Page 42

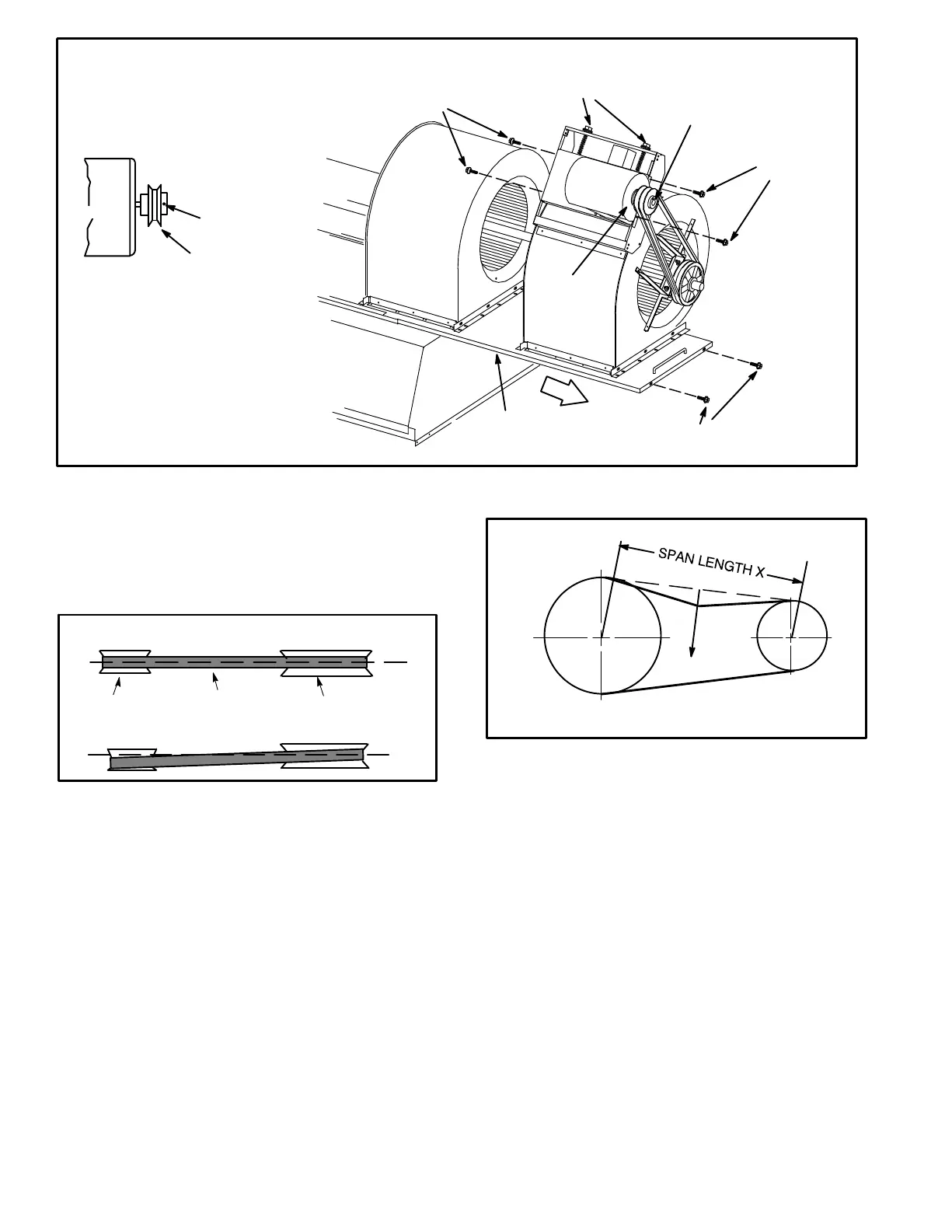

BLOWER ASSEMBLY

TO INCREASE BELT TENSION

1−Loosen four screws securing blower motor to

sliding base.

2−Turn adjusting screw to the left, or counter-

clockwise, to move the motor downward and

tighten the belt.

3−Tighten four screws.

TO INCREASE CFM

LOOSEN ALLEN SCREW &

TURN PULLEY CLOCKWISE

TO DECREASE CFM

TURN PULLEY

COUNTERCLOCKWISE

FIGURE 12

LOOSEN SCREWS

TO ADJUST BELT

TENSION

BLOWER

MOTOR

REMOVE SCREWS TO SLIDE

BLOWER ASSEMBLY OUT OF UNIT

LOOSEN SCREWS TO

ADJUST BELT TENSION

PULLEY

ALLEN

SCREW

BELT TENSION

ADJUSTING SCREWS

BLOWER

ASSEMBLY

SLIDING BASE

PULLEY

MOTOR

ALLEN

SCREW

SIDE VIEW

D−Blower Belt Adjustment

Maximum life and wear can be obtained from belts only if

proper pulley alignment and belt tension are maintained.

Tension new belts after a 24−48 hour period of operation.

This will allow belt to stretch and seat grooves. Make sure

blower and motor pulley are aligned as shown in figure 13.

