Page 58

3− After allowing the unit to stabilize for five minutes, re-

cord the manifold pressure and compare to the values

given for gas supply pressure in table 4.

CAUTION

Disconnect heating demand as soon as an accurate

reading has been obtained.

5−Proper Gas Flow

To check for proper gas flow to burners, determine Btuh in-

put from unit rating plate or the gas heating capacity tables in

the SPECIFICATIONS section of this manual. Divide this in-

put rating by the Btuh per cubic foot of available gas. Result

is the number of cubic feet per hour required. Determine the

flow of gas through gas meter for two minutes and multiply

by 30 to get hourly flow of gas to the burners.

NOTE − To obtain accurate reading, shut off all other gas

appliances connected to meter.

6−Inshot Burner

Burners are factory set for maximum air and cannot be ad-

justed. Always operate unit with access panel in place. A peep

hole is furnished in the heating access panel for flame viewing.

Natural gas should burn basically blue with some clear

streaks. L.P. gas should burn mostly blue with some clear yel-

low streaks.

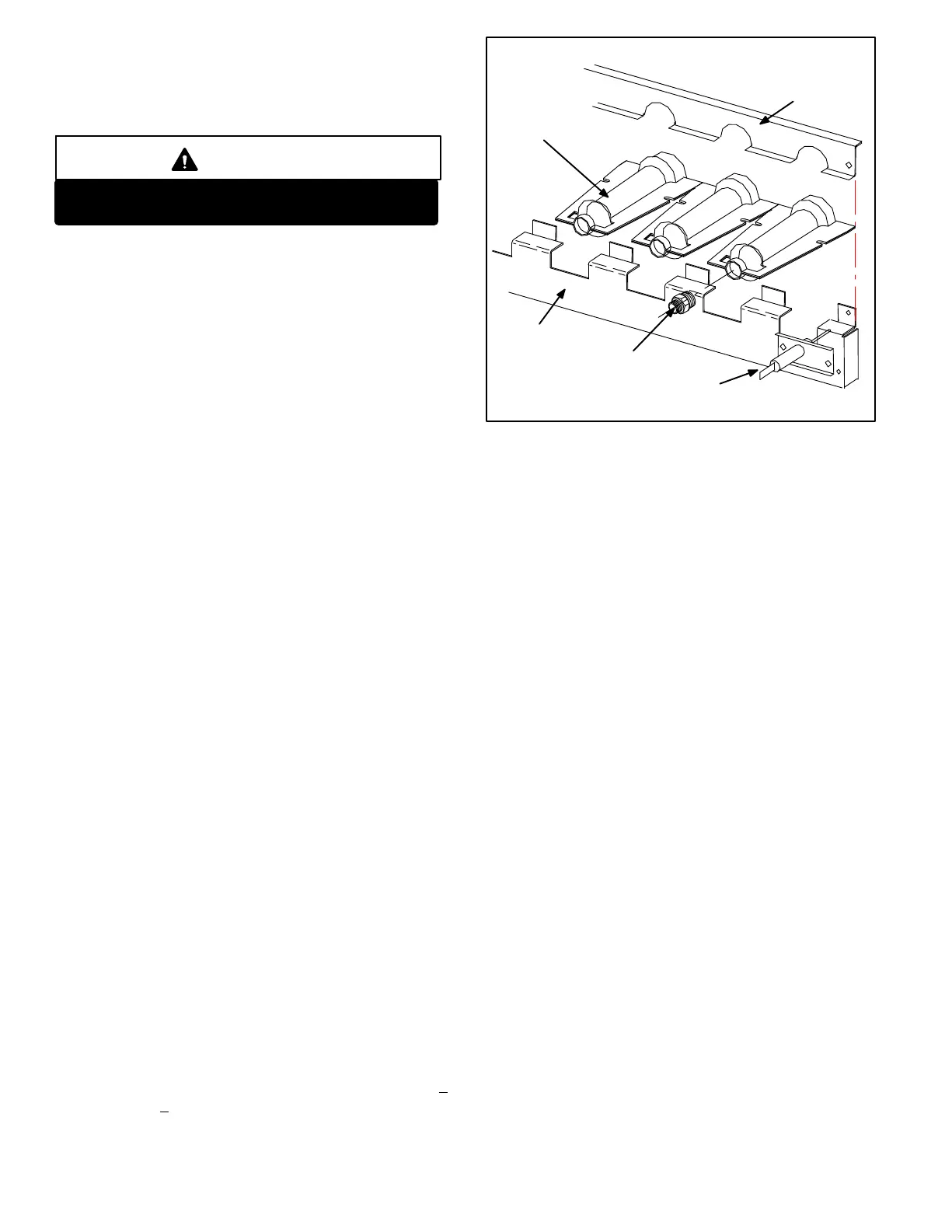

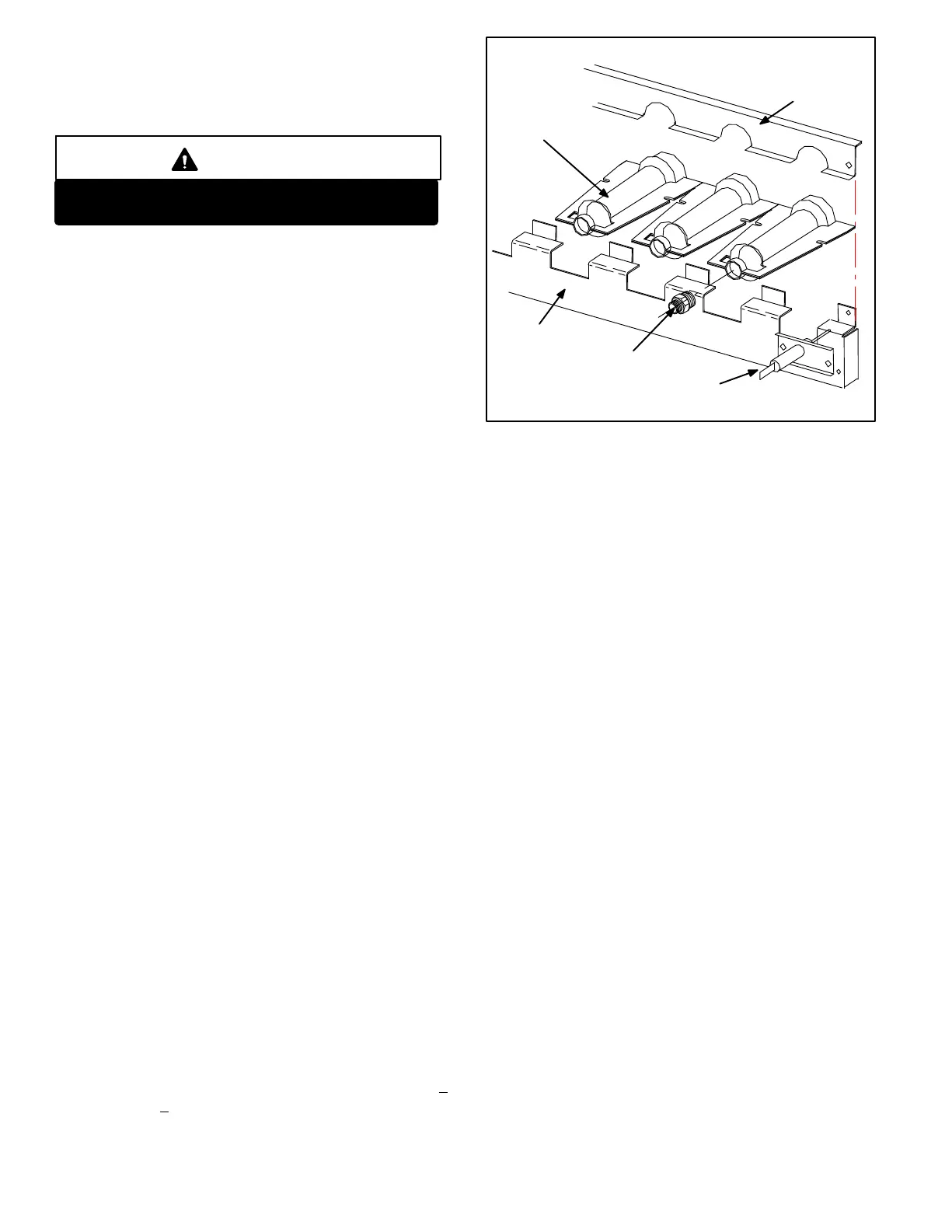

Figure 34 shows how to remove burner assembly.

1− Turn off power to unit and shut off gas supply.

2− Remove screws holding the burner support cap.

3− Slide each burner off its orifice.

4− Clean and reassemble (reverse steps 1−3).

5− Be sure to secure all wires and check plumbing.

6− Turn on power to unit. Follow lighting instructions at-

tached to unit and operate unit in heating mode.

Check burner flames. They should be blue with yellow

streaks.

7−Spark Electrode Gap

The spark electrode assembly can be removed for inspection

by removing two screws securing the electrode assembly

and sliding it out of unit.

