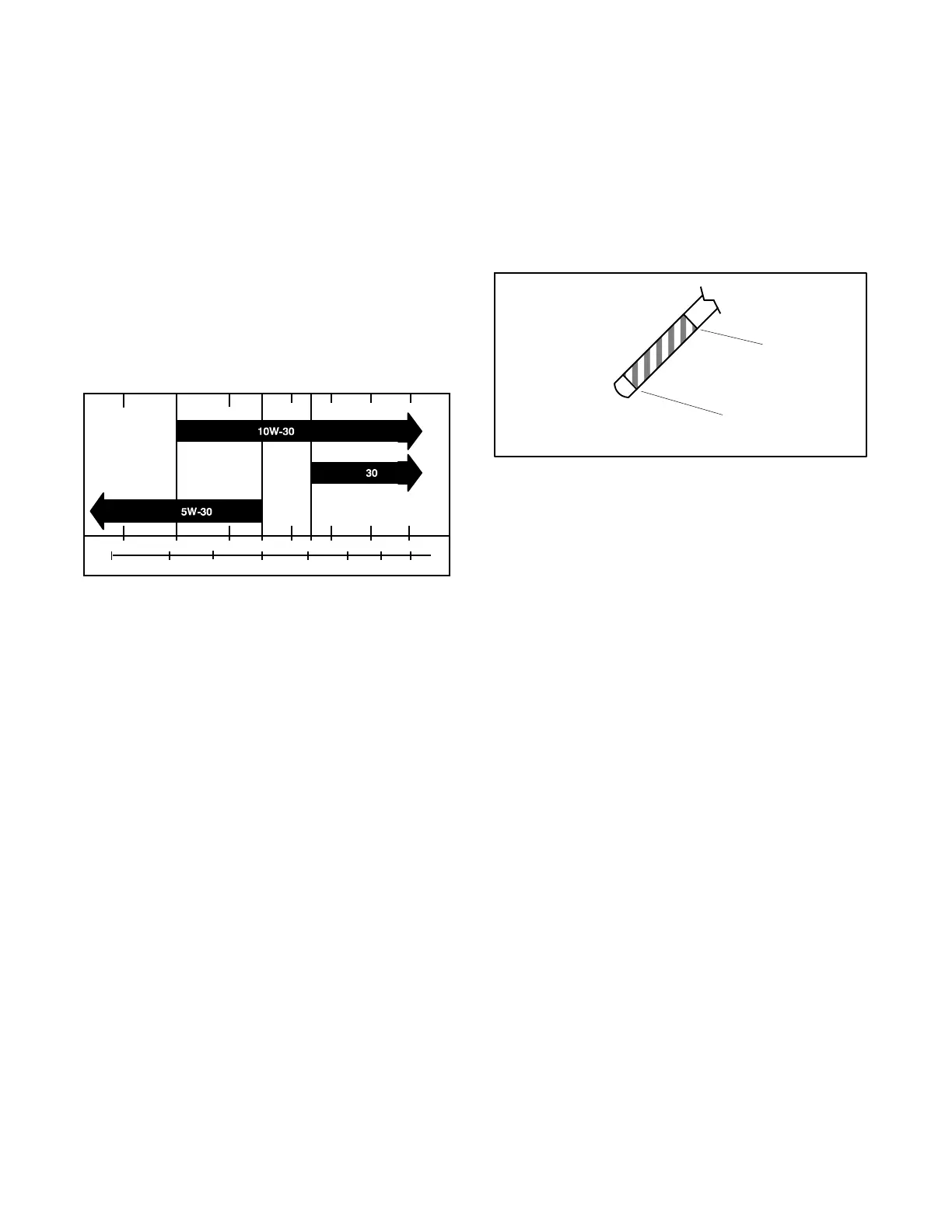

Use high-quality detergent oils (including synthetic) that

meets the American Petroleum Institute (API)

classification of SJ or higher. Using unsuitable oil or

neglecting an oil change may result in engine damage

that is not covered by the engine warranty. Figure 3-1

shows the recommended Society of Automotive

Engineers (SAE) viscosity designation for given

operating temperature ranges.

Do not mix different oil brands. Incompatibility could

cause a breakdown of lubricating ingredients and

reduce engine protection.

