Page 28

XP21

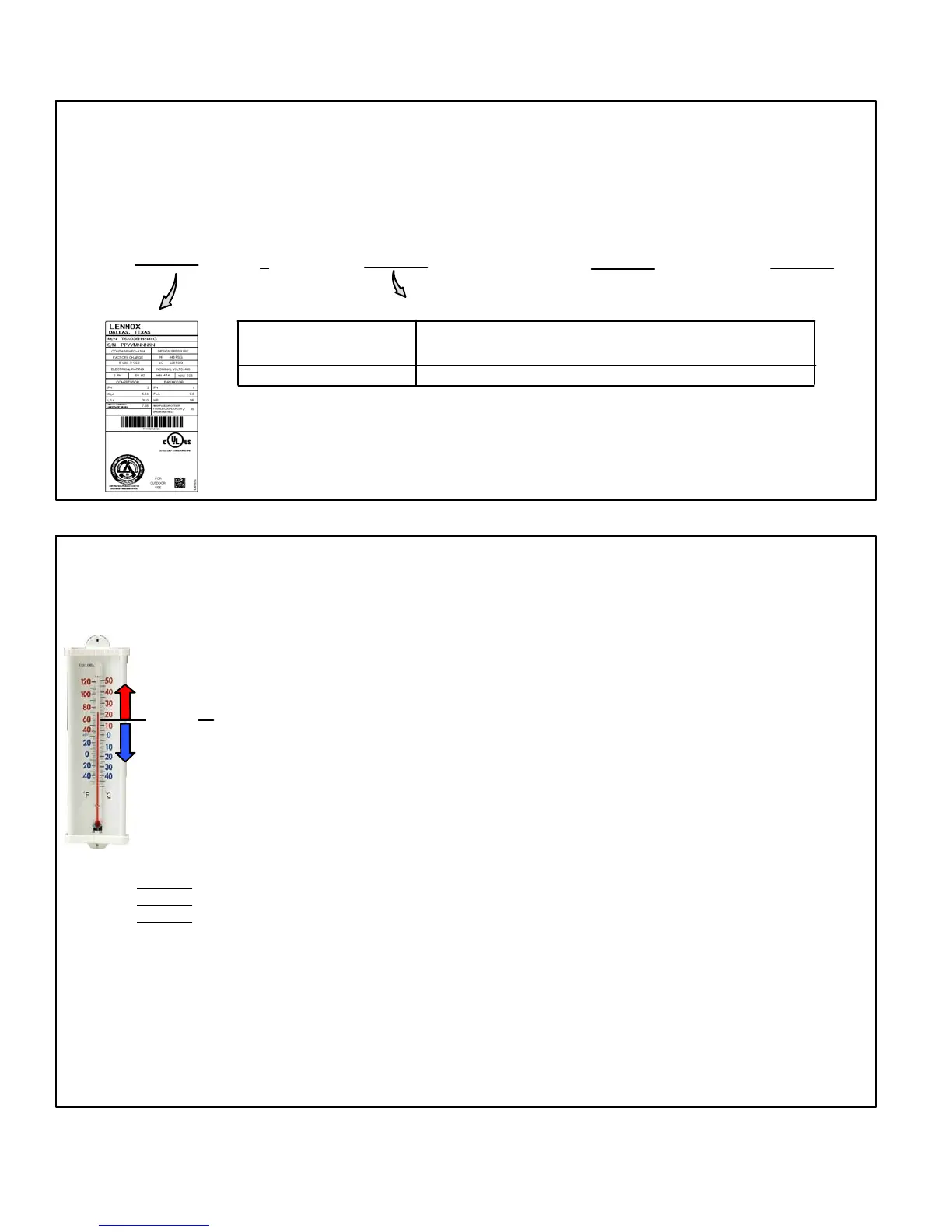

Use WEIGH IN method for adding initial refrigerant charge, and then use SUBCOOLING method for for veri-

fying refrigerant charge.

WEIGH IN

LIQUID LINE SET DIAMETER

OUNCES PER 5 FEET (G PER 1.5 M) ADJUST FROM 15 FEET (4.6 M)

LINE SET*

3/8" (9.5 MM)

3 OUNCE PER 5’ (85 G PER 1.5 M)

*IF LINE LENGTH IS GREATER THAN 15 FT. (4.6 M), ADD THIS AMOUNT. IF LINE LENGTH IS LESS THAN 15 FT. (4.6

M), SUBTRACT THIS AMOUNT.

Refrigerant Charge per Line Set Length

NOTE THE ABOVE NAMEPLATE IS FOR ILLUSTRATION PURPOSES ONLY. GO TO ACTUAL NAMEPLATE ON OUTDOOR

UNIT FOR CHARGE INFORMATION.

