Loading...

Loading...

Do you have a question about the Makita 3621 and is the answer not in the manual?

| Brand | Makita |

|---|---|

| Model | 3621 |

| Category | Network Router |

| Language | English |

Crucial safety guidelines applicable to all tools for preventing injury.

Guidelines for maintaining a safe and clean work environment during tool operation.

Precautions related to the tool's electrical components and power supply.

Emphasizes operator focus and common sense for safe tool operation.

Guidelines on attire to prevent entanglement with moving parts.

Measures to prevent unintentional tool activation before use.

Maintaining proper footing, balance, and avoiding overreaching for control.

Mandatory use of eye protection and other safety gear for specific conditions.

Proper methods for securing workpieces to prevent instability and loss of control.

Using the correct tool for the application for better and safer results.

Safety measure against using a tool with a faulty or unresponsive switch.

Procedure for unplugging the tool before adjustments or accessory changes.

Safe storage practices for tools to prevent unauthorized use.

Importance of keeping tools sharp, clean, and well-maintained for control.

Inspecting for damaged parts or conditions affecting tool operation.

Caution against using non-manufacturer recommended accessories.

Requirement for authorized personnel for tool repairs and maintenance.

Ensuring safety and reliability by using only genuine Makita replacement parts.

Safety tip for avoiding shock when cutting near hidden wiring or the cord.

Recommendation for hearing protection during extended periods of operation.

Careful handling and checking bits for damage before operation.

Instruction to remove nails from workpieces before routing.

Essential technique for stable and controlled router operation.

Ensuring the bit is clear of the workpiece before starting the tool.

