Page 14

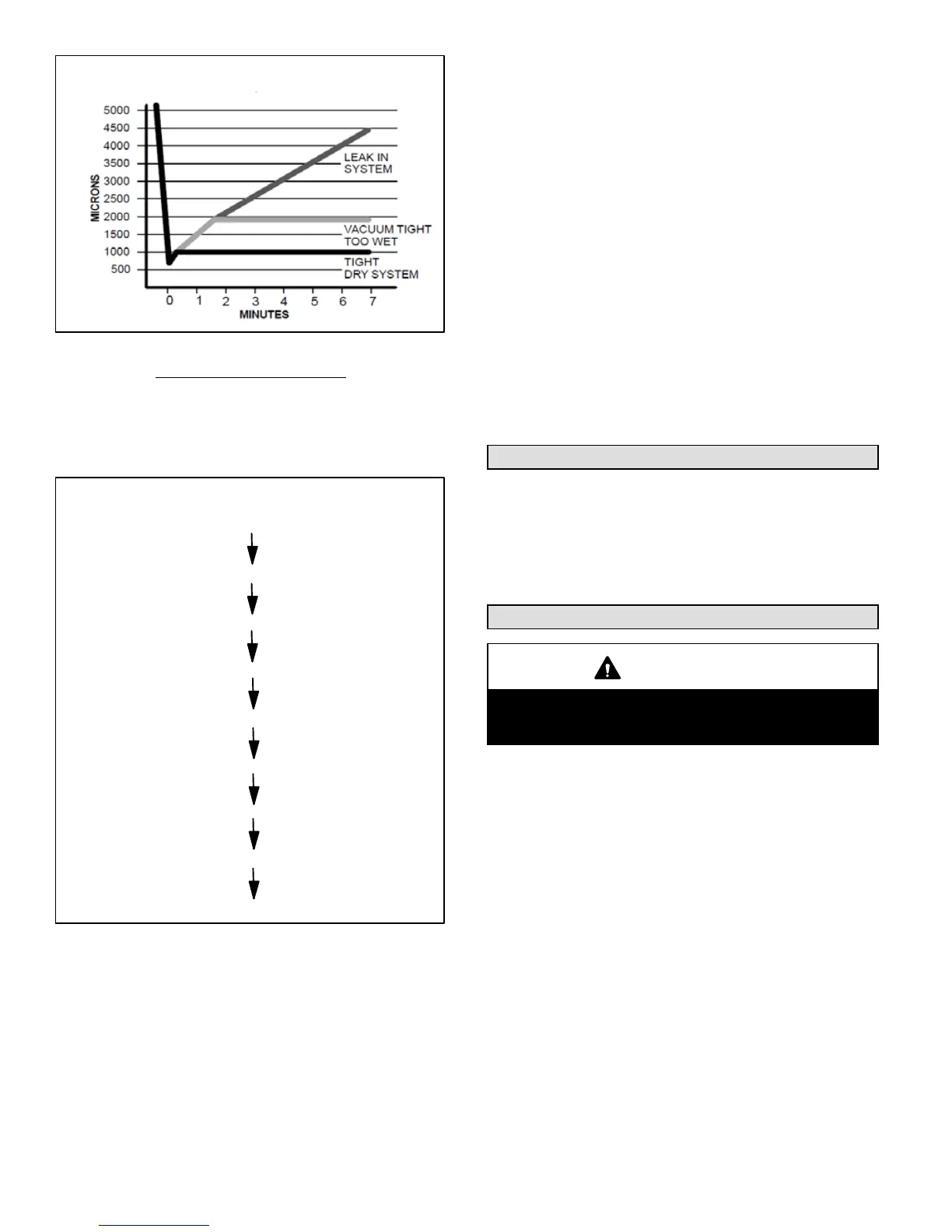

Deep Vacuum Gauge Response and

System Conditions

FIGURE 17

Triple Evacuation Method

The triple evacuation method should only be used when

system does not contain any water in liquid form and vacu

um pump is only capable of pulling down to 28 inches of

mercury (711mm Hg). Refer to figure 18 and proceed as

follows:

EVACUATE

BREAK VACUUM WITH DRY NITROGEN

WAIT

BREAK VACUUM WITH DRY NITROGEN

WAIT

EVACUATE

CHECK FOR TIGHT, DRY SYSTEM (IF IT HOLDS DEEP VACUUM)

CHARGE SYSTEM

Triple Evacuation Sequence

EVACUATE

FIGURE 18

1. Pull system down to 28 inches of mercury (711mm Hg)

and allow pump to continue operating for an additional

15 minutes.

2. Close manifold valves or valve at vacuum pump and

shut off vacuum pump.

3. Connect a nitrogen cylinder and regulator to system

and fill with nitrogen until system pressure is 2 psig.

4. Close nitrogen valve and allow system to stand for one

hour. During this time, dry nitrogen will diffuse through

out the system absorbing moisture.

5. Repeat this procedure as indicated in figure 18.

6. After the final evacuation sequence, confirm there are

no leaks in the system. If a leak is found, repeat the en

tire process after repair is made.

7. Reconnect the manifold gauge to the vacuum pump,

turn the pump on, and continue to evacuate the line set

and indoor unit until the absolute pressure does not

rise above 500 microns (29.9 inches of mercury) within

a 20-minute period after shutting off the vacuum pump

and closing the manifold gauge valves.

8. Disconnect the manifold hose from the vacuum pump

and connect it to an inverted cylinder of HFC*410A

positioned to deliver liquid refrigerant. Open the mani

fold gauge valve 1 to 2 psig in order to release the vac

uum in the line set and indoor unit.

9. Perform the following:

S Close manifold gauge valves.

S Shut off HFC*410A cylinder.

S Slowly open the service valves.

S Refer to the charging sticker on the unit to com

plete the outdoor unit installation.

Charging

The SL18XC1 unit is factory-charged with enough

HFC-410A refrigerant to accommodate a 15-foot length of

refrigerant piping. Charge should be checked and adjusted

using the tables provided on the charging procedure stick

er on the unit access panel. Detailed information is given in

the SL18XC1 Installation and Service Procedures manual,

which is available on LennoxPROS.com.

Homeowner Information

CAUTION

Before attempting to perform any service or mainte

nance, turn the electrical power to unit OFF at discon

nect switch.

In order to ensure peak performance, your system must be

properly maintained. Clogged filters and blocked airflow

prevent your unit from operating at its most efficient level.

Homeowner Maintenance

The following maintenance may be performed by the

homeowner.

S Contact a licensed professional HVAC technician to

schedule a yearly inspection and maintenance appoint

ment for your equipment.

S Check the indoor unit filter each month and replace the

filter, if necessary.

Have your Lennox dealer show you where your indoor

unit filter is located. It will be either at the indoor unit (in

stalled internal or external to the cabinet) or behind a re

turn air grille in the wall or ceiling. Check the filter monthly

and clean or replace it as needed.

Disposable filters should be replaced with a filter of the

same type and size.

S Check the indoor unit drain line for obstructions monthly

during the cooling season.

The indoor evaporator coil is equipped with a drain pan

Loading...

Loading...