Page 53

R410A Refrigerant

Units charged with R410A refrigerant operate at much

higher pressures than R22. The expansion valve and liquid

line drier provided with the unit are approved for use with

R410A. Do not replace them with components designed for

use with R22.

R410A refrigerant is stored in a pink cylinder.

IMPORTANT

Mineral oils are not compatible with R410A. If oil

must be added, it must be a polyol ester oil.

Manifold gauge sets used with systems charged with

R410A refrigerant must be capable of handling the higher

system operating pressures. The gauges should be rated

for use with pressures of 0−800 on the high side and a low

side of 30" vacuum to 250 psi with dampened speed to 500

psi. Gauge hoses must be rated for use at up to 800 psi of

pressure with a 4000 psi burst rating.

Turn off power to the unit.

C−Refrigerant Charge and Check

WARNING−Do not exceed nameplate charge under any

condition.

This unit is factory charged and should require no further

adjustment. If the system requires charge, reclaim the

charge, evacuate the system, and add required nameplate

charge.

NOTE − System charging is not recommended below 60_F

(15_C). In temperatures below 60_F (15_C) , the charge

must be weighed into the system.

If weighing facilities are not available, or to check the

charge, use the following procedure:

IMPORTANT − Charge unit in standard cooling mode.

1− Attach gauge manifolds and operate unit in cooling mode

until system stabilizes (approximately five minutes).

Make sure all outdoor air dampers are closed.

2− Check each system separately with all stages operat-

ing.

3− Use a thermometer to accurately measure the outdoor

ambient temperature.

4− Apply the outdoor temperature to tables 6 through 19

to determine normal operating pressures.

5− Compare the normal operating pressures to the pres-

sures obtained from the gauges. Minor variations in

these pressures may be expected due to differences in

installations. Significant differences could mean that

the system is not properly charged or that a problem

exists with some component in the system. Correct

any system problems before proceeding.

6− If discharge pressure is high, remove refrigerant from

the system. If discharge pressure is low, add refriger-

ant to the system.

D Add or remove charge in increments.

D Allow the system to stabilize each time refriger-

ant is added or removed.

7− Use the following approach method along with the nor-

mal operating pressures to confirm readings.