CHARGING METHOD

NOTE INSULATE LIQUID LINE WHEN IT IS ROUTED THROUGH AREAS WHERE THE SURROUNDING AMBIENT

TEMPERATURE COULD BECOME HIGHER THAN THE TEMPERATURE OF THE LIQUID LINE OR WHEN PRESSURE

DROP IS EQUAL TO OR GREATER THAN 20 PSIG.

CALCULATING SYSTEM CHARGE FOR OUTDOOR UNIT VOID OF CHARGE

IF THE SYSTEM IS VOID OF REFRIGERANT, FIRST, LOCATE AND REPAIR ANY LEAKS AND THEN WEIGH IN THE REFRIGERANT CHARGE INTO THE UNIT.

TO CALCULATE THE TOTAL REFRIGERANT CHARGE:

AMOUNT SPECIFIED

ON NAMEPLATE

ADJUST AMOUNT. FOR VARIATION IN

LINE SET LENGTH LISTED ON LINE

SET LENGTH TABLE BELOW.

ADDITIONAL CHARGE SPECIFIED

PER INDOOR UNIT MATCH−UPS

STARTING ON PAGE 29

TOTAL

CHARGE

+

+

=

Figure 17. Using HFC−410A Weigh In Method

1. CHECK THE AIRFLOW AS ILLUSTRATED IN FIGURE 16 TO BE SURE THE INDOOR AIRFLOW IS AS REQUIRED. (MAKE

ANY AIR FLOW ADJUSTMENTS BEFORE CONTINUING WITH THE FOLLOWING PROCEDURE.)

