Installation - Operation - Maintenance manual (IOM) • AIR COOLED CHILLERS & SPLIT UNITS - 0105-E • 73 •

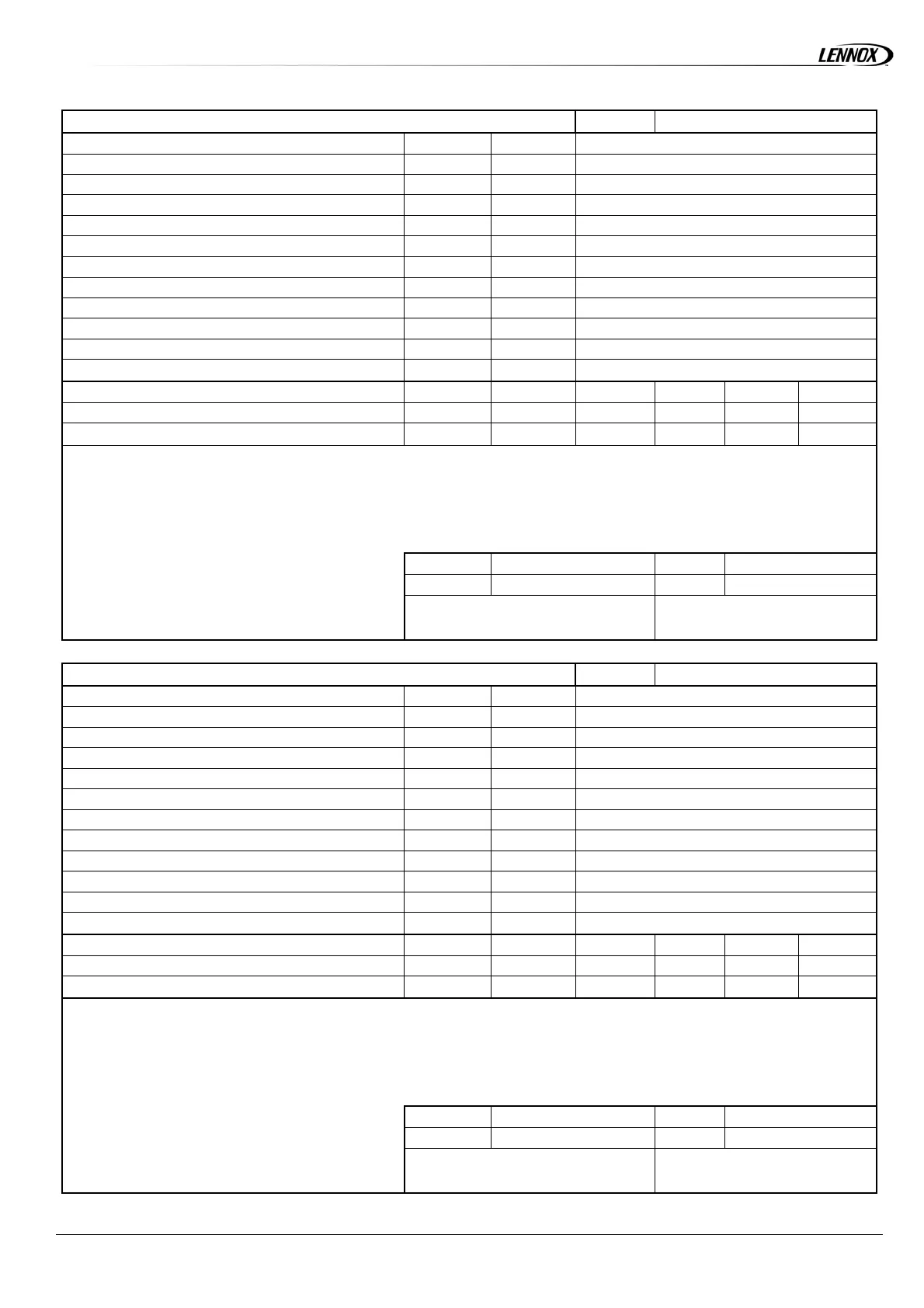

MAINTENANCE LOGBOOK

MAINTENANCE visit n° 1 (500H / 1000H) Date

Y / N Value Comments

Unit general control (corrosion, damages…)

Exchanger cleaning

Leak test done

Oil acidity test carried

Replacement of filter drier cartridge

Water filters cleans

Evaporator pressure drop Kpa

Water condenser pressure drop Kpa

Glycol concentration level %

Unit operating parameters checked and in conformity

Fans currents level checked and in conformity

Compressors data CP1 CP2 CP3 CP4 CP5 CP6

Operating hours

Current at 100% load

Comments et remarks:

TECHNICIAN CLIENT

Name Name

Signature: Signature:

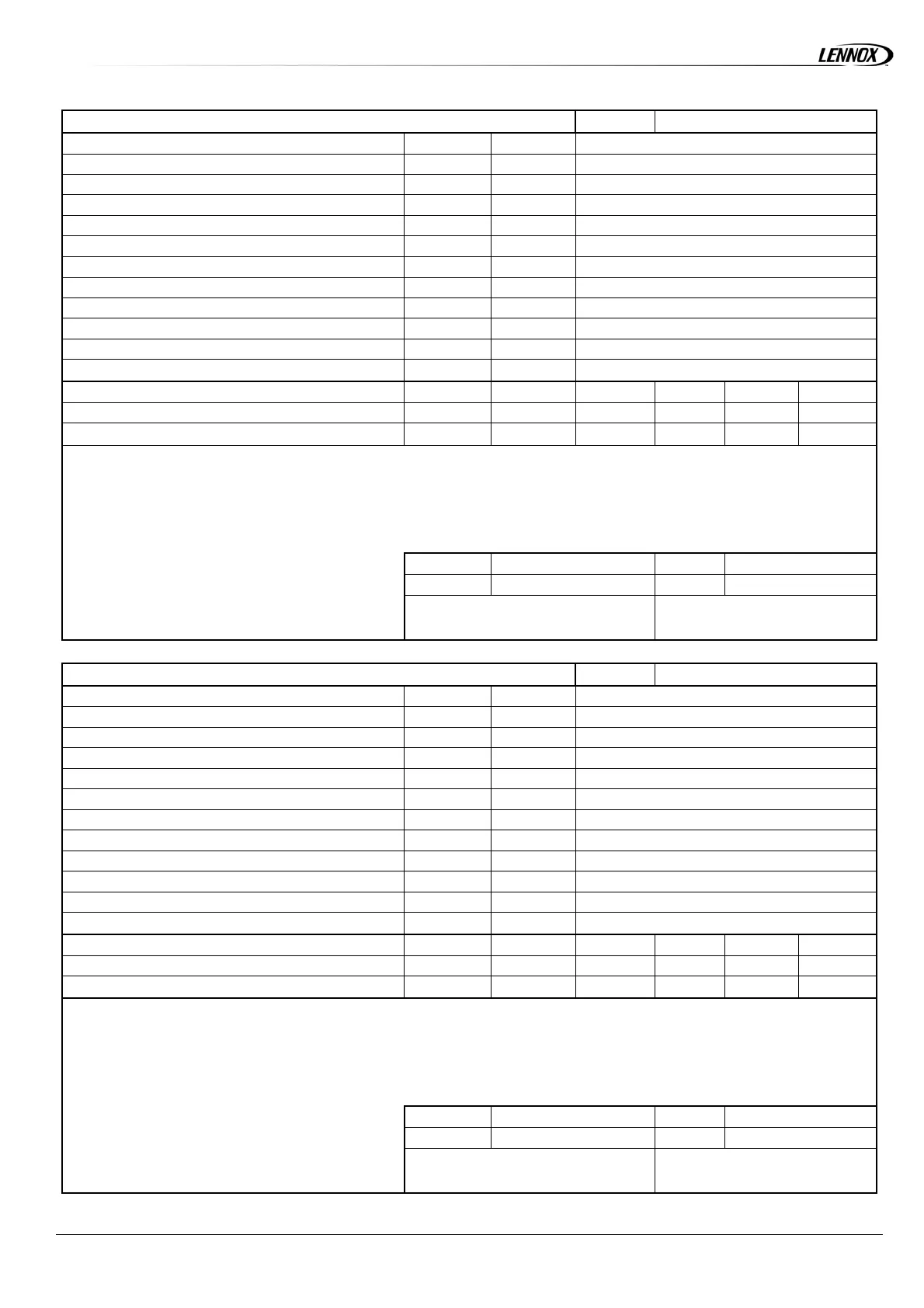

MAINTENANCE visit n° 2 Date

Y / N Value Comments

Unit general control (corrosion, damages…)

Exchanger cleaning

Leak test done

Oil acidity test carried

Replacement of filter drier cartridge

Water filters cleans

Evaporator pressure drop Kpa

Water condenser pressure drop Kpa

Glycol concentration level %

Unit operating parameters checked and in conformity

Fans currents level checked and in conformity

Compressors data CP1 CP2 CP3 CP4 CP5 CP6

Operating hours

Current at 100% load

Comments et remarks:

TECHNICIAN CLIENT

Name Name

Signature: Signature:

Loading...

Loading...