Page 22

8 - After assembly, wipe excess cement from pipe at end

of fitting socket. A properly made joint will show a

bead around its entire perimeter. Any gaps may indi

cate an improper assembly due to insufficient sol

vent.

9 - Handle joints carefully until completely set.

Venting Practices

FIGURE 20

* See table 9 for allowable pipe.

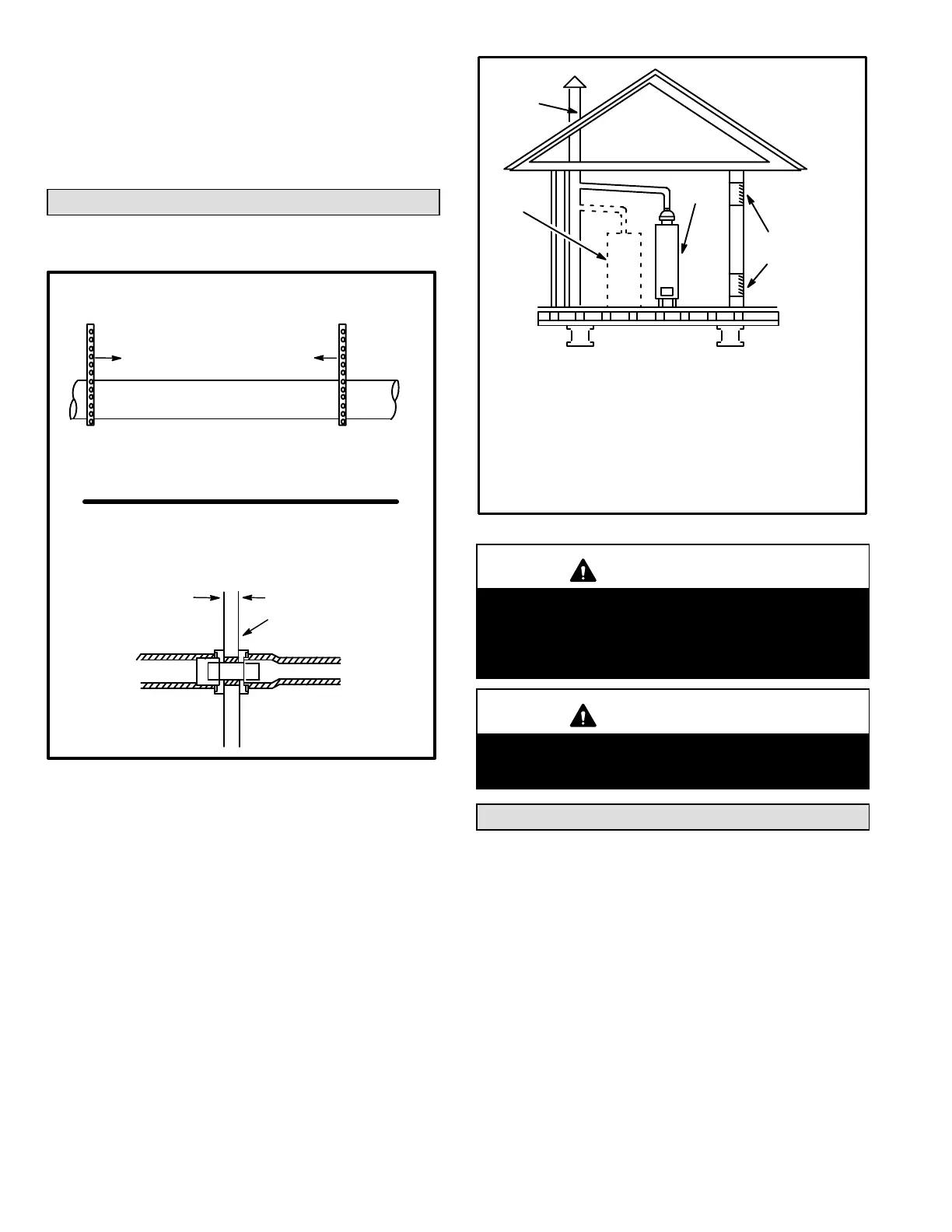

Piping Suspension Guidelines

NOTE - Isolate piping at the point where it exits the outside wall or

roof in order to prevent transmission of vibration to the structure.

SCHEDULE 40

PVC - 5'

all other pipe* - 3'

Wall

inside outside

24” maximum

3/4” minimum

Wall Thickness Guidelines

6. In areas where piping penetrates joists or interior

walls, hole must be large enough to allow clearance on

all sides of pipe through center of hole using a hanger.

7. When furnace is installed in a residence where unit is

shut down for an extended period of time, such as a va

cation home, make provisions for draining condensate

collection trap and lines.

Exhaust Piping (Figures 24 and 25)

Route piping to outside of structure. Continue with installa

tion following instructions given in piping termination sec

tion.