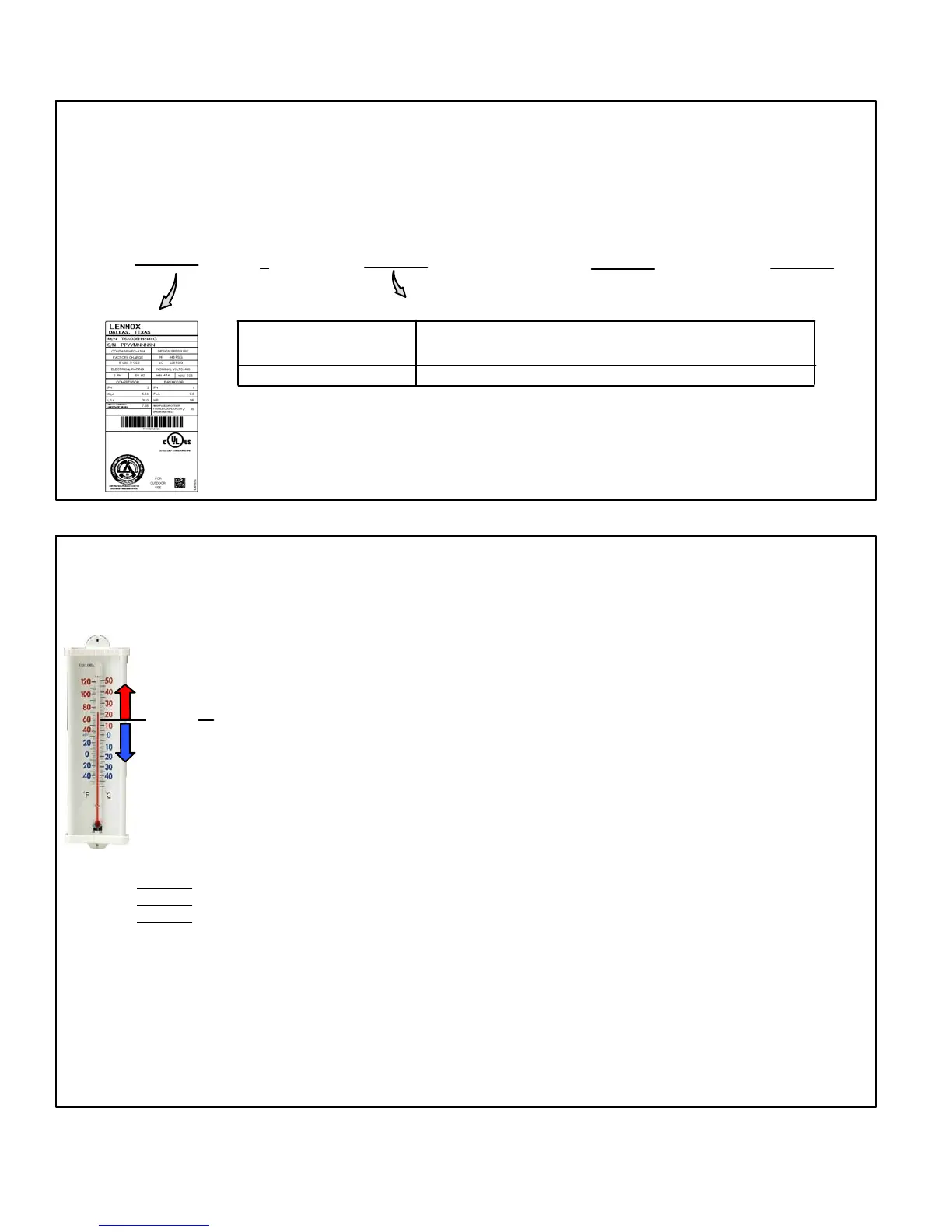

2. MEASURE OUTDOOR AMBIENT TEMPERATURE; DETERMINE WHETHER TO USE COOLING MODE OR HEATING MODE

TO CHECK CHARGE.

3. CONNECT GAUGE SET.

4. CHECK LIQUID AND VAPOR LINE PRESSURES. COMPARE PRESSURES WITH EITHER HEAT OR COOLING MODE

NORMAL OPERATING PRESSURES IN TABLE 8, NORMAL OPERATING PRESSURES, HIGH STAGE.

NOTE

THE REFERENCE TABLE IS A GENERAL GUIDE. EXPECT MINOR PRESSURE VARIATIONS. SIGNIFICANT

DIFFERENCES MAY MEAN IMPROPER CHARGE OR OTHER SYSTEM PROBLEM.

5. SET THERMOSTAT FOR HEAT/COOL DEMAND, DEPENDING ON MODE BEING USED:

USE

COOLING

MODE

USE

HEATING

MODE

60ºF

(15ºC)

SATº

LIQº –

SCº =

SUBCOOLING

6. READ THE LIQUID LINE TEMPERATURE; RECORD IN THE LIQº SPACE.

7. READ THE LIQUID LINE PRESSURE; THEN FIND ITS CORRESPONDING TEMPERATURE IN THE TEMPERATURE/

PRESSURE CHART LISTED IN TABLE 9 AND RECORD IT IN THE SATº SPACE.

8. SUBTRACT LIQº TEMPERATURE FROM SATº TEMPERATURE TO DETERMINE SUBCOOLING; RECORD IT IN SCº

SPACE.

9. COMPARE SCº RESULTS WITH TABLES 3 THROUGH 7, BEING SURE TO NOTE ANY ADDITIONAL CHARGE FOR LINE

SET AND/OR MATCH−UP.

10. IF SUBCOOLING VALUE IS GREATER THAN SHOWN IN TABLES 3 THROUGH 7 FOR THE APPLICABLE UNIT, REMOVE

REFRIGERANT; IF LESS THAN SHOWN, ADD REFRIGERANT.

11. IF REFRIGERANT IS ADDED OR REMOVED, REPEAT STEPS 5 THROUGH 6 TO VERIFY CHARGE.

12. DISCONNECT GAUGE SET AND RE−INSTALL BOTH THE LIQUID AND SUCTION SERVICE VALVE CAPS.

USING COOLING MODE WHEN THE OUTDOOR AMBIENT TEMPERATURE IS 60°F (15°C) AND ABOVE. TARGET

SUBCOOLING VALUES (SECOND STAGE − HIGH CAPACITY) IN TABLE 8 ARE BASED ON 70 TO 80°F (21−27°C) INDOOR

RETURN AIR TEMPERATURE; IF NECESSARY, OPERATE HEATING TO REACH THAT TEMPERATURE RANGE; THEN

SET THERMOSTAT TO COOLING MODE SETPOINT TO 68ºF (20ºC) WHICH SHOULD CALL FOR SECOND−STAGE (HIGH

STAGE) COOLING. WHEN PRESSURES HAVE STABILIZED, CONTINUE WITH STEP 6.

USING HEATING MODE WHEN THE OUTDOOR AMBIENT TEMPERATURE IS BELOW 60°F (15°C). TARGET

SUBCOOLING VALUES (SECOND−STAGE − HIGH CAPACITY) IN TABLE 8 ARE BASED ON 65−75°F (18−24°C) INDOOR

RETURN AIR TEMPERATURE; IF NECESSARY, OPERATE COOLING TO REACH THAT TEMPERATURE RANGE; THEN

SET THERMOSTAT TO HEATING MODE SETPOINT TO 77ºF (25ºC) WHICH SHOULD CALL FOR SECOND−STAGE (HIGH

STAGE) HEATING. WHEN PRESSURES HAVE STABILIZED, CONTINUE WITH STEP 6.

CHARGING METHOD

Figure 18. Using HFC−410A Subcooling Method High Stage (High Capacity)

Loading...

Loading...