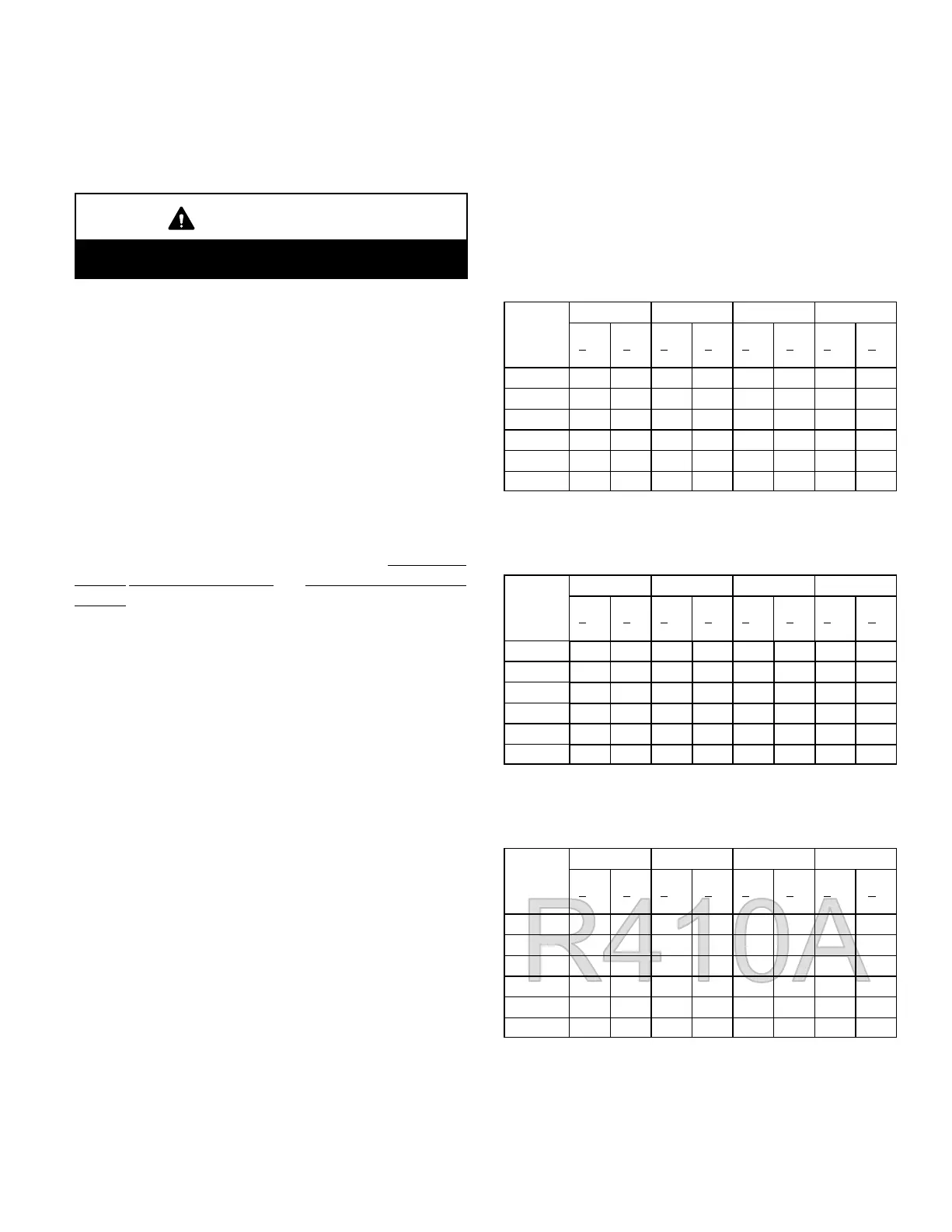

TABLE 6

LGA/LCA Series 248 − R22 − CAV

Outdoor

Coil En-

tering Air

Temp

CIRCUIT 1 CIRCUIT 2 CIRCUIT 3 CIRCUIT 4

DIs

+

10

psig

Suc

+

5

psig

Dis

+

10

psig

Suc

+

5

psig

DIs

+

10

psig

Suc

+

5

psig

DIs

+

10

psig

Suc

+

5

psig

65_F* 158 68 156 72 157 75 156 72

75_F 181 69 183 77 190 82 190 80

85_F 207 70 211 77 218 83 217 80

95_F 235 71 241 78 248 84 248 82

105_F 269 74 273 80 282 86 284 86

115_F 304 76 310 82 320 87 322 85

*Outdoor fans may cycle on and off at this temperature.

TABLE 7

LGA/LCA Series 248 − R22 − VAV

Outdoor

Coil En-

tering Air

Temp

CIRCUIT 1 CIRCUIT 2 CIRCUIT 3 CIRCUIT 4

Dis.

+

10

psig

Suc.

+

5

psig

Dis.

+

10

psig

Suc.

+

5

psig

Dis.

+

10

psig

Suc.

+

5

psig

Dis.

+

10

psig

Suc.

+

5

psig

65_F* 150 71 150 75 158 79 156 81

75_F 181 73 180 77 190 81 190 82

85_F 212 75 210 79 220 82 220 83

95_F 242 78 241 80 252 83 254 84

105_F 274 80 272 82 285 84 288 86

115_F 306 82 302 84 315 85 320 87

*Outdoor fans may cycle on and off at this temperature.

