Page 23

ML14XC1 SERIES

Also, ensure that refrigerant pipes are not being

affected by indoor air contamination. Check condition

of insulation on the refrigerant lines. Repair, correct, or

replace as necessary.

7. Inspect the duct system for leaks or other problems.

Repair or replace as necessary.

8. Check for bearing/bushing wear on indoor blower

motor. Replace as necessary.

9. Indoor unit inspections of gas- or oil-fired furnaces will

also include inspection and cleaning of the burners,

and a full inspection of the gas valve, heat exchanger

and flue (exhaust) system.

General System Test with System Operating

1. Your technician should perform a general system test.

He will turn on the air conditioner to check operating

functions such as the startup and shutoff operation.

He will also check for unusual noises or odors, and

measure indoor/outdoor temperatures and system

pressures as needed.

2. The technician will check the refrigerant charge per

the charging sticker information on the outdoor unit.

3. Verify that system total static pressure and airflow

settings are within specific operating parameters.

4. Verify correct temperature drop across indoor coil.

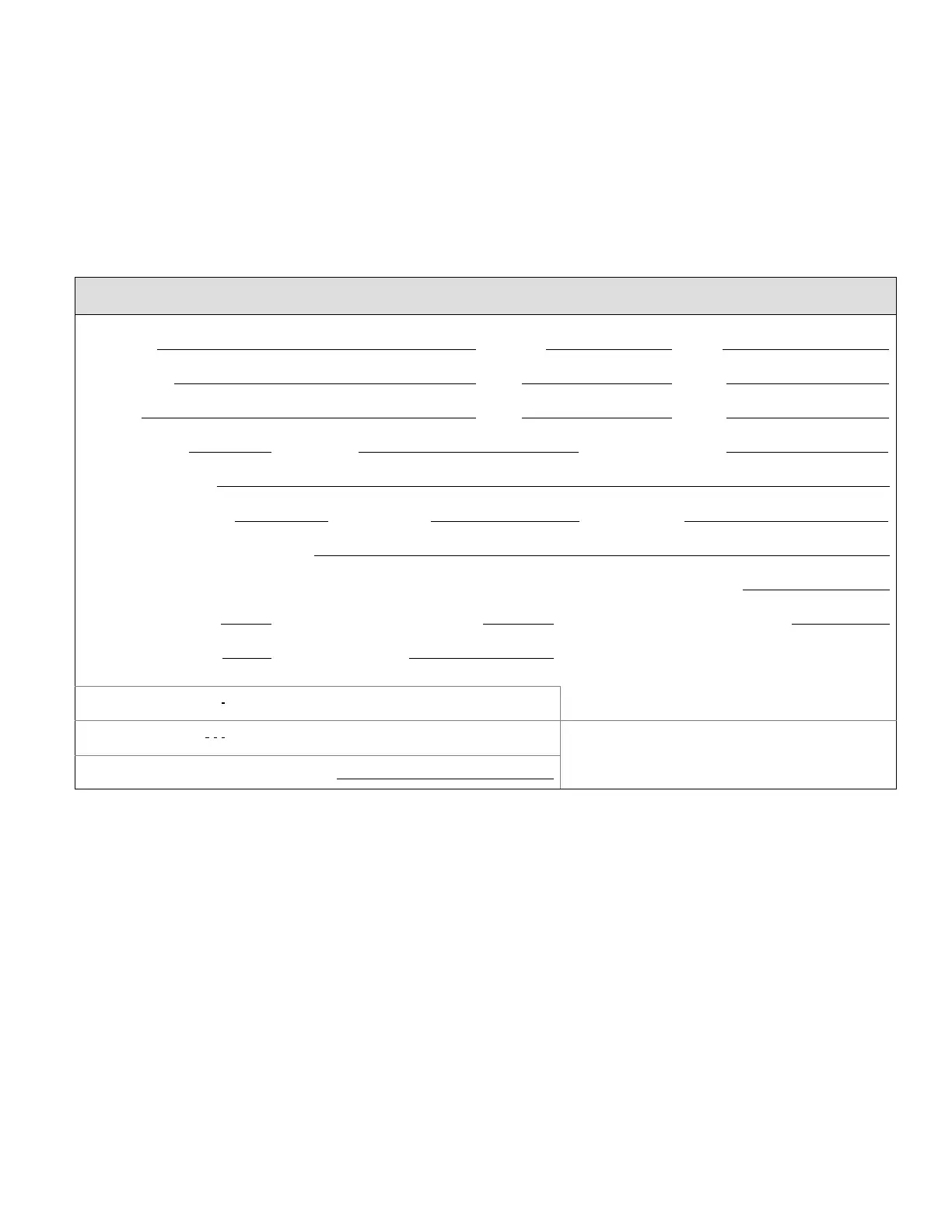

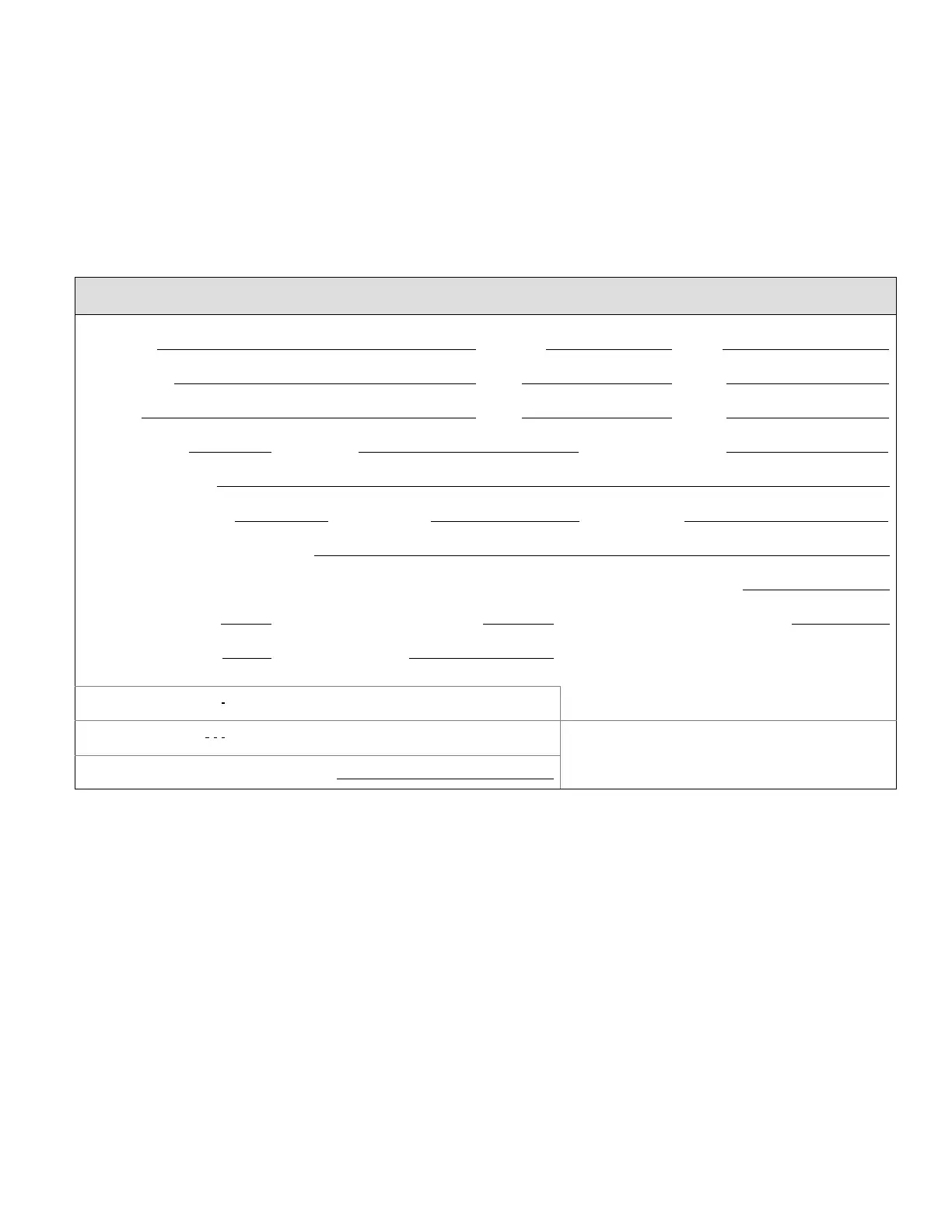

Start-Up and Performance Checklist

Job Name Job no. Date

Job Location City State

Installer City State

Unit Model No. Serial No. Service Technician

Nameplate Voltage

Rated Load Ampacity Compressor Outdoor Fan

Maximum Fuse or Circuit Breaker

Electrical Connections Tight? Indoor Filter clean? Supply Voltage (Unit Off)

Indoor Blower RPM S.P. Drop Over Indoor (Dry) Outdoor Coil Entering Air Temp.

Discharge Pressure Suction Pressure Refrigerant Charge Checked?

Refrigerant Lines: Leak Checked? Properly Insulated? Outdoor Fan Checked?

Service Valves: Fully Opened? Caps Tight? Thermostat

Voltage With Compressor Operating Calibrated? Properly Set? Level?

Loading...

Loading...