Page 34

TABLE 14

APPROACH TEMPERATURE - Fin/Tube - TXV

Unit

Liquid Temp. Minus Ambient Temp.

1st Stage 2nd Stage

092S + +

102S + +

120S + +

150S + +

V- SYSTEMS SERVICE CHECKS

A-Cooling System Service Checks

periodically using the approach method. The approach

method compares actual liquid temperature with the

NOTE - When unit is properly charged, discharge line

pressures should approximate those in TABLE 6 through

TABLE 13.

VI-MAINTENANCE

service technician.

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at disconnect

switch(es). Unit may have multiple power

supplies.

CAUTION

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after

servicing.

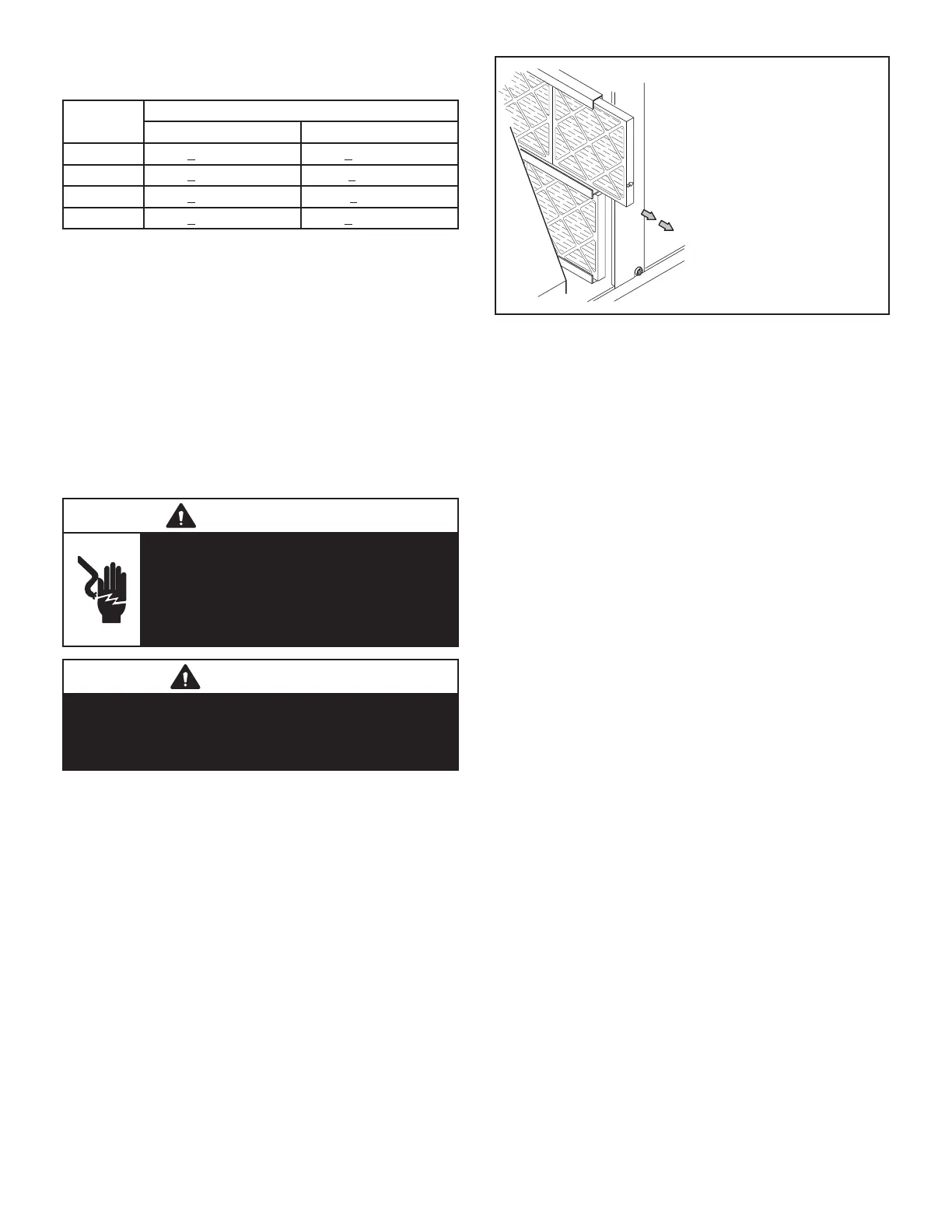

A-Filters

should be checked and replaced when necessary with

NOTE - Filters must be U.L.C. certied or equivalent for

use in Canada.

PULL TO

REMOVE

FILTERS

FIGURE 16

B-Lubrication

lubrication is required.

C-Evaporator Coil

Clean using mild detergent or commercial coil cleaner.

D-Condenser Coil

Clean condenser coil annually with water and inspect

monthly during the cooling season.

prevent damage.

E-Supply Air Blower Wheel

access panel or to clean blower wheel.

F-Electrical

blower motor.

Loading...

Loading...