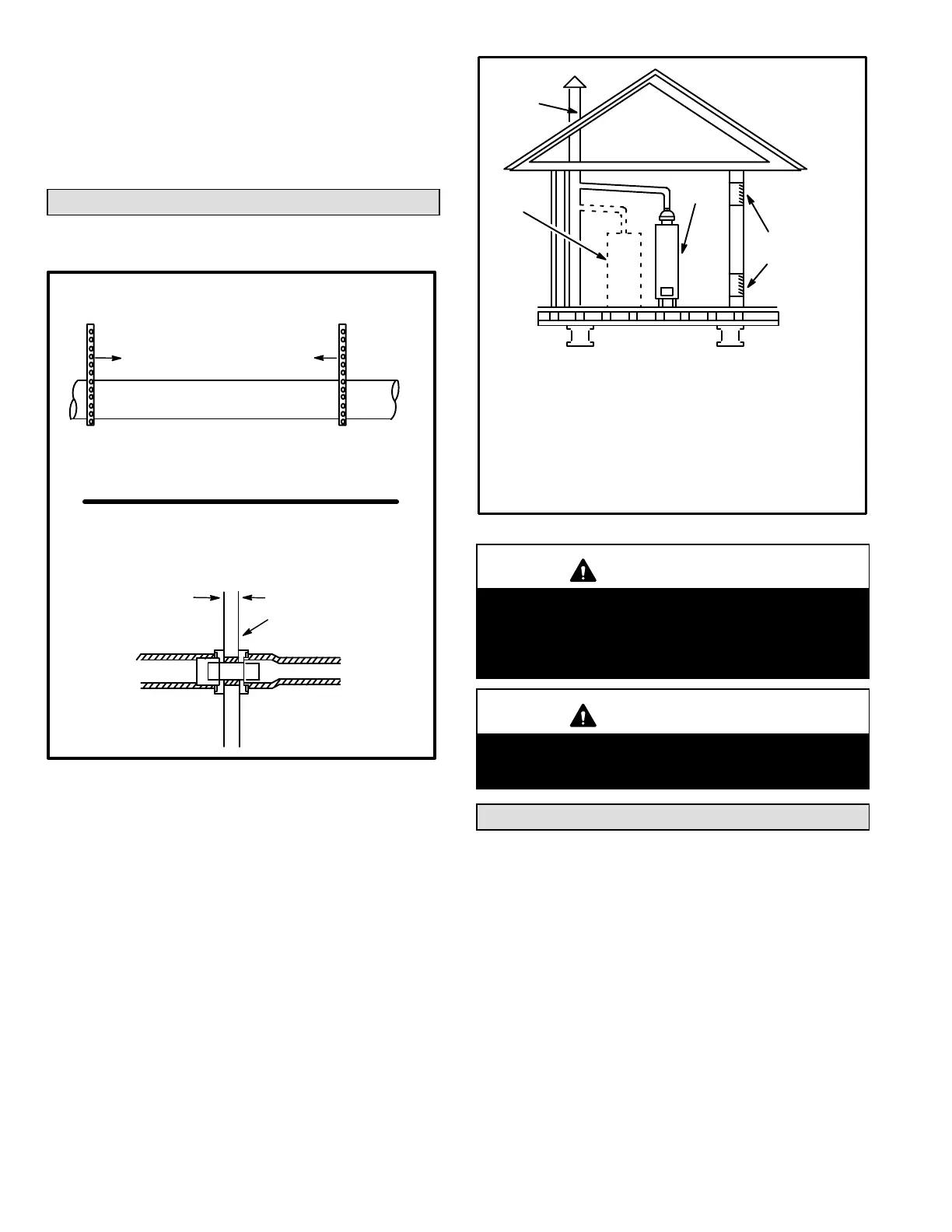

CHIMNEY

OR GAS

VENT

(Check sizing

for water

heater only)

FURNACE

(Replaced

by ML193)

WATER

HEATER

OPENINGS

(To Adjacent

Room)

If an ML193UHE furnace replaces a furnace which

was commonly vented with another gas appliance,

the size of the existing vent pipe for that gas ap

pliance must be checked. Without the heat of the

original furnace flue products, the existing vent pipe

is probably oversized for the single water heater or

other appliance. The vent should be checked for

proper draw with the remaining appliance.

FIGURE 21

REPLACING FURNACE THAT

WAS PART OF A COMMON

VENT SYSTEM

CAUTION

Do not discharge exhaust into an existing stack or

stack that also serves another gas appliance. If verti

cal discharge through an existing unused stack is re

quired, insert PVC pipe inside the stack until the end

is even with the top or outlet end of the metal stack.

CAUTION

The exhaust vent pipe operates under positive pres

sure and must be completely sealed to prevent leak

age of combustion products into the living space.

Vent Piping Guidelines

NOTE - Lennox has approved the use of DuraVent

®

and Cen

trotherm manufactured vent pipe and terminations as an option

to PVC. When using the PolyPro

®

by DuraVent or InnoFlue

®

by

Centrotherm venting system the vent pipe requirements stated

in the unit installation instruction – minimum & maximum vent

lengths, termination clearances, etc. – apply and must be fol

lowed. Follow the instructions provided with PoyPro by Du

raVent and InnoFlue by Centrotherm venting system for as

sembly or if requirements are more restrictive. The PolyPro by

Duravent and InnoFlue by Centrotherm venting system must

also follow the uninsulated and unconditioned space criteria

listed in table 14.

Loading...

Loading...