• 38 • Installation - Operation - Maintenance manual (IOM) • AIR COOLED CHILLERS & SPLIT UNITS - 0105-E

TROUBLESHOOTING - REPAIRS

8.1 LIST OF THE MOST COMMON PROBLEMS - continued

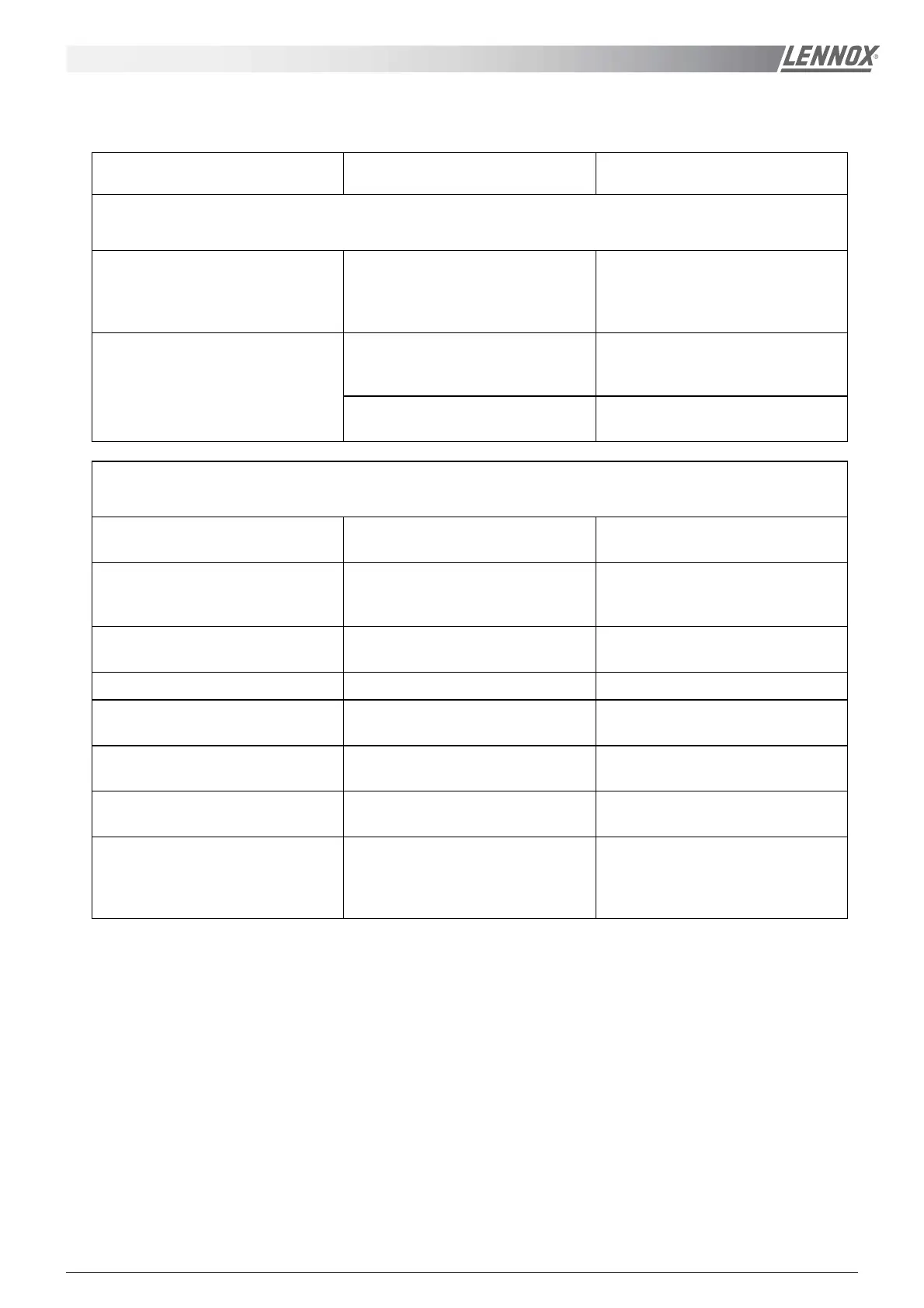

PROBLEMS – SYMPTOMS PROBABLE CAUSE RECOMMENDED ACTION

M) SUCTION PRESSURE IS TOO HIGH

- The compressor runs

continuously

- Too much cooling demand on

the evaporator

- Check the system

a) Expansion valve opened to far a) Adjust superheat and check

that the expansion valve bulb is

correctly fitted in place

- Suction line unusually cold.

