9.11

Section 9

Inspection and Reconditioning

9

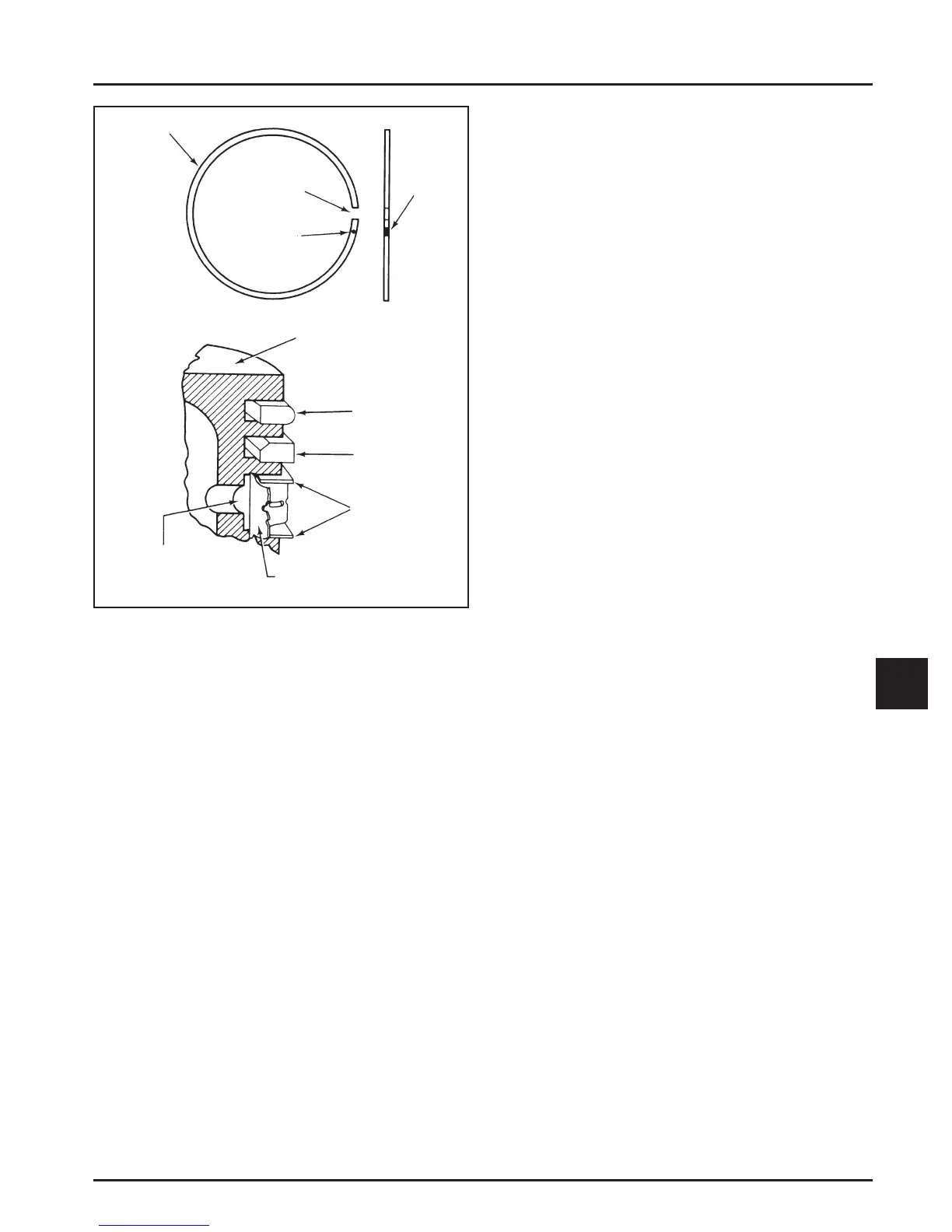

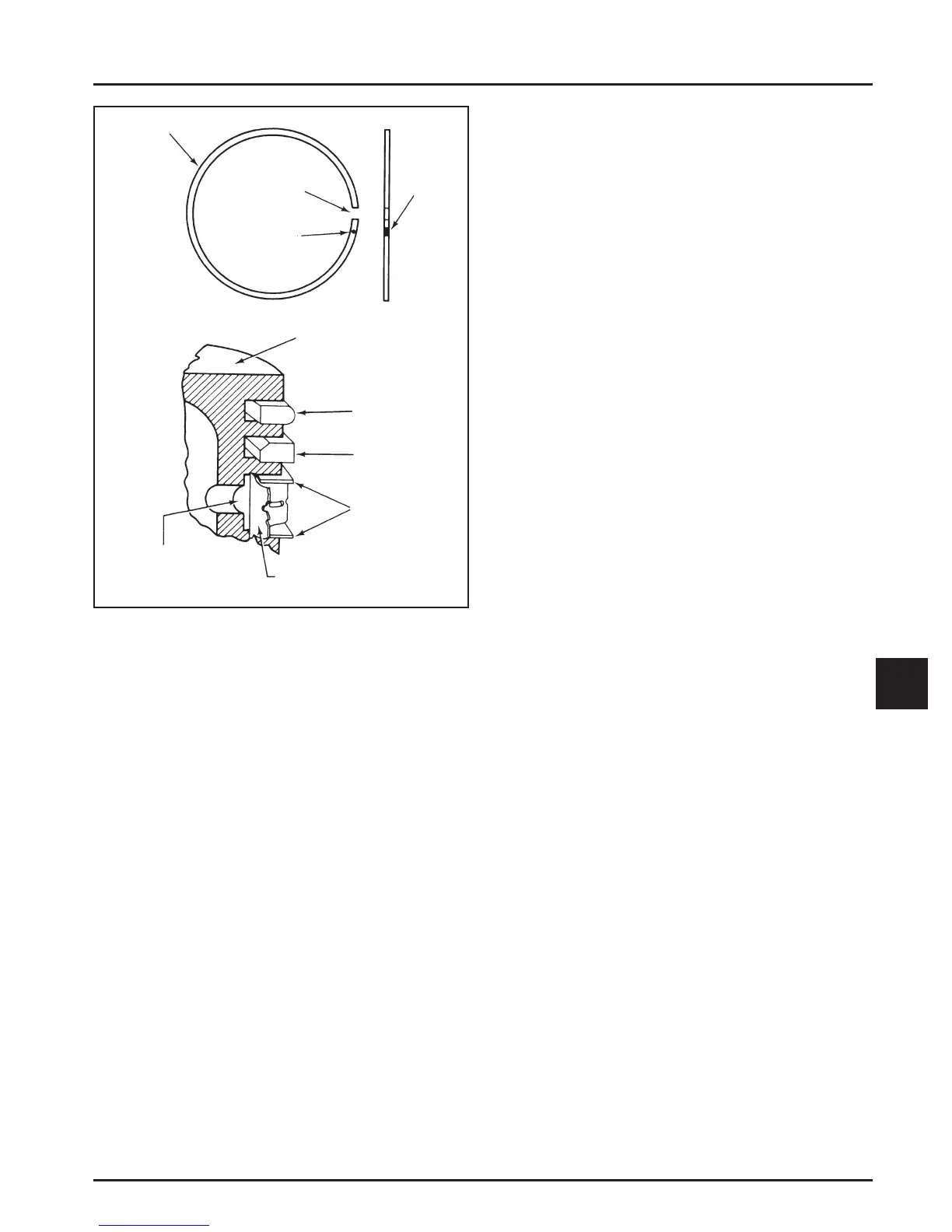

Piston Ring

End Gap

Identifi cation

Mark

Dykem

Stripe

Piston

Top

Compression

Ring

Center

Compression

Ring

Rails

Expander

Oil Control Ring

(Three-piece)

Figure 9-12. Piston Ring Installation.

1. Oil Control Ring (Bo om Groove): Install the

expander and then the rails. Make sure the ends

of expander are not overlapped.

2. Middle Compression Ring (Center Groove):

Install the center ring using a piston ring

installation tool. Make sure the identifi cation

mark is up or the dykem stripe (if contained) is to

the le of the end gap.

3. Top Compression Ring (Top Groove): Install the

top ring using a piston ring expender. Make sure

the identifi cation mark is up or the dykem stripe

(if contained), to the le of the end gap.

Connecting Rods

Off set, stepped-cap connecting rods are used in all

these engines.

Inspection and Service

Check the bearing area (big end) for excessive wear,

score marks, running and side clearances (refer to

Section 1, Specifi cations, Tolerances, and Special

Torque Values). Replace the rod and cap if scored or

excessively worn.

Service replacement connecting rods are available in

STD crankpin size and 0.25 mm (0.010 in.) undersize.

The 0.25 mm (0.010 in.) undersized rod can be

identifi ed by the drilled hole located in the lower end

of the rod shank. Always refer to the appropriate parts

information to ensure that correct replacements are

used.

Hydraulic Lifters

Inspection

Check the base surface of the hydraulic li ers for wear

or damage. If the li ers need to be replaced, apply a

liberal coating of Kohler lubricant (see Section 2) to

the base of each new li er before it is installed.

“Bleeding” the Lifters

To prevent a possible bent push rod or broken rocker

arm, it is important to bleed any excess oil out of the

li ers before they are installed.

1. Cut a 50-75 mm (2-3 in.) piece from the end of an

old push rod and chuck it in a drill press.

2. Lay a rag or shop towel on the table of the drill

press and place the li er, open end up, on the

towel.

3. Lower the chucked push rod until it contacts the

plunger in the li er. Slowly pump the plunger

two or three times to force the oil out of the feed

hole in the side of the li er.

Loading...

Loading...