16

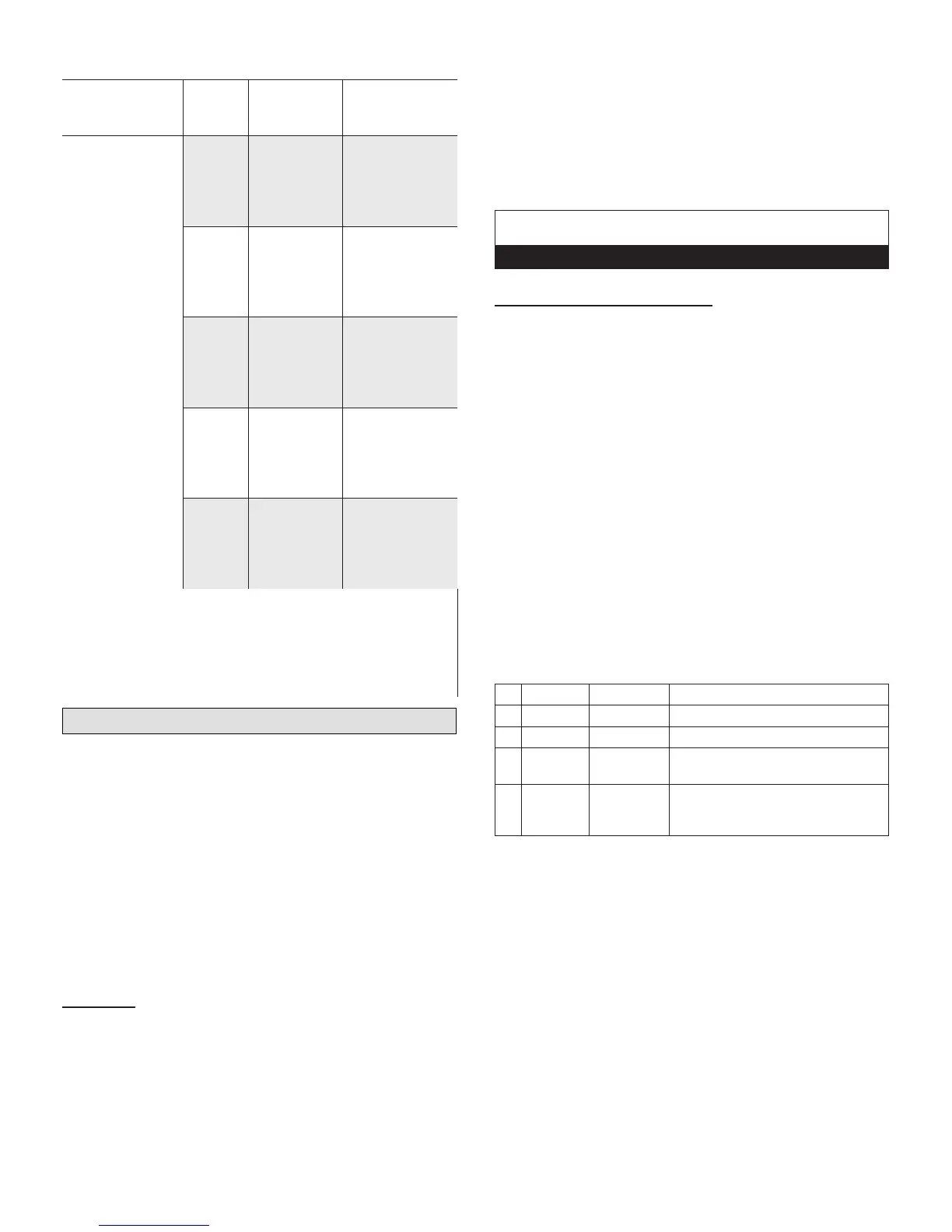

Table 4. Match-Ups

Outdoor

Model

No. of

Zones

Indoor Unit

Capacity

(Unit No.)

Line Set

Required

(Liquid x Gas)

MLA036S4M

Indoor Unit A

1/4” liq + 1/2” gas

Indoor Unit B

1/4” liq + 1/2” gas

Indoor Unit C

1/4” liq + 3/8” gas

Indoor Unit D

1/4” liq + 3/8” gas

4

009 (B)

1

1/4 in. x 3/8 in.

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

018 (A) 1/4 in. x 1/2 in.

4

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

4

009 (C) 1/4 in. x 3/8 in.

009 (D) 1/4 in. x 3/8 in.

012 (B) 1/4 in. x 1/2 in.

018 (A) 1/4 in. x 1/2 in.

4

009 (D) 1/4 in. x 3/8 in.

012 (A) 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

012 (C)

1

1/4 in. x 1/2 in.

4

012 (A) 1/4 in. x 1/2 in.

012 (B) 1/4 in. x 1/2 in.

012 (C)

1

1/4 in. x 1/2 in.

012 (D)

1

1/4 in. x 1/2 in.

1

3/8 x 1/2 in. gas pipe adaptor is required for line set connection to outdoor unit

(furnished with outdoor unit).

2

1/4 x 3/8 in. liquid pipe adaptor is required for line set connection to the 048

outdoor unit (furnished with outdoor unit).

3

1/2 x 5/8 in. gas pipe adaptor is required for line set connection to the 048

outdoor unit (furnished with outdoor unit).

4

Not a valid combination when using the MPA036S4M.

Leak Test and Evacuation

Air and moisture remaining in the refrigerant system will

have undesirable effects as indicated below:

• Pressure in the system rises

• Operating current rises

• Cooling or heating efciency drops

• Moisture in the refrigerant circuit may freeze

• Water may lead to corrosion of parts in the refrigera-

tion system

The line set between the indoor and outdoor units

must be leak tested and evacuated to remove any non-

condensables and moisture from the system.