Liquid refrigerant returns to

compressor

b) Expansion valve blocked in

open position

b) Repair or replace

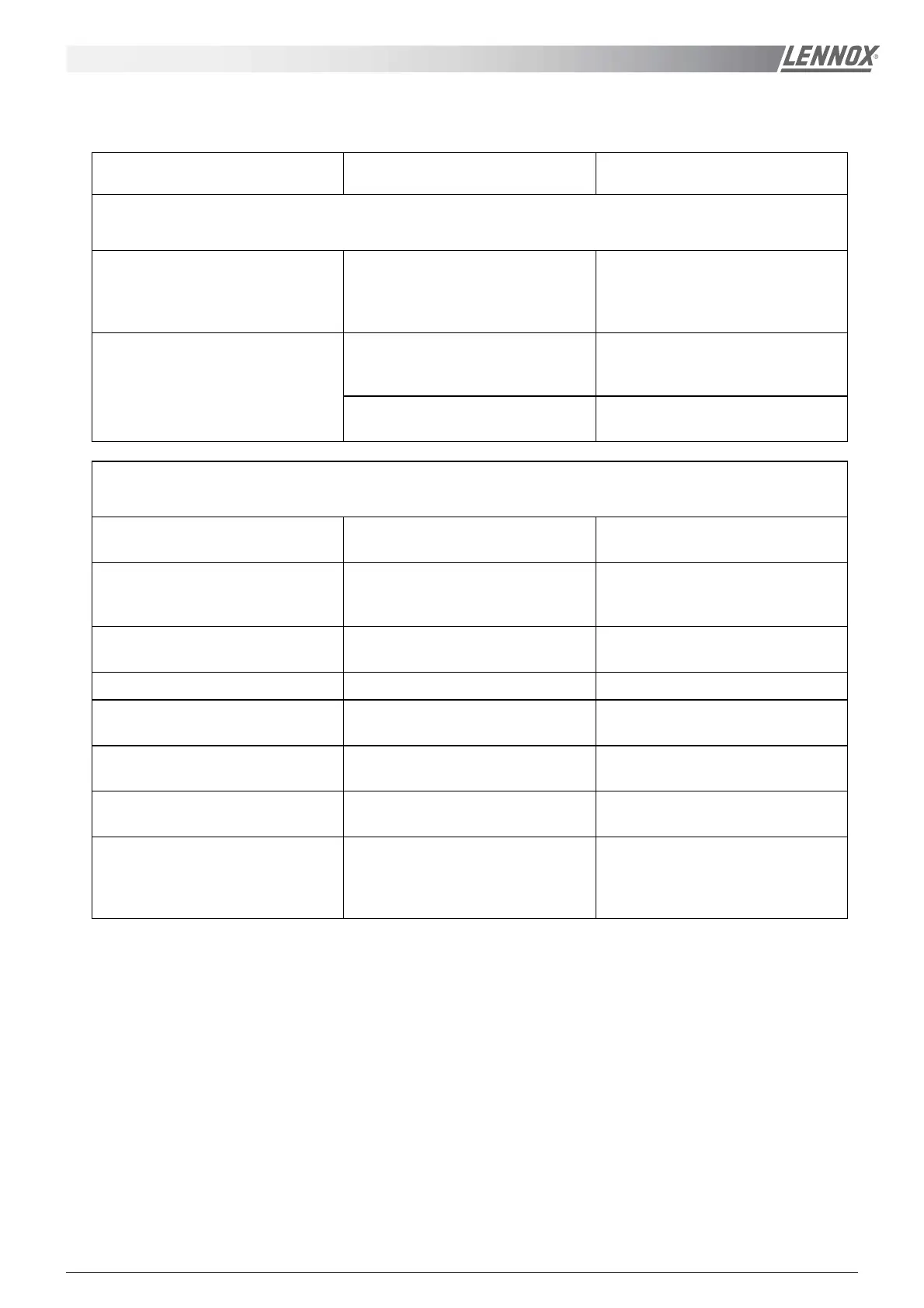

N) SUCTION PRESSURE IS TOO LOW

- Bubbles in sightglass - Low refrigerant charge - Repair the leak and add

refrigerant

- Excessive pressure drop across

the filter-drier or the solenoid

valve

- Filter-drier obstructed - Replace the cartridge

- No refrigerant passing through

the expansion valve

- Expansion valve bulb has lost its

charge.

- Replace the bulb

- Loss of capacity - Expansion valve obstructed - Clean or replace

- Conditioned space too cold - Control thermostat contacts

stuck in closed position

- Repair or replace

- Compressor short-cycling - Capacity modulation setting too

low

- Adjust

- Superheat value too high - Excessive pressure drop in the

evaporator

- Check the external equalizing

line on the expansion valve

- Low pressure drop in the

evaporator

- Low water flow - Check water flow. Check the

condition of the filters, look for

obstructions in the chilled water

circuit piping

Loading...

Loading...