Diagnoscs and fault eliminaon

Malfuncons

If faults occur during the operaon of the drive, the table below helps you to idenfy the

causes. If it is not possible to remedy the fault using the measures listed, please contact the

Lenze service department.

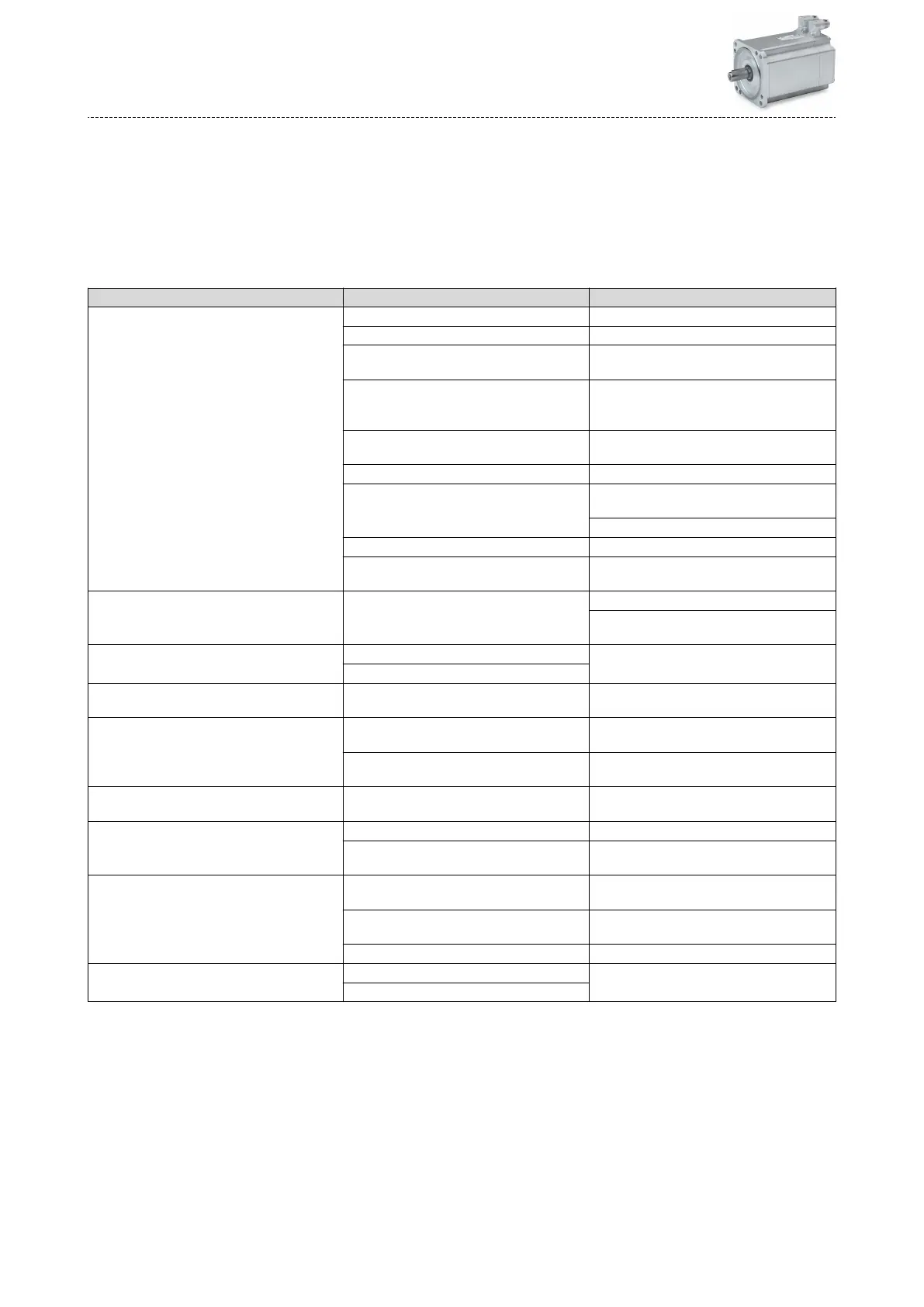

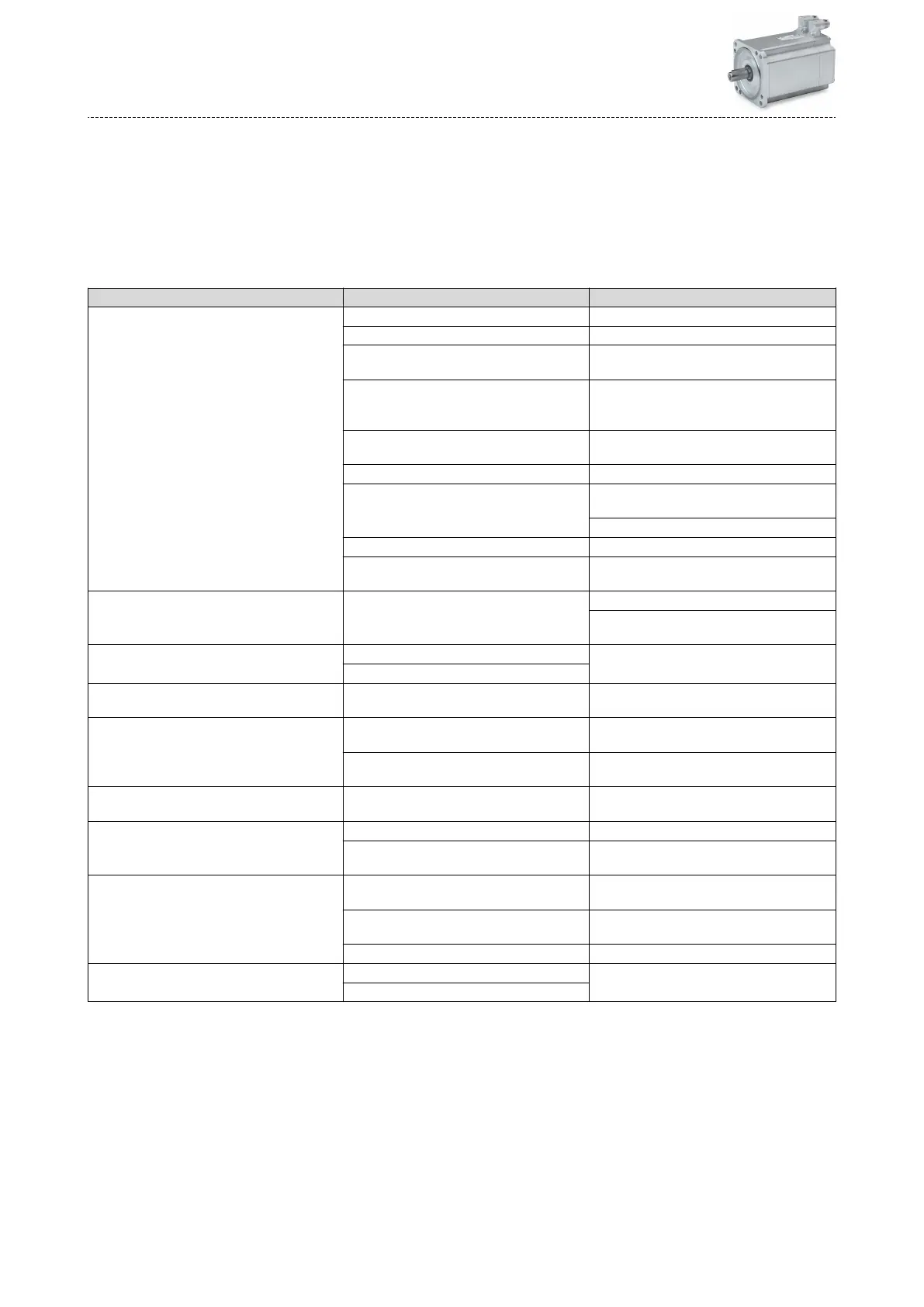

Error Possible causes Remedy

Motor too hot

Can only be evaluated by measuring the surface

temperature:

•

Non-venlated motors >140 °C

•

Externally venlated or self-venlated motors

> 110 °C

Insucient cooling air, blocked air ducts. Ensure unimpeded circulaon of cooling air

Preheated cooling air Ensure a sucient supply of fresh cooling air

Overload, with normal mains voltage the

current is too high and the speed too low

Use larger drive (determined by power

measurement)

Rated operang mode (S1 to S8 IEC/EN

60034-1) exceeded

Adjust rated operang mode to the specied

operang condions. Determinaon of correct

drive by expert or Lenze customer service

Loose contact in supply cable (temporary

single-phase operaon!)

Tighten loose contact

Fuse has blown (single-phasing!) Replace fuse

Overload of the drive Check load and, if necessary, reduce by means

of longer ramp-up mes

Check winding temperature

Heat dissipaon impeded by deposits Clean surface and cooling ns of the drives

Heat dissipaon hindered by thermally

insulated aachment

Note the cooling eect of the mounng ange

during project planning

