19PERIODIC SERVICE

ENGLISH

*At 1.013 x 10 Pa (760 mmHg) pressure

(atmospheric). A higher boiling point is obtained by

using a radiator pressure cap which permits the

development of pressure within the cooling system.

5. Adding the LLC

(1) Add only water if the coolant level reduces in the

cooling system by evaporation.

(2) If there is a coolant leak, add the LLC of the same man-

ufacturer and type in the same coolant percentage.

*Never add any long-life coolant of different manufactur-

er. (Different brands may have different additive compo-

nents, and the engine may fail to perform as specified.)

6. When the LLC is mixed, do not employ any radiator

cleaning agent. The LLC contains anti-corrosive

agent. If mixed with the cleaning agent, sludge may

build up, adversely affecting the engine parts.

7. Kubota's genuine long-life coolant has a service life

of 2 years. Be sure to change the coolant every 2

years.

A The above data represent industry standards that

necessitate a minimum glycol content in the

concentrated anti-freeze.

BRadiator cement

As the radiator is solidly constructed, there is little

possibility of water leakage. Should this happen,

however, radiator cement can easily fix it. If leakage is

serious, contact your local KUBOTA dealer.

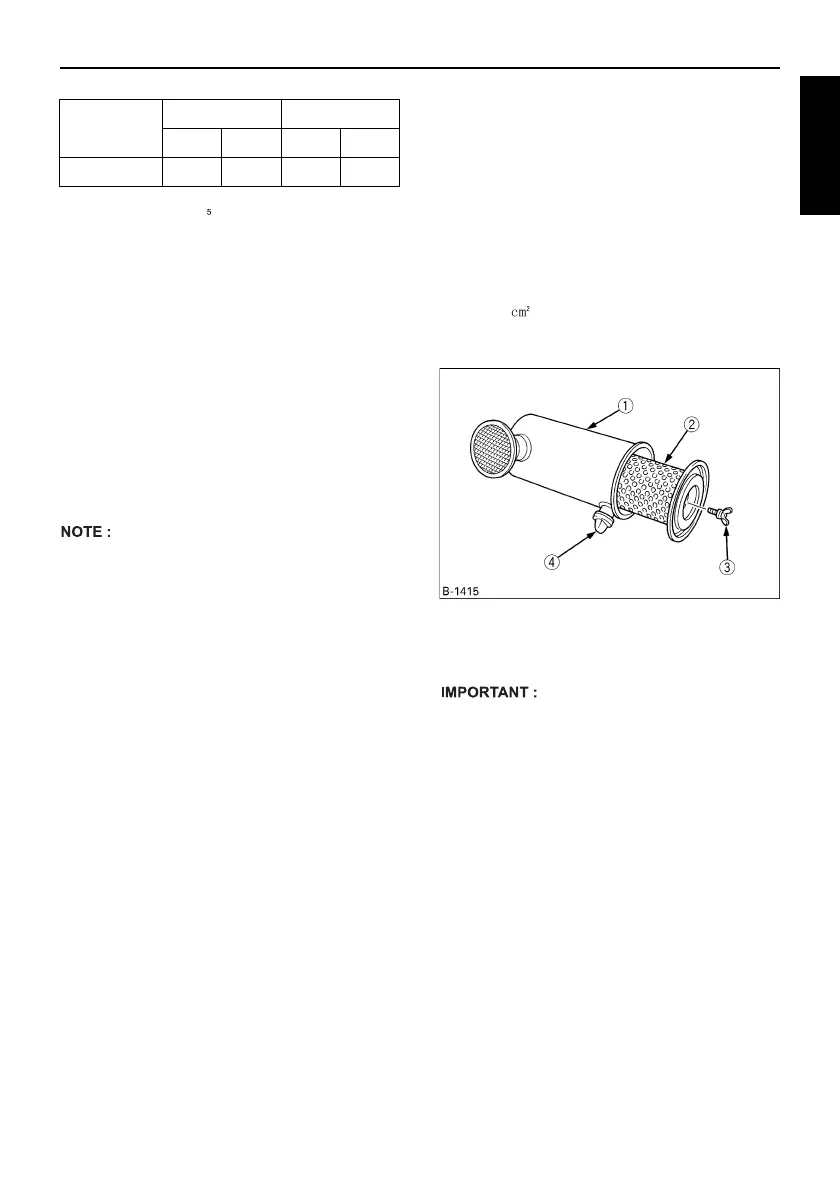

AIR CLEANER

Since the air cleaner employed on this engine is a dry

type, never apply oil to it.

1. Open the evacuator valve once a week under

ordinary conditions - or daily when used in a dusty

place. This will get rid of large particles of dust and

dirt.

2. Wipe the inside air cleaner clean with cloth if it is dirty

or wet.

3. Avoid touching the element except when cleaning.

4. When dry dust adheres to the element, blow

compressed air from the inside turning the element.

Pressure of compressed air must be under 205 kPa

(2.1 kgf/ , 30 psi).

5. Replace the element every year or every 6

cleanings.

A Make sure the wing bolt for the element is tight

enough. If it is loose, dust and dirt may be sucked in,

wearing down the cylinder liner and piston ring

earlier and thereby resulting in poor power output.

A Do not overservice the air cleaner element.

Overservicing may cause dirt to enter the engine

causing premature wear. Use the dust indicator as a

guide on when to service.

Vol %

Anti-freeze

Freezing Point Boiling Point *

°C °F °C °F

50 -37 -34 108 226

(1) Air cleaner body

(2) Element

(3) Wing bolt

(4) Evacuator valve

Loading...

Loading...