Page 20

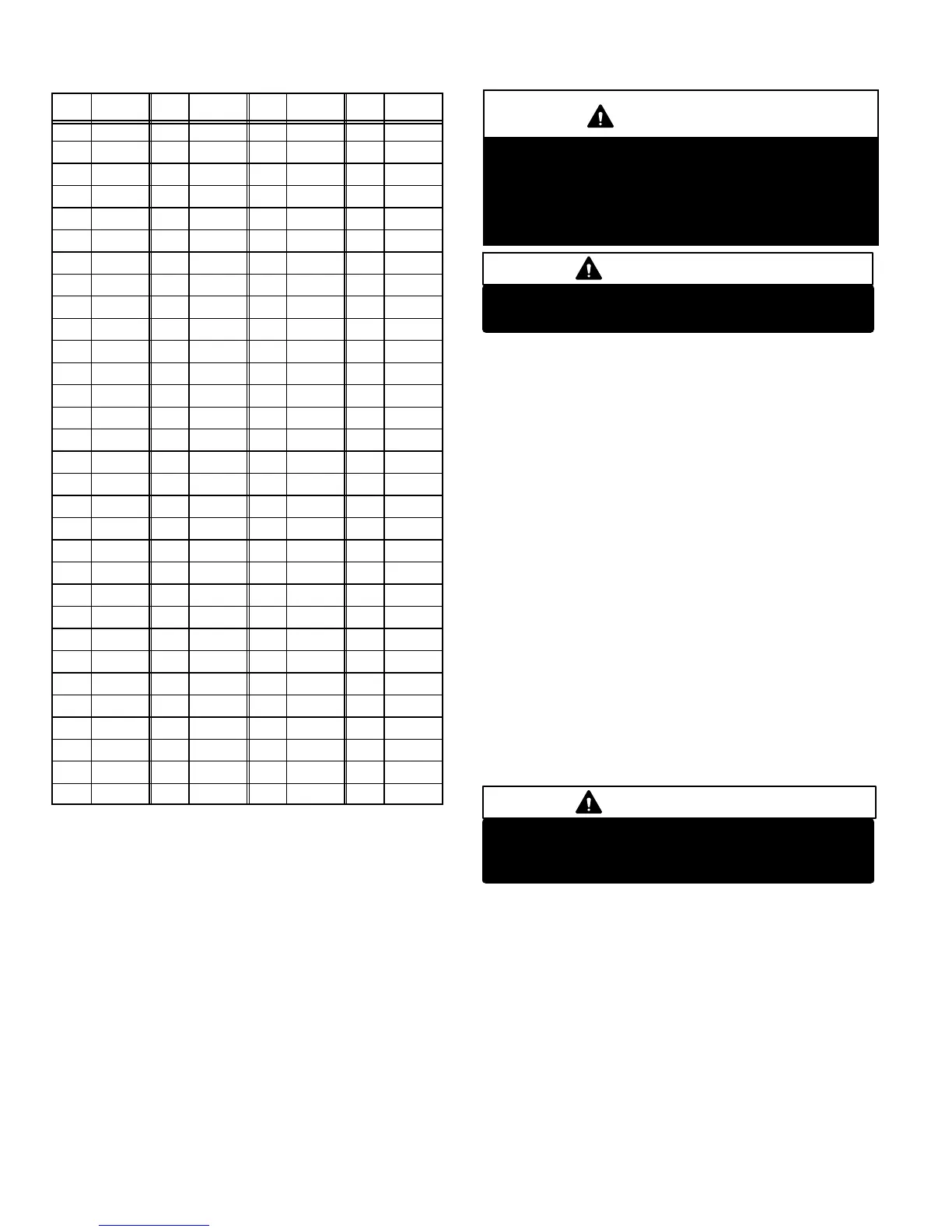

TABLE 8

HFC−410A Temp. (°F) − Pressure (Psig)

°F

Psig °F Psig °F Psig °F Psig

32 100.8 63 178.5 94 290.8 125 445.9

33 102.9 64 181.6 95 295.1 126 451.8

34 105.0 65 184.3 96 299.4 127 457.6

35 107.1 66 187.7 97 303.8 128 463.5

36 109.2 67 190.9 98 308.2 129 469.5

37 111.4 68 194.1 99 312.7 130 475.6

38 113.6 69 197.3 100 317.2 131 481.6

39 115.8 70 200.6 101 321.8 132 487.8

40 118.0 71 203.9 102 326.4 133 494.0

41 120.3 72 207.2 103 331.0 134 500.2

42 122.6 73 210.6 104 335.7 135 506.5

43 125.0 74 214.0 105 340.5 136 512.9

44 127.3 75 217.4 106 345.3 137 519.3

45 129.7 76 220.9 107 350.1 138 525.8

46 132.2 77 224.4 108 355.0 139 532.4

47 134.6 78 228.0 109 360.0 140 539.0

48 137.1 79 231.6 110 365.0 141 545.6

49 139.6 80 235.3 111 370.0 142 552.3

50 142.2 81 239.0 112 375.1 143 559.1

51 144.8 82 242.7 113 380.2 144 565.9

52 147.4 83 246.5 114 385.4 145 572.8

53 150.1 84 250.3 115 390.7 146 579.8

54 152.8 85 254.1 116 396.0 147 586.8

55 155.5 86 258.0 117 401.3 148 593.8

56 158.2 87 262.0 118 406.7 149 601.0

57 161.0 88 266.0 119 412.2 150 608.1

58 163.9 89 270.0 120 417.7 151 615.4

59 166.7 90 274.1 121 423.2 152 622.7

60 169.6 91 278.2 122 428.8 153 630.1

61 172.6 92 282.3 123 434.5 154 637.5

62 175.4 93 286.5 124 440.2 155 645.0

V − SERVICE AND RECOVERY

WARNING

Polyol ester (POE) oils used with HFC−410A refrig-

erant absorb moisture very quickly. It is very impor-

tant that the refrigerant system be kept closed as

much as possible. DO NOT remove line set caps or

service valve stub caps until you are ready to make

connections.

IMPORTANT

Use recovery machine rated for HFC−410A refriger-

ant.

If the XP14 system must be opened for any kind of service,

such as compressor or drier replacement, you must take

extra precautions to prevent moisture from entering the

system. The following steps will help to minimize the

amount of moisture that enters the system during recovery

of HFC−410A.

1 − Use a regulator−equipped nitrogen cylinder to break

the system vacuum. Do not exceed 5 psi. The dry nitro-

gen will fill the system, and will help purge any mois-

ture.

2 − Remove the faulty component and quickly seal the sys-

tem (using tape or some other means) to prevent addi-

tional moisture from entering the system.

3 − Do not remove the tape until you are ready to install

new component. Quickly install the replacement com-

ponent.

4 − Evacuate the system to remove any moisture and other

non−condensables.

The XP14 system MUST be checked for moisture any

time the sealed system is opened.

Any moisture not absorbed by the polyol ester oil can be re-

moved by triple evacuation. Moisture that has been ab-

sorbed by the compressor oil can be removed by replacing

the drier.

IMPORTANT

Evacuation of system only will not remove mois-

ture from oil. Drier must be replaced to eliminate

moisture from POE oil.

Loading...

Loading...