BALTIC R410A-IOM-0708-E Page 61

2

nd

method when adjusting the pulley :

-Close the pulley fully and count the number of turns

from fully closed position. Using table_2 determine the

motor pulley actual diameter.

-Record the fix fan pulley diameter.(DF)

-Determine the fan speed using the following formulae:

Where: rpm

MOTOR

:from the motor plate or table_3

D

M

: from table2

D

F

: from machine

Once the pulleys are adjusted and the belt checked and

tensioned, start the fan motor and record the Amps and

Voltage between the phases :

Using the measured data and table_3

-Theoretical mechanical power at the fan shaft:

P

meca fan

= P

meca Motor

x

Transmission

P

meca fan

= P

elec

x

meca motor

x

Transmission

P

meca fan

= V x I x 3 x cos x

meca motor

x

Transmission

This formula can be approximated in this way

P

meca fan

= V x I x 1.73 x 0.85 x 0.76 x 0.9

With the fan “rpm” and the mechanical power at the fan

shaft an operating point and the supplied airflow can be

estimated using the fan curves.

CHECKING AIRFLOW AND ESP

Using the fan curves on page 25, 26, 27, the airflow, the

total pressure available (P

TOT

) and the corresponding

dynamic pressure (Pd) can now be estimated, for a specific

operating point;

The next step consists in estimating the pressure losses

across the unit.

This can be achieved using the “dirty filter pressure sensor”

and the accessories pressure drop table: table_4

Also the pressure drop due to the duct inlet into the roof-top

unit can be taken as 20 to 30 Pa.

P

INT

= P

filter + coil

+ P

Inlet

+ P

Options

using the results from above, the external static pressure

(ESP) can then be estimated:

ESP = P

TOT

- Pd - P

INT

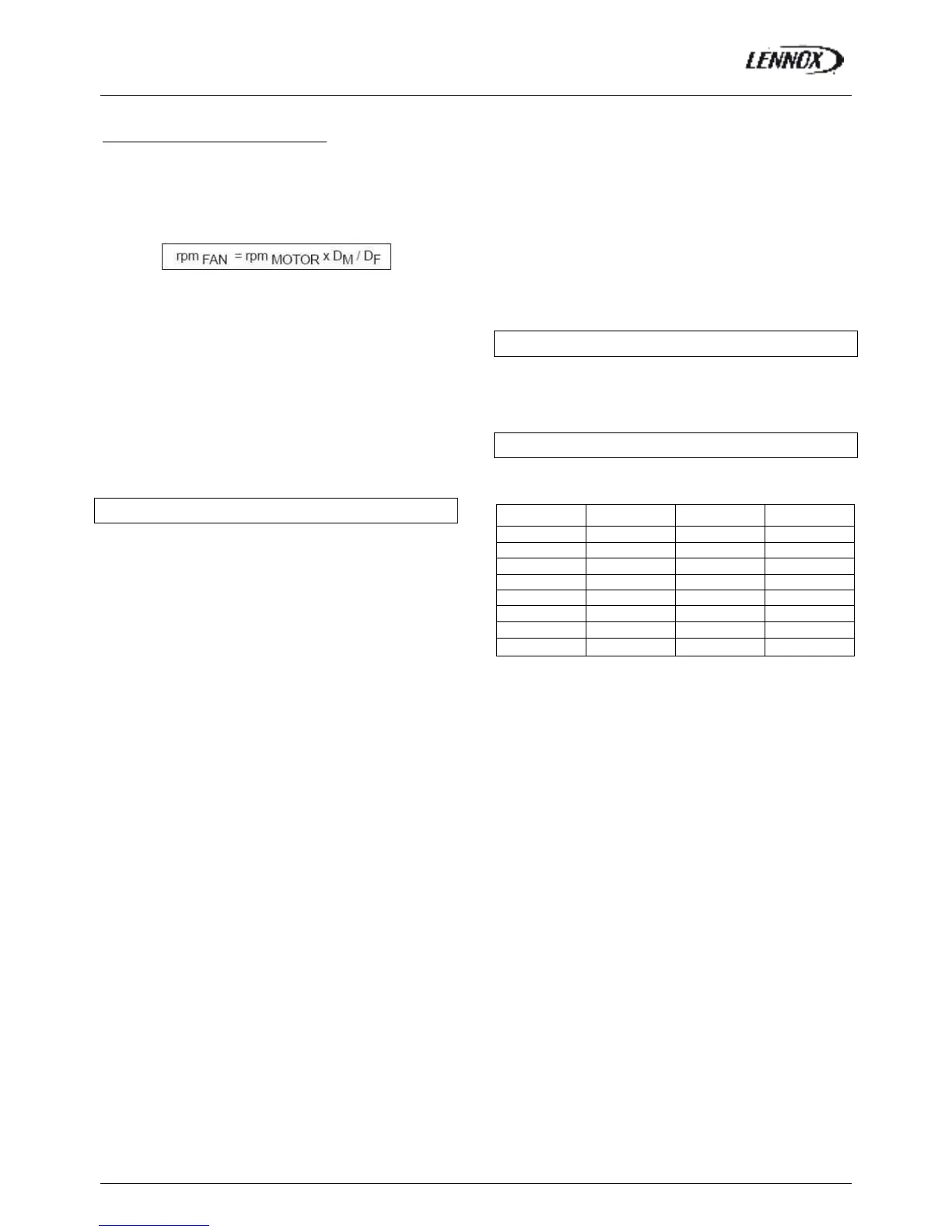

Table_ 3 Motor information

Motor Size Nom. Speed

Cos

meca motor

0.75 kW 1400 rpm 0.77 0.70

1.1kW 1429 rpm 0.84 0.77

1.5kW 1428 rpm 0.82 0.79

2.2kW 1436 rpm 0.81 0.81

3.0kW 1437 rpm 0.81 0.83

4kW 1438 rpm 0.83 0.84

5.5kW 1447 rpm 0.83 0.86

7.5kW 1451 rpm 0.82

0.87

Loading...

Loading...