Page 49

Repair Parts List

The following repair parts are available through Lennox

dealers. When ordering parts, include the complete fur-

nace model number listed on the CSA nameplate -- Ex-

ample: ML196UH045XE36B-01. All service must be

performed by a licensed professional installer (or

equivalent), service agency, or gas supplier.

Cabinet Parts

Outer access panel

Blower access panel

Top Cap

Control Panel Parts

Transformer

Integrated control board

Door interlock switch

Blower Parts

Blower wheel

Motor

Motor mounting frame

Blower housing cuto plate

Heating Parts

Flame Sensor

Heat exchanger assembly

Gas manifold

Combustion air inducer

Gas valve

Main burner cluster

Main burner orices

Pressure switch

Ignitor

Primary limit control

Flame rollout switches

THE PROVINCE OF ONTARIO, HORIZONTAL SIDEWALL VENT APPLICATIONS ONLY

For exterior horizontal venting applications, the 2” X 1.5” reducer for 2” venting at the point where the exhaust pipe exits

the structure is not required in direct or nondirect vent applications in the Province of Ontario. In these applications, the

vent should be oriented such that the exhaust plume is unobjectionable. If the installation requires more separation be-

tween the ue gases and the building structure, a reducer may be installed on the exhaust pipe to increase the ue gas

velocity.

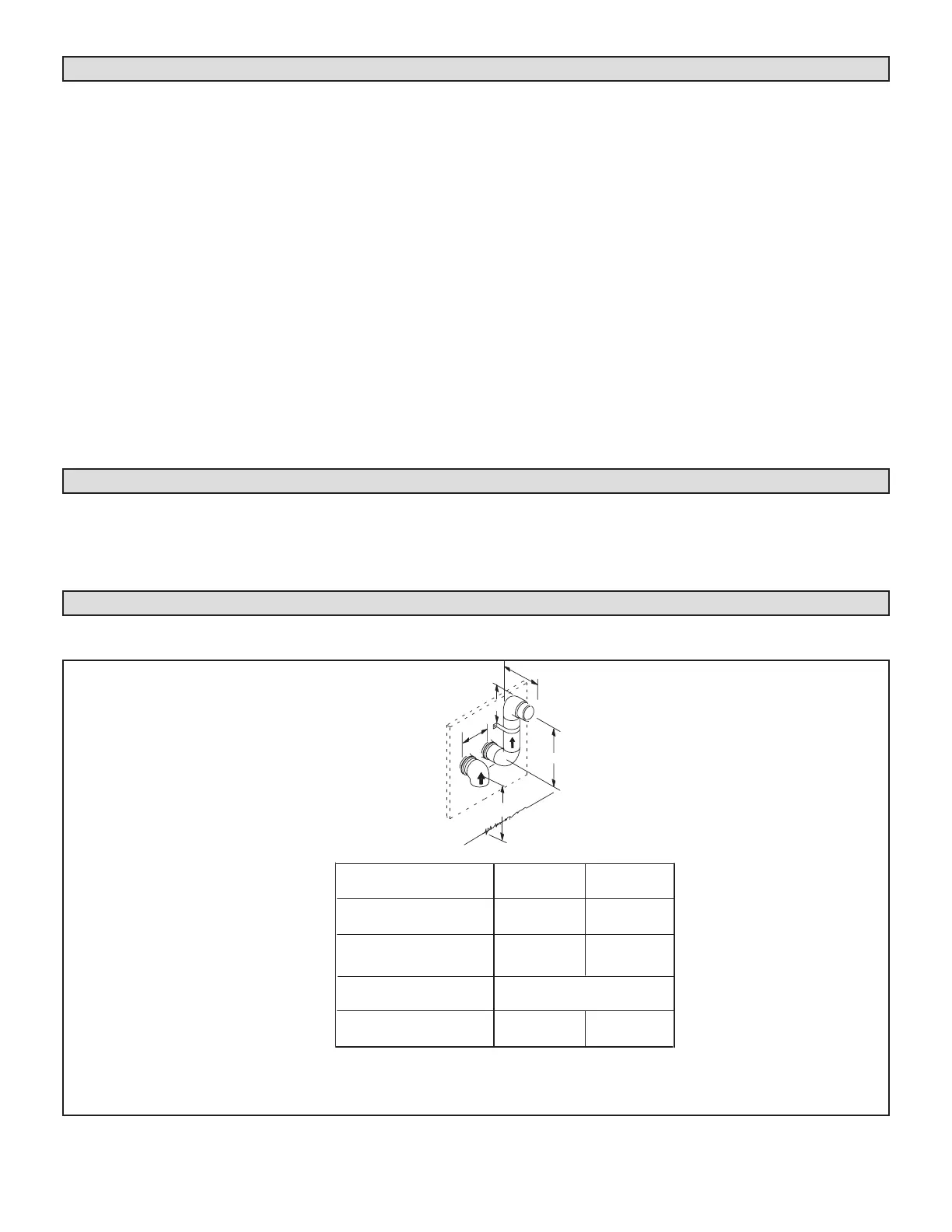

ADDENDUM FOR ALL THE PROVINCES OF CANADA

See below for venting in all the provinces of Canada. Lennox approves the following termination for use in all the provinces

of Canada.

C

12”

D

B

A

2” (51MM)

Vent Pipe

3” (76MM)

Vent Pipe

12” (305 mm) Min. 12” (305 mm) Min.

6” (152 mm) Min.

24” (610 mm) Max.

6” (152 mm) Max.

6” (152 mm) Min.

24” (610 mm) Max.

6” (152 mm) Max.

A − Clearance above grade or

average snow accumulation

B − Horizontal separation between

intake and exhaust

C − Exhaust pipe length

D − Wall support distance from top

of each pipe (intake/exhaust)

NOTE − Flue gas may be acidic and may adversely affect some building materials. If flue gases impinge

on the building materials, a corrosion−resistant shield should be used to protect the wall surface. The

shield should be constructed using wood, sheet metal or other suitable material. All seams, joints, cracks,

etc. in affected area, should be sealed using an appropriate sealant.

Per: Saskatchewan Code of Practice

Loading...

Loading...