1110

STEERING SYSTEM

PCCS, joystick controlled, wet multiple-disc steering clutches are

spring-loaded and hydraulically released. Wet multiple-disc,

pedal/lever controlled steering brakes are spring-actuated

hydraulically released and require no adjustment. Steering clutches

and brakes are interconnected for easy, responsive steering.

Minimum turning radius. . . . . . . . . . . . . . . . . . . . . . . . . . 4.2 m 13'9"

UNDERCARRIAGE

Suspension . . . . . . . . . . . . . Oscillating equalizer bar and pivot shaft

Tr ack roller frame. . . . . . . . . . . . . . . Cylindrical, high-tensile-strength

steel construction

Rollers and idlers. . . . . . . . . . . . . . . . . . . . . . Lubricated track rollers

K-Bogie undercarriage

Lubricated track rollers are resiliently mounted to the track

frame with a bogie suspension system whose oscillating motion

is cushioned by rubber pads.

Extreme service track shoes

Lubricated tracks. Unique seals prevent entry of foreign

abrasives into pin to bushing clearances to provide extended

service life. Track tension is easily adjusted with grease gun.

Number of shoes (each side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Grouser height:

Single grouser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93 mm 3.7"

Shoe width (standard) . . . . . . . . . . . . . . . . . . . . . . . . . . 610 mm 24"

Ground contact area . . . . . . . . . . . . . . . . . . . . . 48560 cm

2

7,527 in

2

Ground pressure (tractor) . . . . . . . . . . 108 kPa 1.10 kg/cm

2

15.6 psi

Number of track rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Number of carrier rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

COOLANT AND LUBRICANT

CAPACITY (REFILL)

Fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . .1200 ltr 317.0 U.S. gal

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120 ltr 31.7 U.S. gal

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86 ltr 22.7 U.S. gal

Torque converter, transmission,

bevel gear, and steering system . . . . . . . . .150 ltr 39.6 U.S. gal

Final drive (each side) . . . . . . . . . . . . . . . . . . . .65 ltr 17.1 U.S. gal

Extreme Additional Ground Ground

service shoes weight contact area pressure

710 mm 680 kg 56520 cm

2

126 kPa

1.28 kgf/cm

2

28" 1,500 lb 8,760 in

2

18.2 psi

810 mm 1360 kg 64480 cm

2

111 kPa

1.13 kgf/cm

2

32" 3,000 lb 9,990 in

2

16.0 psi

ENGINE

Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Komatsu SAA6D170E-5

Type. . . . . . . . . . . . . . . . . . . . . 4-cycle, water-cooled, direct injection

Aspiration. . . . . . . . Turbocharged, air-to-air aftercooled, cooled EGR

Number of cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Bore x stroke . . . . . . . . . . . . . . . . . 170 mm x 170 mm 6.69" x 6.69"

Piston displacement . . . . . . . . . . . . . . . . . . . . . . . 23.15 ltr 1,413 in

3

Governor . . . . . . . . . . . . . . . . . . All-speed and mid-range, electronic

Horsepower

SAE J1995 . . . . . . . . . . . . . . . . . . . . . . . . Gross 474 kW 636 HP

ISO 9249 / SAE J1349* . . . . . . . . . . . . . . . . . Net 455 kW 610 HP

Rated rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1800 rpm

Fan drive type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydraulic

Lubrication system

Method . . . . . . . . . . . . . . . . . . . . . . . Gear pump, force lubrication

Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Full-flow

*Net horsepower at the maximum speed of

radiator cooling fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

433 kW 580 HP

TORQFLOW TRANSMISSION

Komatsu TORQFLOW transmission consists of a water-cooled,

3-element, 1-stage, 1-phase torque converter with lockup clutch

and a planetary gear, multiple-disc clutch transmission which is

hydraulically actuated and force-lubricated for optimum heat

dissipation. Gearshift lock lever and neutral safety switch

prevent accidental starts.

FINAL DRIVES

Double-reduction final drive of spur and planetary gear sets to

increase tractive effort and reduce gear tooth stresses for long final

drive life. Segmented sprocket teeth are bolt-on for easy replacement.