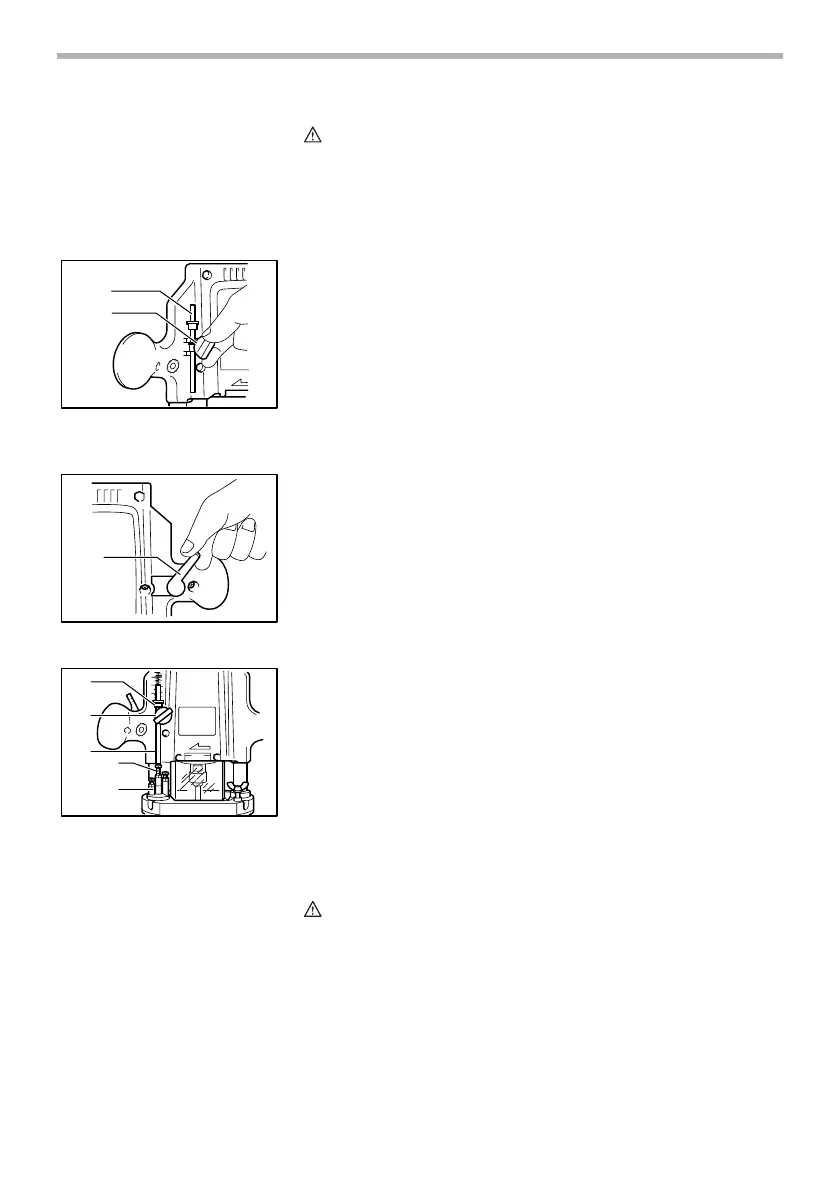

Step-by-step guide for setting the desired cutting depth.

Explanation of the stopper block's function and adjustments for depth.

Procedure for adjusting the tool's lock lever for stability.

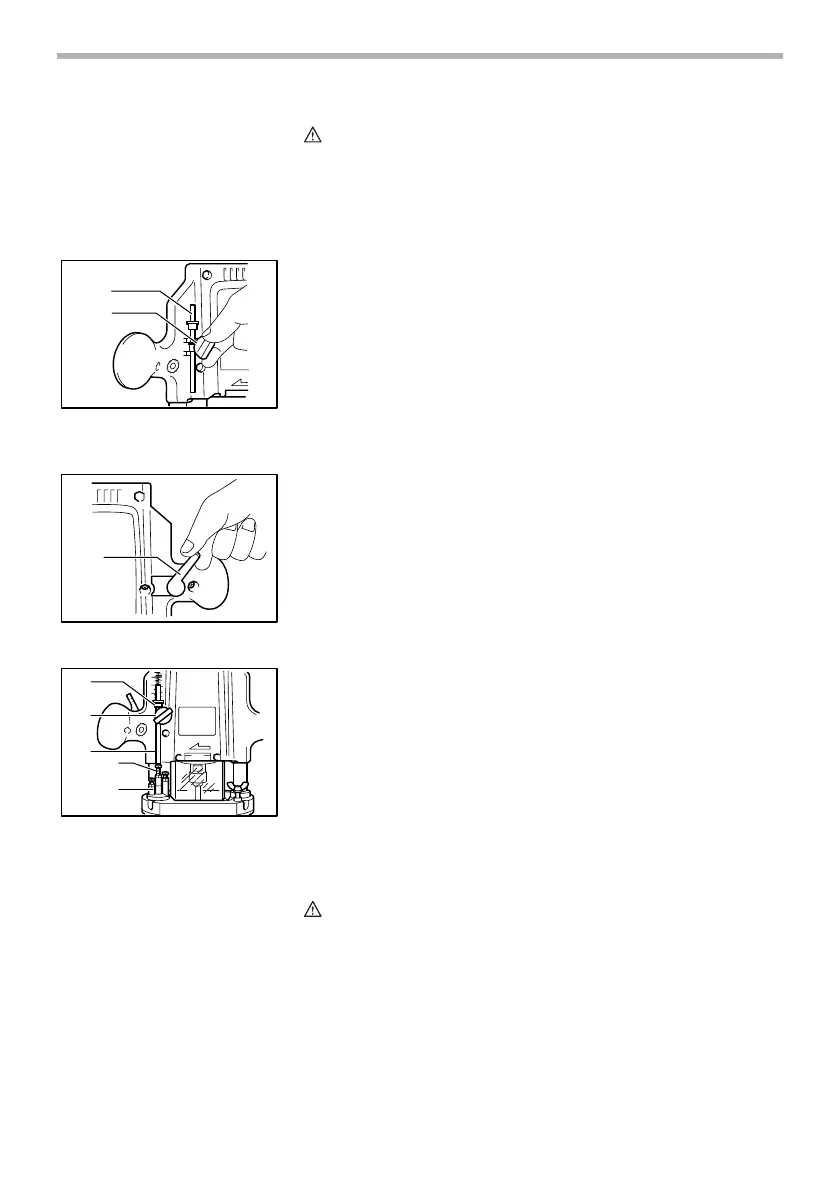

Procedure for securely installing and removing router bits.

Instructions for attaching the dust nozzle for cleaner operation.