32 40 60 80 10020

F-20

C-30

-- 2 0 -- 1 0

0

10 20 30 40

Recommended SAE

iscosity Grades

SAE

0

50

Figure 3-1 Engine Oil Selection

3.3.2 Oil Check

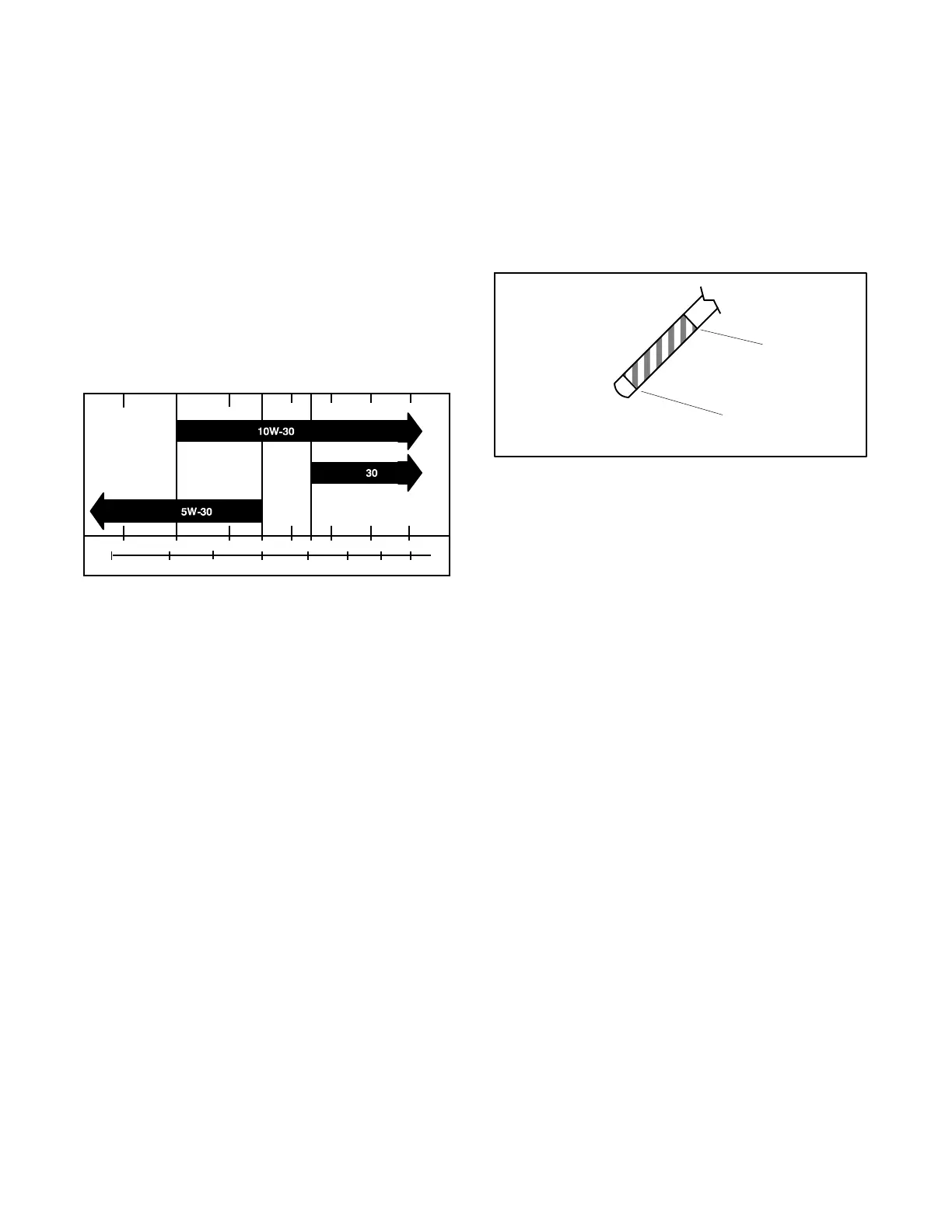

Check the oil level in the crankcase daily or before each

start-up to ensure that the level is in the safe range. Do

not check the oil level while operating the unit. Stop the

generator set and keep the generator set level to get an

accurate reading. To check the oil level, remove the

dipstick and wipe the end clean, reinsert and remove.

Maintain the oil level between the Full and Add marks on

the dipstick, as shown in Figure 3-2. See Section 1,

Service Views for the dipstick location.

1

TP-5586-3

2

1. Full mark

2. Add mark

Figure 3-2 Oil Level Check

Note: Do not operate the set if the oil level is below the

Add mark on the dipstick or above the Full mark

on the dipstick.

3.3.3 Oil Additions

Adding some oil between oil changes is normal. The

amount varies with generator set usage. Open the oil fill

cap and pour in a small amount of oil using a funnel or

other suitable pouring device. See Section 1, Service

Views for the oil check and oil fill locations.

Loading...

Loading...