ENGLISH

11

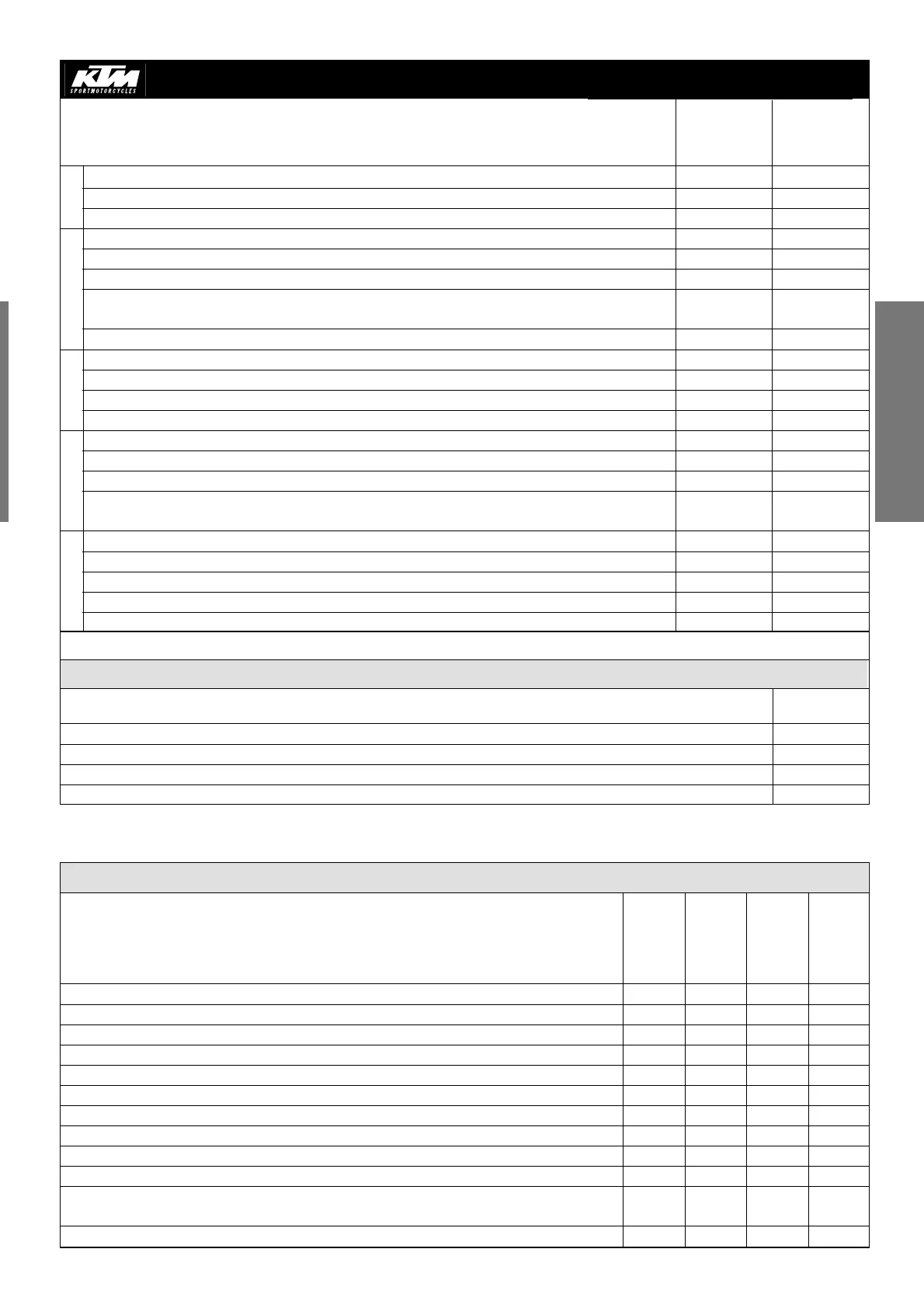

PERIODIC MAINTENANCE

service

every

10 hours

at least

once a year

MAINTENANCE WORK DONE BY KTM AUTHORISED WORKSHOPS IS NOT A SUBSTITUTE OF CARE AND CHECKS DONE BY THE RIDER!

A washed motorcycle can be checked more quickly which saves money!

Check transmission oil level ●

Change transmission oil ●

Check spark plug, change it if necessary, set electrode gap ●

Check carburetor for tight fit at intake flange ●

Check idle setting when engine is warm ●

Check exhaust system for leaks and suspension ●

Check actuating cables for damage, smooth operation, and kink-less ●

arrangement, adjust and lubricate

Clean air filter and air filter box ●

Check lining thickness of brake shoes ●

Check brake drums ●

Check/adjust smooth operation, free travel of handbrake levers ●

Check screws of brake system for tight fit ●

Check suspension strut and fork for leaks and proper function ●

Check swinging-fork pivot ●

Check/adjust steering-head bearing ●

Check all chassis screws for tight fit (fork plates, axle nuts, swinging-fork pivot, ●

suspension strut)

