Page 51

XP16

Checklists

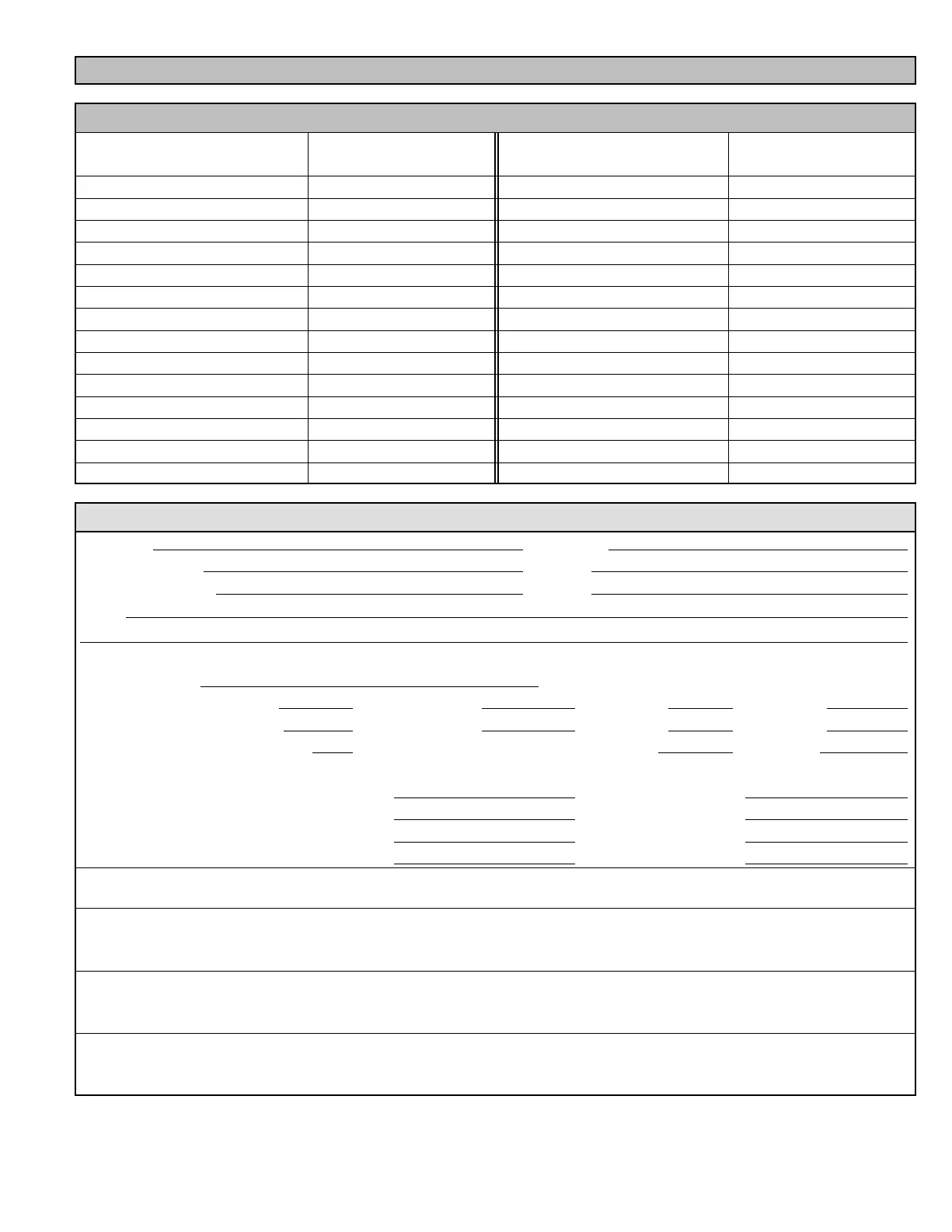

Two−Stage Modulation Compressors Field Operational Checklist

Unit Readings Y1 − First-Stage

Expected results during Y2

demand (Toggle switch On)

