SECTION

6-

ELECTRICAL SYSTEMS &

COMPONENTS

BATTERY

IGNITION

SYSTEM

These

engines

use

a

battery

ignition

system,

which

uses

the

electrical

charge

stored

in

the

battery

to

induce

a

high

voltage

in

the

ignition

coil.

This

high

voltage

is

impressed

across

the

spark

plugs

where

it

jumps

the

gaps

producing

the

spark

that

ignites

the

air-fuel

mixture

in

the

cylinders.

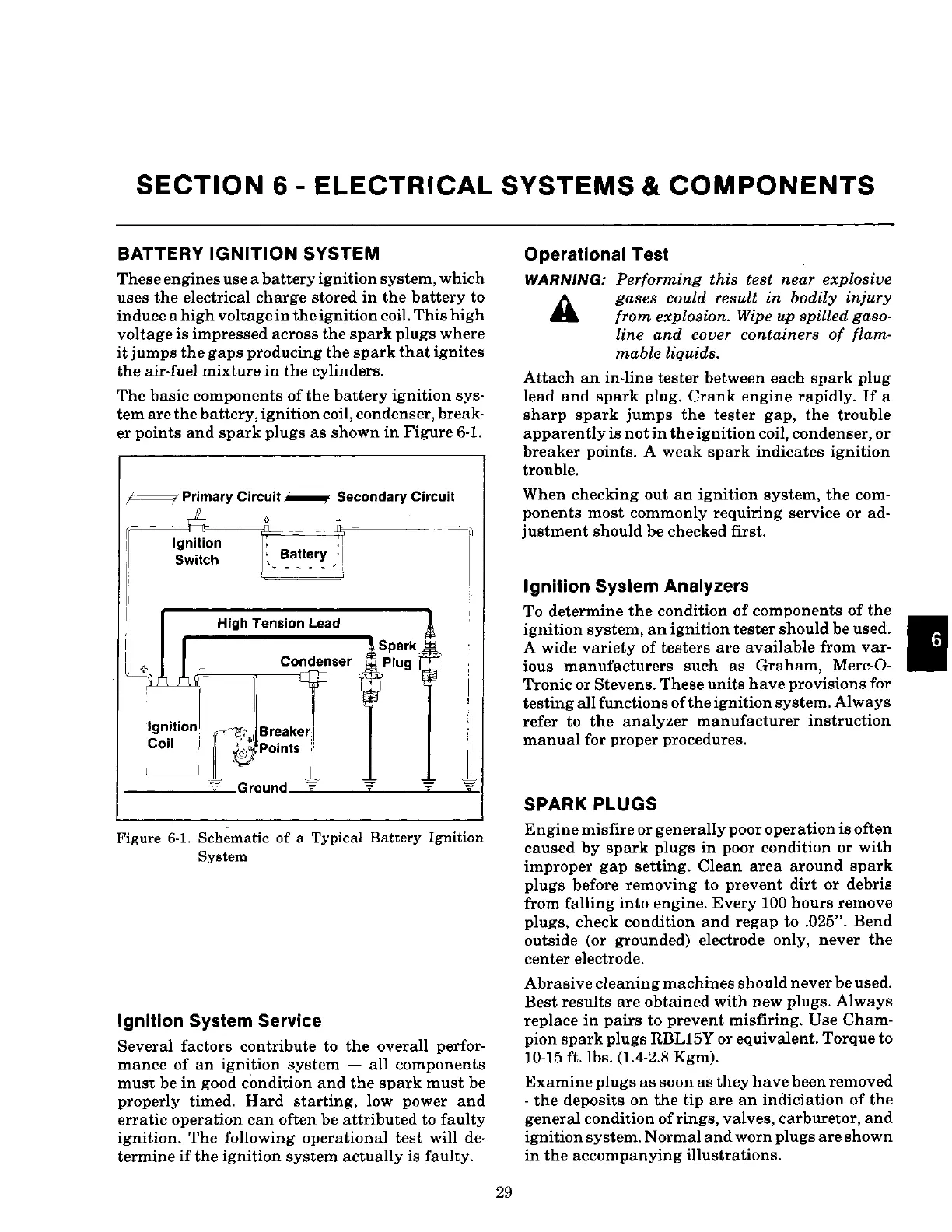

The

basic

components

of

the

battery

ignition

sys-

tem

are

the

battery,

ignition

coil, condenser, break-

er

points

and

spark

plugs

as

shown

in

Figure

6-1.

F Primary

Circuit.........,.

Secondary

Circuit

rF

--~--

0

~

~

II

----,,

1

lgnilion

,

:II

Switch ' Battery ·

"~

-~--:-

~

- : i

.

High

Tension Lead 4

11

!Spark,&

I

~

~

Co~~nser

ePiug

w

lgn_ilioJ ["TI',, Breaker

1

1 l

Co1l

: 1

~

Poinls

1

-------''~c_Ground

=

-=-

Figure 6-1.

Schematic

of

a Typical Battery Ignition

System

Ignition System Service

Several

factors

contribute

to

the

overall

perfor-

mance

of

an

ignition

system

-

all

components

must

be

in

good

condition

and

the

spark

must

be

properly

timed.

Hard

starting,

low power

and

erratic

operation

can

often

be

attributed

to

faulty

ignition.

The

following

operational

test

will de-

termine

if

the

ignition

system

actually

is

faulty.

29

Operational Test

WARNING:

Performing

this

test

near

explosive

gases

could result

in

bodily

injury

from explosion. Wipe up spilled gaso-

line

and

cover containers

of

flam-

mable

liquids.

Attach

an

in-line

tester

between

each

spark

plug

lead

and

spark

plug.

Crank

engine

rapidly.

If

a

sharp

spark

jumps

the

tester

gap,

the

trouble

apparently

is

no

tin

the

ignition

coil,

condenser,

or

breaker

points.

A

weak

spark

indicates

ignition

trouble.

When

checking

out

an

ignition

system,

the

com-

ponents

most

commonly

requiring

service

or

ad-

justment

should

be

checked first.

Ignition System Analyzers

To

determine

the

condition

of

components

of

the

ignition

system,

an

ignition

tester

should

be

used.

A wide

variety

of

testers

are

available

from

var-

ious

manufacturers

such

as

Graham,

Merc-0-

Tronic

or

Stevens.

These

units

have

provisions

for

testing

all

functions

of

the

ignition

system.

Always

refer

to

the

analyzer

manufacturer

instruction

manual

for

proper

procedures.

SPARK PLUGS

Engine

misfire

or

generally

poor

operation

is

often

caused

by

spark

plugs

in

poor

condition

or

with

improper

gap

setting.

Clean

area

around

spark

plugs

before

removing

to

prevent

dirt

or

debris

from

falling

into

engine.

Every

100

hours

remove

plugs,

check

condition

and

regap

to

.025".

Bend

outside (or grounded) electrode only,

never

the

center

electrode.

Abrasive

cleaning

machines

should

never

be

used.

Best

results

are

obtained

with

new

plugs.

Always

replace

in

pairs

to

prevent

misfiring.

Use

Cham-

pion

spark

plugs

RBL15Y

or

equivalent.

Torque

to

10-15 ft. lbs. (1.4-2.8 Kgm).

Examine

plugs

as

soon

as

they

have

been

removed

-

the

deposits

on

the

tip

are

an

indiciation

of

the

general

condition

of

rings,

valves,

carburetor,

and

ignition

system.

Normal

and

worn

plugs

are

shown

in

the

accompanying

illustrations.