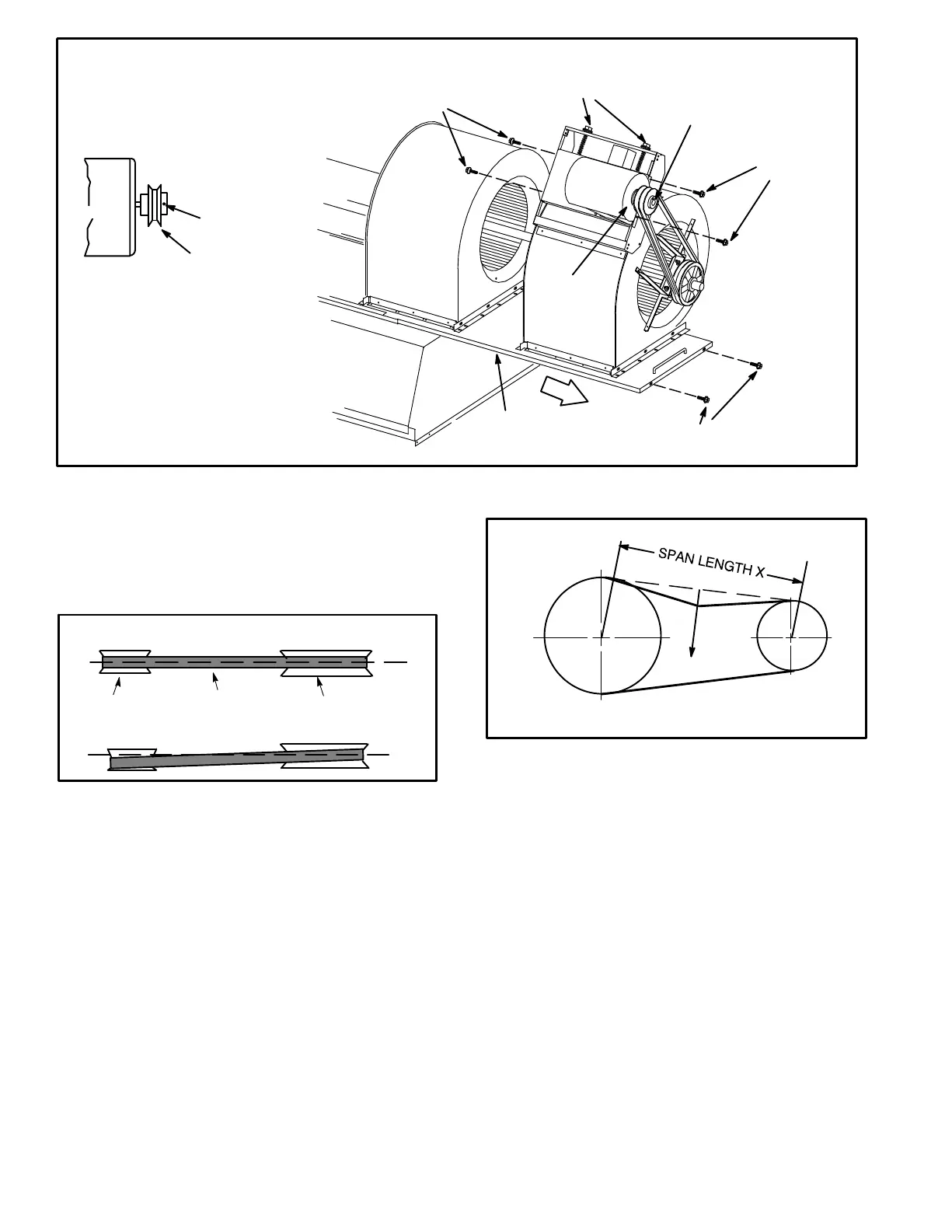

FIGURE 13

PULLEY ALIGNMENT

BELT

BLOWER

PULLEY

MOTOR

PULLEY

NOT ALIGNED

ALIGNED

1− Loosen four screws securing blower motor to sliding

base. See figure 12.

2− To increase belt tension −

Turn belt tension adjusting screw to the left, or counter-

clockwise, to tighten the belt. This increases the dis-

tance between the blower motor and the blower hous-

ing.

To loosen belt tension −

Turn the adjusting screw to the right, or clockwise to

loosen belt tension.

3− Tighten four screws securing blower motor to sliding

base once adjustments have been made.

E−Check Belt Tension

Overtensioning belts shortens belt and bearing life. Check

belt tension as follows:

1− Measure span length X. See figure 14.

MEASURE BELT TENSION

FIGURE 14

DEFLECTION 1/64" PER INCH OF SPAN

OR 1.5mm PER 100mm OF SPAN

FORCE

2− Apply perpendicular force to center of span (X) with

enough pressure to deflect belt 1/64" for every inch of

span length or 1.5mm per 100mm of span length.

Example: Deflection distance of a 40" span would be

40/64" or 5/8".

Example: Deflection distance of a 400mm span would

be 6mm.

3− Measure belt deflection force. For a used belt, the

deflection force should be 5 lbs. (35kPa). A new belt

deflection force should be 7 lbs. (48kPa).

F−Furnished Blower Drives

For field furnished blower drives, see BLOWER DATA

(table of contents) for CFM and PRM. The BLOWER DATA

section also has tables for CAV and VAV drive numbers and

manufacturer’s model numbers.

Loading...

Loading...