Leak Test

Use the following procedure to test for system leaks:

1. Connect the manifold gauge set and dry nitrogen gas

cylinder to the liquid and gas service ports.

2. Open valve on nitrogen cylinder.

3. Pressurize the system per the pressure test

specications in “Table 5. Pressure Test Specications”.

4. Check that the system pressure remains stable. If

there is any movement check system for leaks.

5. After the system is found to be free of leaks:

• Close valve on nitrogen cylinder.

• Relieve the nitrogen pressure by: loosening the

charge hose connector at the nitrogen cylinder.

• When the system pressure is reduced to normal,

disconnect the hose from the cylinder.

IMPORTANT

Use only oxygen-free nitrogen (OFN).

Triple Evacuation Procedure

A Micron or Torr gauge must be used for this procedure.

1. Discharge the oxygen-free nitrogen and evacuate the

system to a reading of 8000 Microns (8 Torr) using all

service valves.

2. Break the vacuum by allowing nitrogen into the port

connections (liquid and gas line pipes) until a positive

pressure is achieved.

3. Evacuate the system to a reading of 5000 Microns (5

Torr).

4. Break the vacuum by allowing nitrogen into the port

connections (liquid and gas line pipes) until a positive

pressure is achieved

5. Evacuate the system to a minimum reading of 500

Microns (0.5 Torr).

6. For a moisture-free system, ensure the vacuum is held

without movement for a minimum of 4 hours.

7. If vacuum fails to hold, carry out steps 2 through 6 until

vacuum holds.

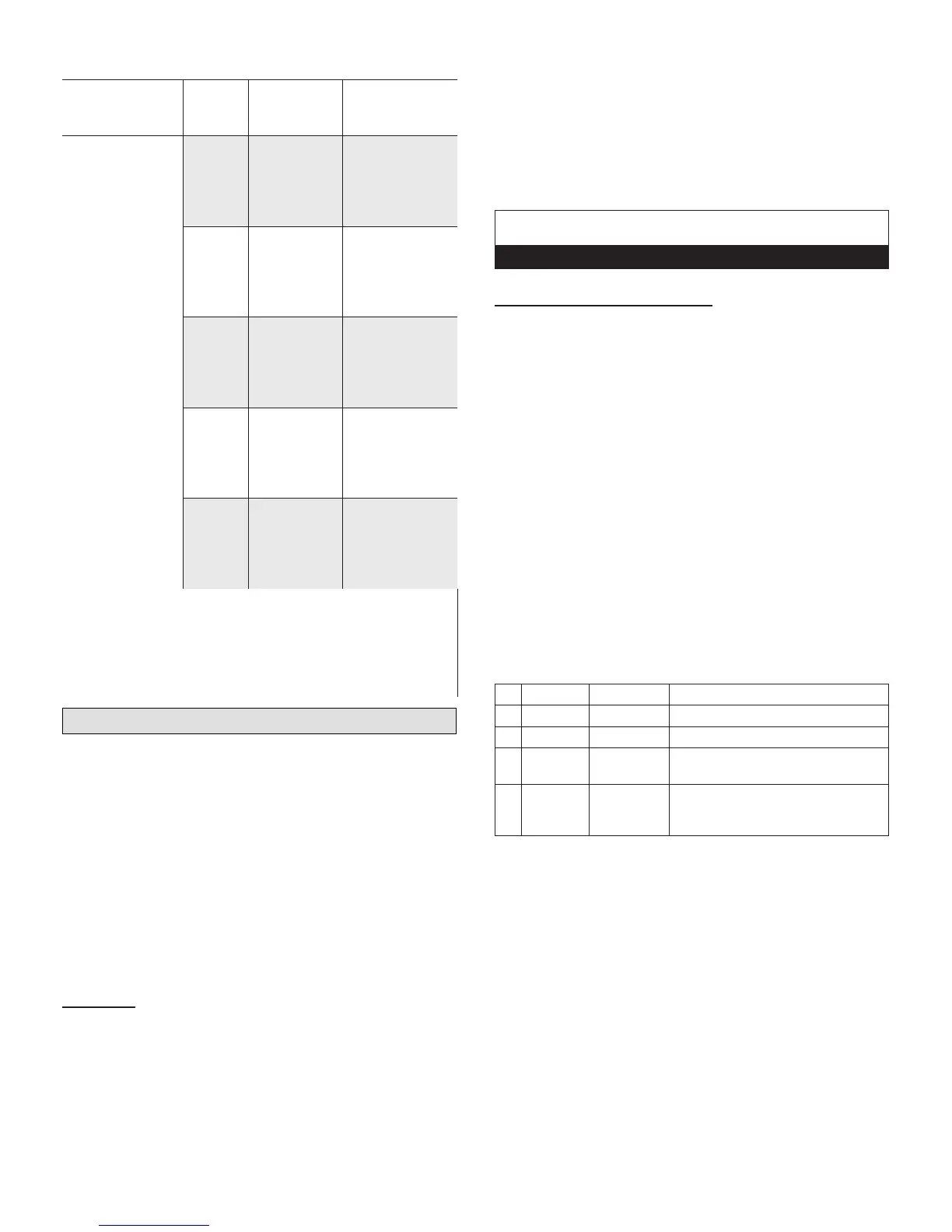

Table 5. Pressure Test Specications

1 3 bar 44 psig Minimum of 10 minutes

2 15 bar 220 psig Minimum of 10 minutes

3 32 bar 470 psig Minimum of 10 minutes

4 45 bar 650 psig 1 hour. Stress test to prove the

integrity of the complete installation.

5 32 bar 470 psig 24 hours. Lower system pressure

test, after conrmation No. 4 was

successfully completed.

Loading...

Loading...