Check spoke tension and rim join ●

Check tire condition and inflation pressure ●

Check chain, chain wheels, chain wheel guides for wear, tight fit, and tension ●

Lubricate chain ●

Check wheel bearings for play ●

IMPORTANT RECOMMENDED MAINTENANCE PROCEDURES TO BE PERFORMED BASED ON A SEPARATE SUPPLEMENTARY ORDER

Drain and clean the carburetor's float chamber ●

Perform complete fork maintenance ●

Clean and lubricate the steering-head bearing ●

Clean and lubricate the swinging-arm bearing ●

WHEELS CHASSIS BRAKES ADD-ON-PARTS

ENGINE

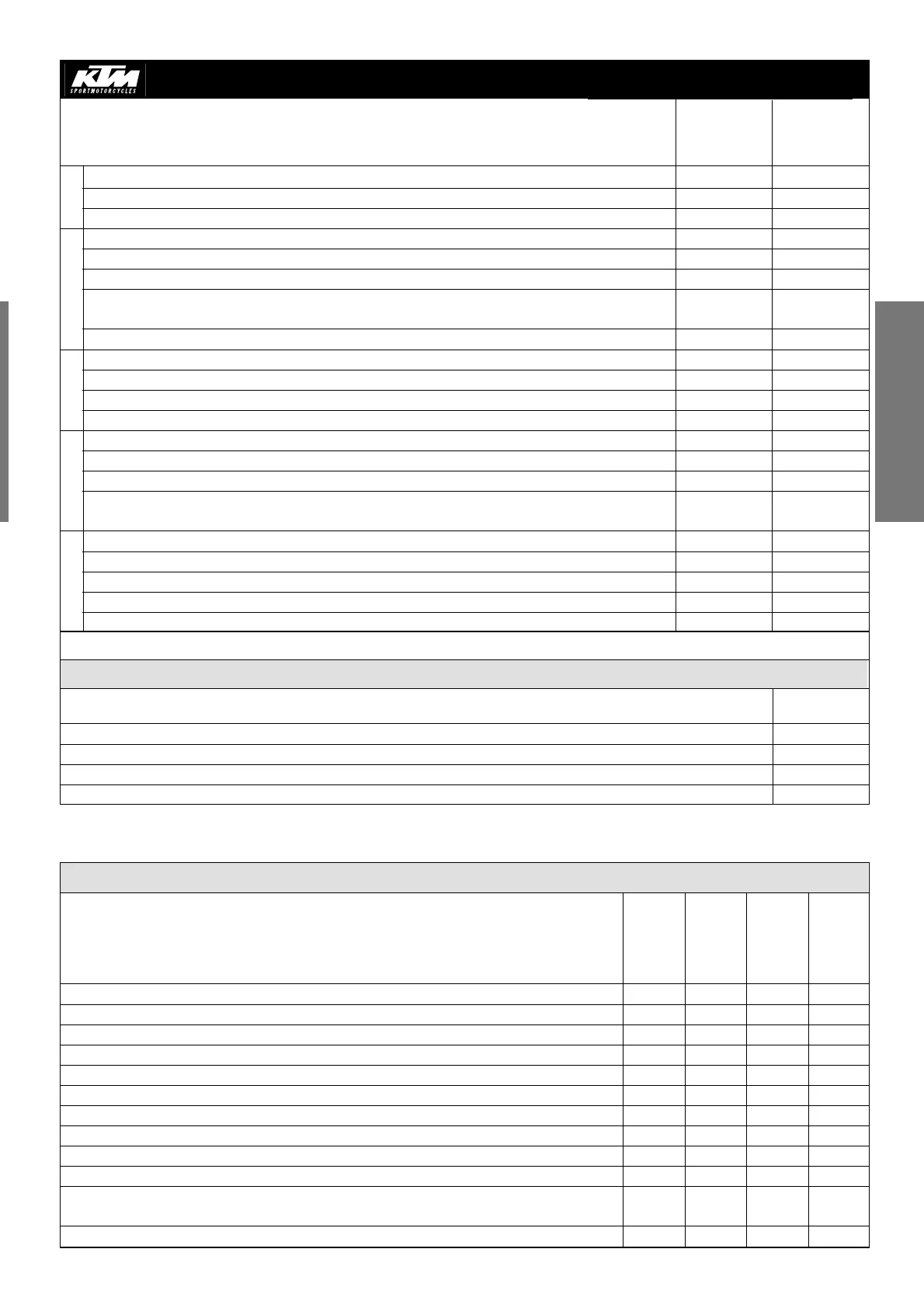

50 ccm MINIS

AIR-COOLED

at least

once a year

VITAL CHECKS AND CARE PROCEDURES TO BE CONDUCTED BY THE OWNER OR THE MECHANIC

Check transmission oil level ●

Lubricate and adjust actuating cables and nipples ●

Remove and clean dust sleeves of telescopic fork in regular intervals ●

Clean and lubricate chain, check tension and readjust it if necessary ●●

Clean air filter and filter box ●

Check tire inflation pressure and wear ●

Check fuel lines for leaks ●

Drain and clean float chamber ●

Verify smooth operation of all controls ●

Check brake performance ●●

Treat exposed metal components (except for the exhaust system) with wax-based ●

anti-corrosion a

gents

Check all screws, nuts, and hose clamps for their tight fit in regular intervals ●

for cross

country use

once a year

after every

cleaning

before each

start

Loading...

Loading...