Y2 − Second-Stage

COMPRESSOR

Voltage Same

Amperage Higher

OUTDOOR UNIT FAN MOTOR

Amperage Same or Higher

TEMPERATURE

Ambient Same

Outdoor Coil Discharge Air Higher

Compressor Discharge Line Higher

Indoor Return Air Same

Indoor Coil Discharge Air Lower

PRESSURES

Suction (Vapor) Lower

Liquid Higher

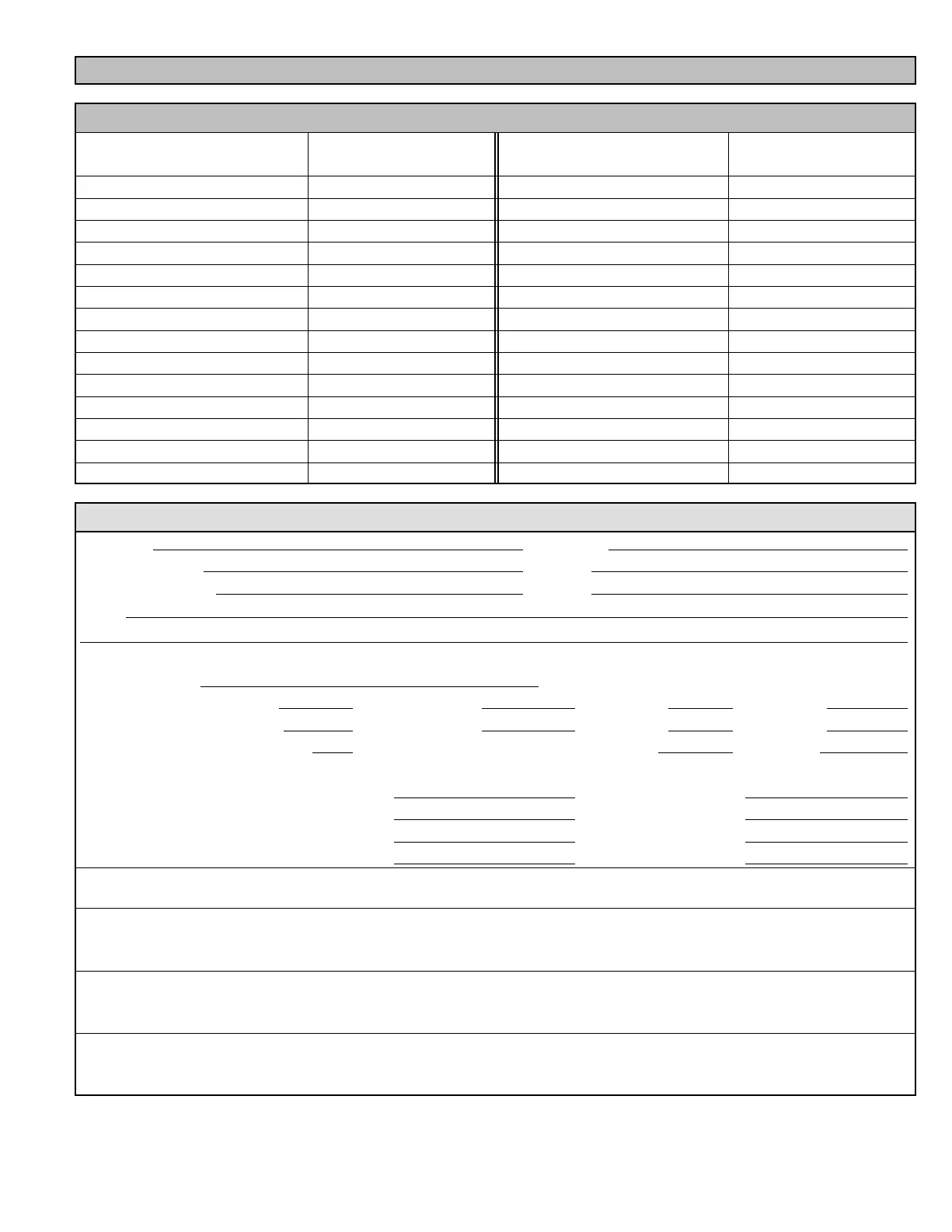

XP16 Start−Up and Performance

Customer Address

Indoor Unit Model Serial

Outdoor Unit Model Serial

Notes:

START UP CHECKS

Refrigerant Type:

1st Stage: Rated Load Amps Actual Amps Rated Volts Actual Volts

2nd Stage: Rated Load Amps Actual Amps Rated Volts Actual Volts

Outdoor Unit Fan Full Load Amps Actual Amps: 1st Stage 2nd Stage

COOLING MODE

Suction Pressure: 1st Stage: 2nd Stage:

Liquid Pressure: 1st Stage: 2nd Stage:

Supply Air Temperature: 1st Stage: 2nd Stage:

Temperature: Ambient: Return Air:

System Refrigerant Charge (Refer to manufacturer’s information on unit or installation instructions for required subcool-

ing and approach temperatures.)

Subcooling:

A

B

=

SUBCOOLING

Saturated Condensing Temperature (A)

minus Liquid Line Temperature (B)

Approach:

A

B

=

APPROACH

Liquid Line Temperature (A) minus

Outdoor Air Temperature (B)

Indoor Coil Temperature Drop (18 to 22°F)

A

B

=

COIL TEMP DROP

Return Air Temperature (A) minus

Supply Air Temperature (B)

Loading...

Loading...