For proper unit operation, electrodes must be positioned and

gapped correctly.

Spark gap may be checked with appropriately sized twist drills

or feeler gauges. Disconnect power to the unit and remove

electrode assembly. The gap should be between 0.125" +

0.015" (3.2 mm + .4 mm). See figure 26.

FIGURE 34

BURNER REMOVAL / SENSOR ORIENTATION

BURNERS

ORIFICE

BURNER

SUPPORT

BURNER

SUPPORT

CAP

SENSOR

8−Heat Exchanger

To Access or Remove Heat Exchanger From Unit:

1− Turn off gas and electric power.

2− Remove access panel(s) and unit center mullion.

3− Remove gas valve, manifold assembly and

burners.

4− Remove combustion air blower and flue box. Pay

careful attention to the order in which gaskets and ori-

fice are removed.

5− Support heat exchanger (to prevent it from falling

when final screws are removed.)

6− Remove screws supporting heat exchanger and slide

out.

7− To install heat exchanger, reverse procedure. Be sure

to secure all wires and check plumbing and burner

plate for airtight seal. Screws must be torqued to 35

in.-lbs. (155.7 N) to ensure proper operation.

9−Flame Sensing

Flame current is an electrical current which passes from the

ignition control through the sensor electrode during unit op-

eration. The current passes from the sensor through the

flame to the ground electrode (located on the flame elec-

trode) to complete a safety circuit. See table 21 for flame

signal range. The electrodes should be located so the tips

are at least 1/2" (12.7 mm) inside the flame envelope. Do not

bend electrodes. To measure flame current, follow the pro-

cedure below:

NOTE−Electrodes are not field adjustable. Any alter-

ations to the electrode may create a hazardous con-

dition that can cause property or personal injury.

1− Disconnect power to unit.

Loading...

Loading...