300598802_002_C0 - 10/2016 - © Leybold 7

Areas of application

1 Description

TRIVAC

®

T pumps are oil-sealed dual-stage rotary vane pumps. The number

in the type designation (4, 8, 16 or 30) indicates the pumping speed in m

3

·h

-1

.

TRIVAC

®

T pumps are capable of pumping gases and vapours and evacuat-

ing vessels or vacuum systems down into with the medium vacuum range.

The standard versions of the pump are not suited for pumping of oxygen ex-

ceeding the concentration as found in the atmosphere, and are also not suited

for pumping of hazardous gases or extremely aggressive or corrosive media.

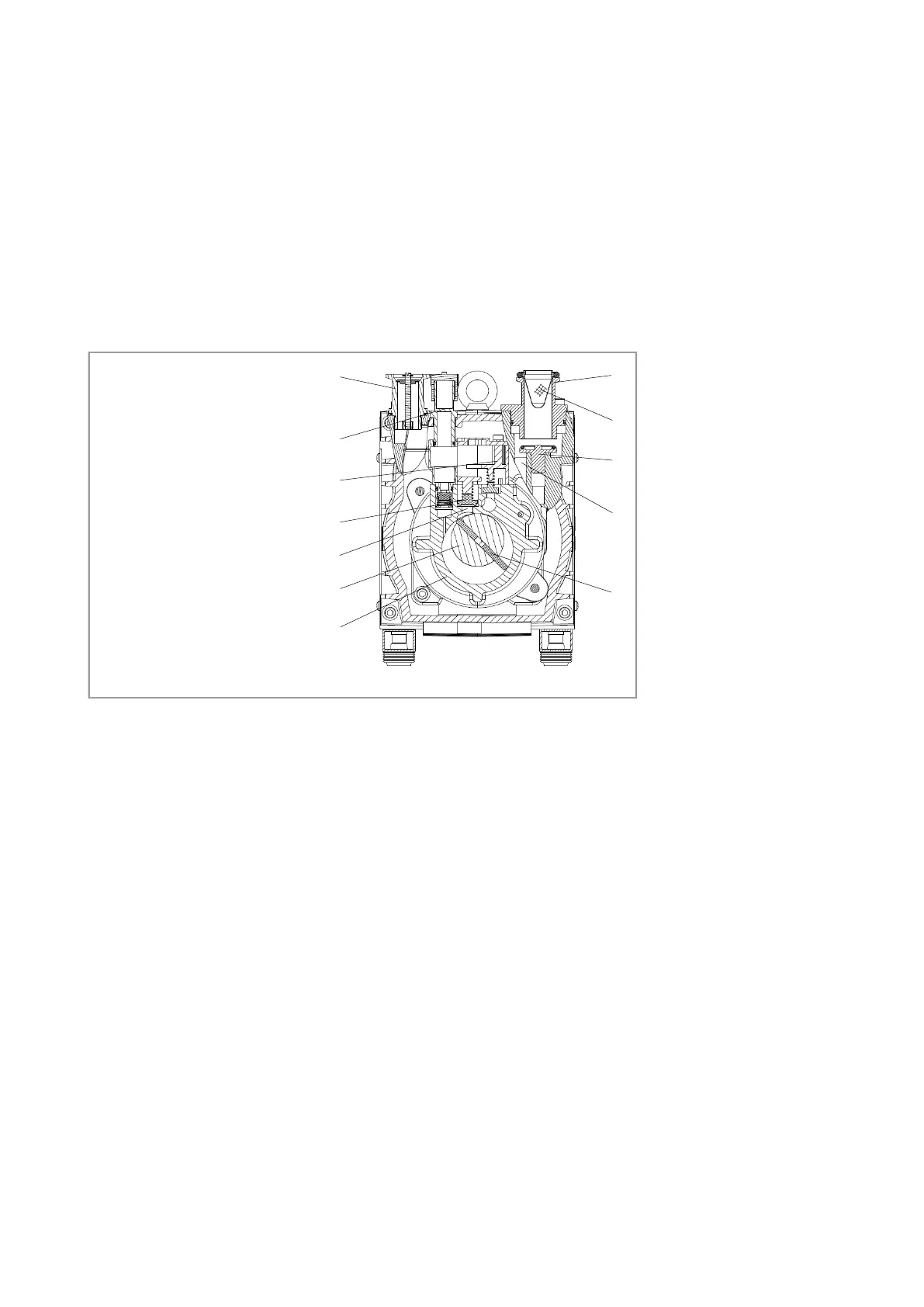

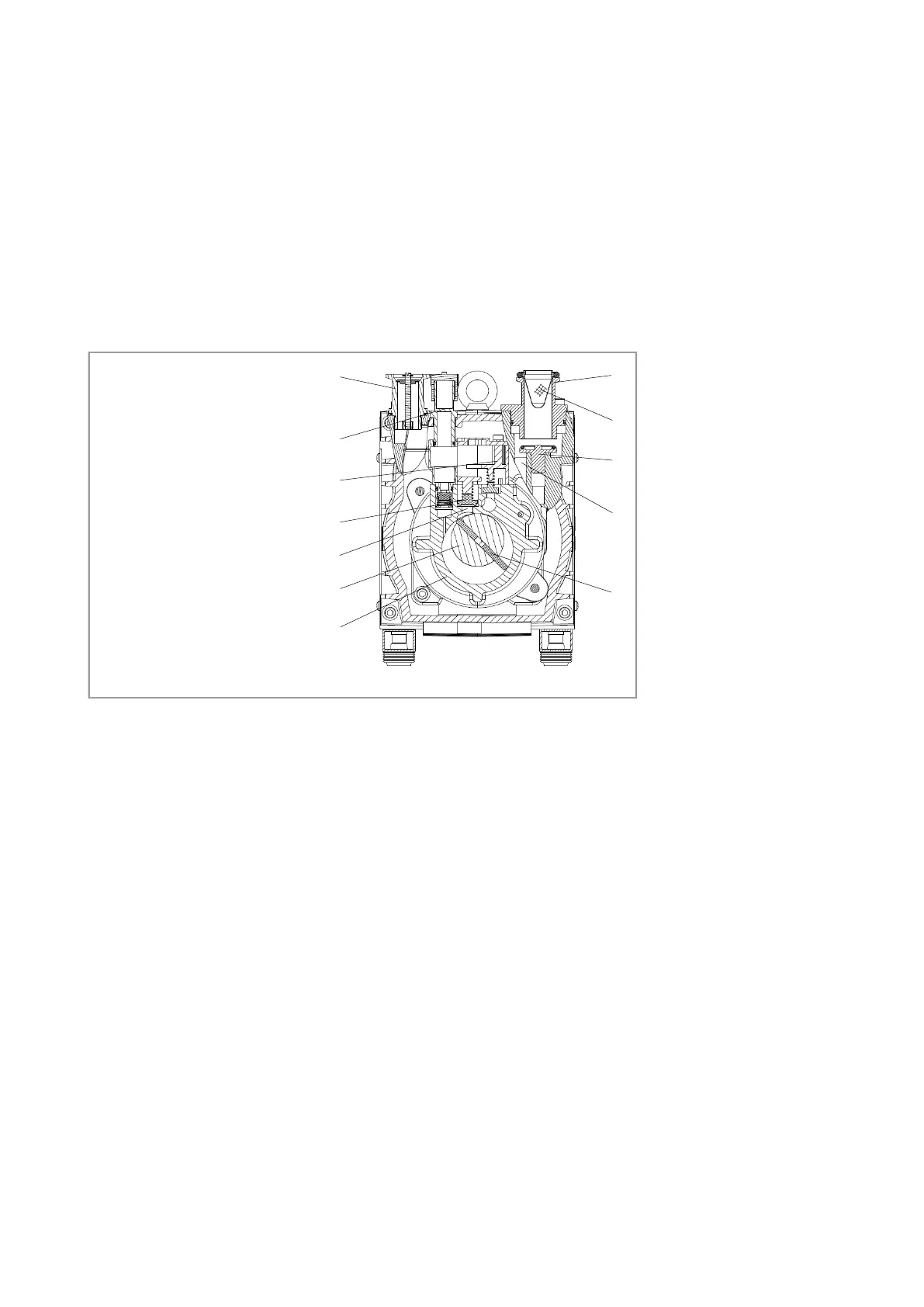

1.1 Function

The rotor (1/7), mounted eccentrically in the pump housing (1/6), has two radi-

ally sliding vanes (1/5) which divide the pump chamber into several compart-

ments. The volume of each compartment changes periodically with the rotation

of the rotor.

As a result, gas is sucked in at the intake port (1/1). The gas passes through

the dirt trap sieve (1/2), flows past the open anti-suckback valve (1/3) and then

enters the pump chamber. In the pump chamber, the gas is passed on and

compressed, after the inlet aperture is closed by the vane.

The oil injected into the pump chamber is used for sealing and lubricating. The

slap noise of the oil in the pump which usually occurs when attaining the ulti-

mate pressure is prevented by admitting a very small amount of air into the

pump chamber. Pump is already with silencing device.

The compressed gas in the pump chamber is ejected through the exhaust

valve (1/9). The oil entrained in the gas is coarsely trapped in the internal

splashguard(1/10); there the oil is also freed of mechanical impurities. The gas

leaves the TRIVAC

®

T through the exhaust port.

During compression, a controlled amount of air - the so-called gas ballast - can

be allowed to enter the pump chamber by opening the gas ballast valve. The

gas ballast stops condensation of vapours in the pump chamber up to the limit

of the water vapour tolerance as specified in the technical data for the pump.

Description

1 Intake port

2 Dirt trap

3 Anti-suckback valve

4 Intake channel

5 Vanes

6 Pump chamber

7 Rotor

8 Exhaust channel

9 Exhaust valve

10 Splashguard

11 Gas ballast

12 Exhaust port

Fig. 1 Sectional drawing of the TRIVAC

®

T

7

6

5

1

2

3

4

8

10

12

11

9

Loading...

Loading...