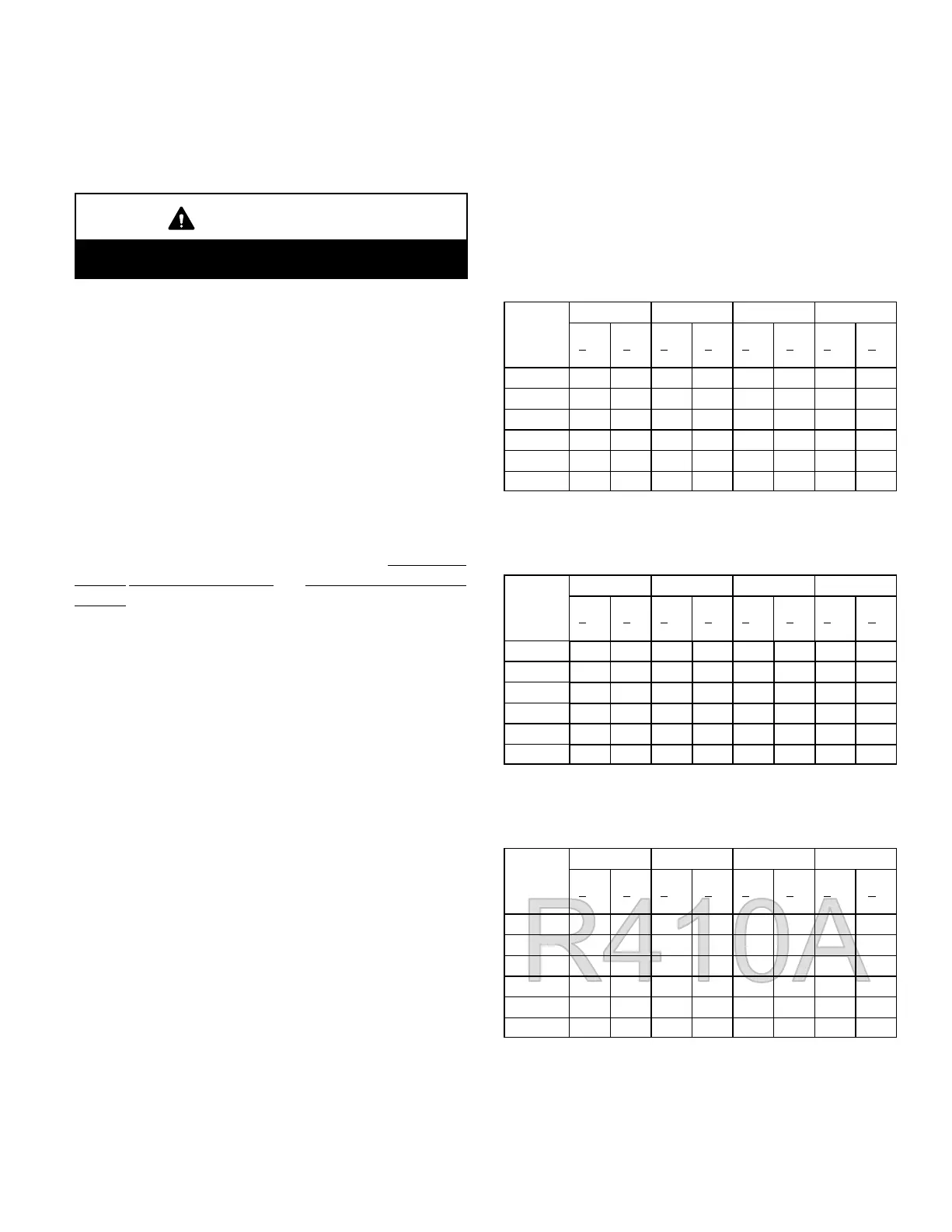

TABLE 8

LGA/LCA Series 248 − R410A − CAV

Outdoor

Coil En-

tering Air

Temp

CIRCUIT 1 CIRCUIT 2 CIRCUIT 3 CIRCUIT 4

Dis.

+

10

psig

Suc.

+

5

psig

Dis.

+

10

psig

Suc.

+

5

psig

Dis.

+

10

psig

Suc.

+

5

psig

Dis.

+

10

psig

Suc.

+

5

psig

65_F* 248 120 250 134 250 139 251 136

75_F 284 122 287 137 288 143 290 139

85_F 324 125 329 139 329 145 332 142

95_F 367 127 374 141 375 147 379 145

105_F 415 131 425 144 425 150 430 147

115_F 468 139 478 146 475 152 485 150

*Outdoor fans may cycle on and off at this temperature.

Loading...

Loading...