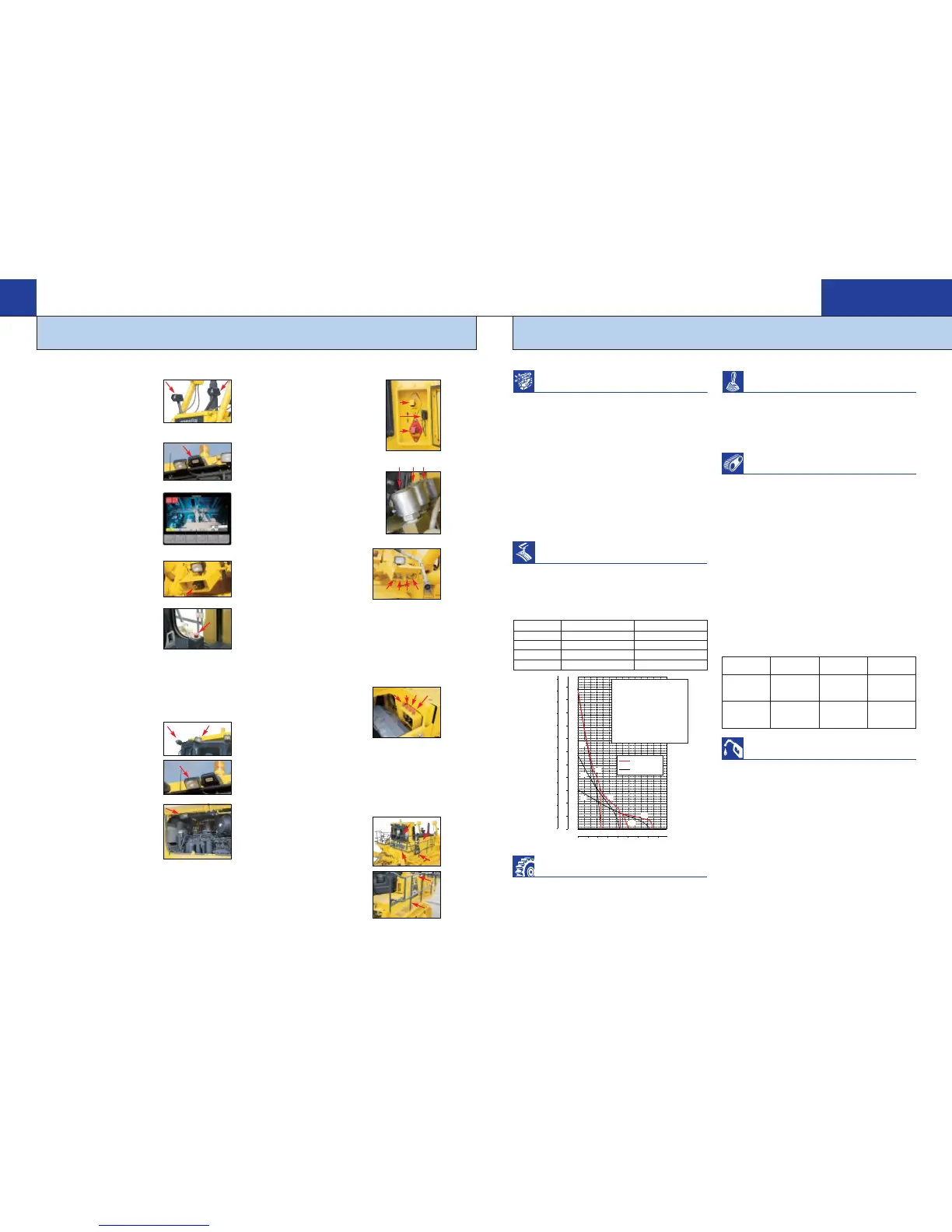

Gear Forward Reverse

1st 3.5 km/h 2.2 mph 4.6 km/h 2.9 mph

2nd 6.8 km/h 4.2 mph 8.9 km/h 5.5 mph

3rd L 8.0 km/h 5.0 mph 9.7 km/h 6.0 mph

3rd 11.8 km/h 7.3 mph 15.8 km/h 9.8 mph

D375A-6

Power Shift

DRAWBAR PULL VS. SPEED

MAXIMUM USABLE PULL

DEPENDS ON TRACTION AND

WEIGHT OF TRACTOR

INCLUDING MOUNTED

EQUIPMENT

S

PECIFICATIONS

D375A

-6

CRAWLER DOZER

D375A-6 C RAWLER D OZER

N

EW

S

AFETY &

M

AINTENANCE

F

EATURES

Highly mounted headlights

Illuminate the places in front of the

machine more effectively. Use of HID

lamps allows for performing night

works more safely.

Uninterrupted power source *

Uninterrupted power source allows for 2-way radio

communication at any time. Interior lights can be turned on

with the starting switch at OFF position. (The lights do not

work with the opening/closing of the cab door.)

Access lights *

Access lights are installed at two

places (the right and left) of the front

and at one place of the rear of the

machine for safe getting on/off and

servicing at night.

Working light for the engine bay *

A working light is installed inside the

engine hood (left side) to facilitate

night-time inspection and

maintenance.

Isolator box *

Battery isolator and starting motor isolator are housed in the

isolator box on the left side of the machine to facilitate cut-off

of the battery circuit for the maintenance of the machine.

Rear view camera

Allows the operator to see the rear

view image sent from it on the

monitor. (Be sure to check the safety

around the machine with your eyes.

The rear view camera is a mere

supplement device to check the rear

safety.)

Manual emergency engine

shutdown switches *

In case you urgently need to stop the

engine, use either of the two switches

installed in the cab and at the rear

right of the machine. (Do not use the

switches for normal engine stop.)

Provision for platform *

Provision for platform eliminates the need to modify the

machine for installation of platform.

Platform with handrails and toe

boards

Platform gives access to the side

faces and the rear of the machine.

Check and refilling of fuel and

hydraulic oil, cleaning of cab window

glass, check of cab lights, etc. can be

performed with ease.

Canister-type breather *

Canister-type breathers are remotely

arranged inside the left exterior cover to

facilitate check and cleaning of the

breather of each component.

A : Power train case B : Flywheel housing

C : Damper case

Evacuation service center *

Couplings (made by Wiggins)

installed at the rear left of the

machine allows for quick drain and

charge of oil and coolant. The service

center eliminates the need to get on/off the machine and to

remove/install covers for the work, and realizes safe and

quick servicing.

A : Engine oil B : Radiator coolant

C : Transmission oil D : Hydraulic oil

Concentrated sampling points *

Concentrated sampling points are

remotely arranged in the right storage

for the tool box to facilitate sampling

of the oil and coolant from each

component.

A : Engine oil B : Radiator coolant

C : Transmission oil D : Hydraulic oil

ABC

BACD

BDAC

Rear view camera

Camera image

Switch location (at the rear)

Switch location (inside the cab)

Jump-start connectors are also provided

in the box in case the batteries run out.

A : Starter isolator B : Batteries isolator

C : Jump start receptacle

A

B

C

Komatsu designs our bulldozers with safety in mining operations. Following safety features are optionally available for D375A-6.

Safety features marked with * are standard equipment for D375A-6 with mining specification.

Loading...

Loading...