22

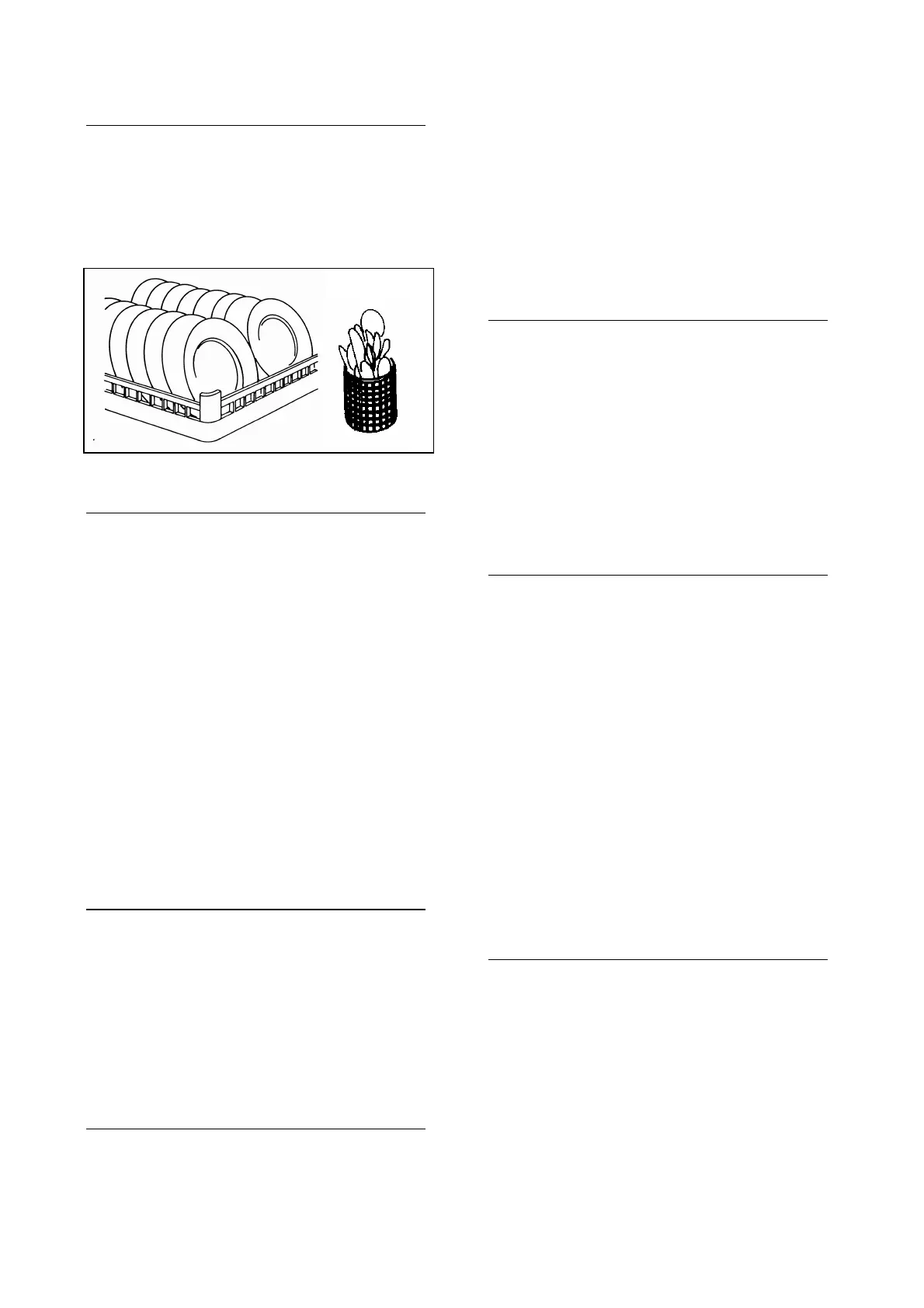

DISHES POSITIONING

It is suitable to place dishes, inside the plastic

basket with the concave side facing upwards.

Place mixed cutlery in a vertical position into the

suitable container minding not to cram them and

with handgrips towards the bottom (see

drawing).

CLEANSING AGENTS

Choice of the suitable cleansing agent is an

essential condition if you want to obtain

extremely good washing results as regards

hygienic results. It is then important to consider

some points. First of all only highly alkaline and

chlorine-active antifoam products, especially

made for industrial dish-washing machines, must

be used and they must be produced by well-

known reliable Firms. Mean concentration of the

cleansing agents in powder must be 1,5÷2,5 g/lt.

Mean concentration of liquid cleansing agents

must be 2÷4 g/lt.

In order to avoid scales and corrosions, put the

cleansing agent above water level on the nearest

area of the sucking pump filter, in this way it will

immediately dilute and will not deposit on the

tank bottom.

RINSING ADDITIVES

To grant a perfect rinsing, a quick drying and to

avoid calcareous sediments on glasses and

cups you must add a surfactant on water

(Brightener).

Your cleansing agent supplier will be able to

suggest the most suitable product. Your

machine is equipped with a rinse aid dispenser.

Mean concentration used is 0,15 g/lt.

DESCALING

When hard water is used you can find, inside the

machine and also on dishes, calcareous

sediments which must be removed both for

hygienic and operating reasons by a descaling

operation.

Operating process and frequency of this

intervention are suggested by your cleansing

agent supplier who has suitable products,

generally containing phosphoric acid.

In order to avoid damage to the machine do not

increase the quantities and once operations end

rinse abundantly.

SANIFICATION

At last each 30 days it would be useful to do this

operation which guarantees the complete

hygienic conditions of the machine. We suggest

to contact your cleansing agent supplier who will

give you quantity and name of the most suitable

product you can use and that, generally, is an

active chloride powder (100÷200 ppm).

In order to avoid damage to the machine do not

increase the quantities and once operations end,

rinse abundantly.

REGENERATING

(for machines with Water-softener)

If the glasswasher is equipped with a Water-

softener it is possible to regenerate the water

(water cleaning).

Every evening, after MAINTENANCE operations,

lift the overflow out of the tank, close the door

and turn the switch "A" on the OFF position.

Push the button "R" until the lamp "H" is lighted.

After twenty (20) minutes the lamp "H" is OFF.

The regeneration of resins has been completed

automatically and the machine is ready to go into

operation again.

Every 6 days add 1 kg of salt in tablet-form in the

bottle placed on the bottom of the tank.

Attention!: the regeneration starts only when

the machine is on the OFF position.

SALT CONTROL

Unscrew the plug of the salt container at the

bottom of the tank and put 1 kg coarse salt tablets

in it.

Clean the gasket and screw the plug.

The lack of sault in the container causes damages

for the machine because of limestone, besides a

defective washing of glasses and dishes.

Loading...

Loading...