Motor suddenly stops and does not restart Overload monitoring of the inverter is acvated Check inverter sengs

Reduce load caused by longer acceleraon

mes

Incorrect direcon of rotaon of the motor,

correct display on the inverter

Motor cable with reverse polarity Check and correct polarity

Polarity of encoder cable reversed

Motor rotates normally but does not reach the

expected torque

Motor cable interchanged cyclically

Not all motor phases connected

Connect the phases at the motor cable

connecon correctly

Motor turns in one direcon at maximum speed

in an uncontrolled manner

Motor cable interchanged cyclically Check motor connecon and, if necessary,

correct

Polarity of encoder cable reversed Check encoder connecon and, if necessary,

correct

Motor slowly rotates in one direcon and is not

inuenced by the inverter

Polarity of motor cable and encoder cable

reversed

Check and correct polarity

Irregular running Insucient shielding of motor or resolver cable Checking shielding and earth connecon

Inverter gain too large Adjust the gains of the controllers (see

operang instrucons for the inverter)

Vibraons Insuciently balanced coupling elements or

machine

Rebalance

Inadequate alignment of drive train Realign machine unit, check foundaon, if

necessary.

Loose xing screws Check and ghten screw connecons

Running noises Foreign parcles inside the motor Repair by the manufacturer, if necessary

Bearing damage

Diagnoscs and fault eliminaon

Malfuncons

30

Loading...

Loading...